Overcoming Environmental Challenges That Affect Metal Detection

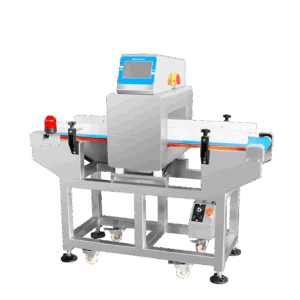

Introduction Importance of Reliable Metal Detection in Food Production Lines Reliable metal detection is a critical component of modern food production, ensuring food safety and protecting consumers from potential harm. Food industry metal detectors are widely used to identify contaminants such as ferrous, non-ferrous, and stainless-steel particles in packaged and unpackaged products. Understanding how a