Seafood Industrial Solution

This X-ray inspection system is highly effective at detecting foreign objects in a wide range of beverages, such as bottled milk, canned juices, carbonated drinks, and other packaged liquids.

Introduction to Seafood Industry Challenges

Detection of Fine Fish Bones and Soft Tissues

Seafood frequently contains small, fine bones that are difficult to detect. Advanced X-ray systems with high-resolution, dual-energy imaging enhance the visibility of these small bones, enabling accurate detection even in dense or layered seafood products.

Varied Shapes, Sizes, and Textures

Seafood comes in diverse forms, from whole fish to fillets and shellfish, each with different textures and densities. Intelligent X-ray algorithms adjust for these variations, ensuring consistent inspection accuracy across a wide range of shapes and product types.

Detection of Non-Metallic Contaminants

Besides metallic contaminants, seafood may contain non-metallic foreign objects like shells, bones, or hard plastics. X-ray technology designed for multi-material detection can identify these non-metallic contaminants, enhancing safety for seafood products.

Packaging Complications with Foil or Dense Wrapping

Many seafood products are packaged in opaque or aluminum-lined materials that obstruct standard detection. X-ray inspection systems with the capability to penetrate dense or metallic packaging ensure accurate inspection without unwrapping products.

Variability in Temperature and Humidity Levels

Seafood processing often occurs in cold or humid environments to preserve freshness, which can impact inspection accuracy. X-ray systems with stable performance at low temperatures and anti-condensation features are optimized for such conditions, maintaining reliability in cold storage.

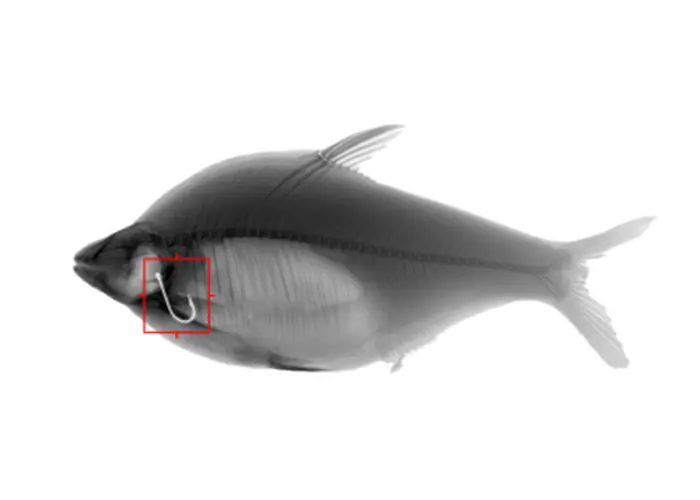

Contaminants from Processing Equipment

Seafood processing can introduce contaminants like metal fragments from machinery or fish hooks. X-ray systems equipped to detect a broad range of foreign objects, including small metal fragments, improve contamination control across the production line.

Core Technologies of Seafood X-Ray Inspection Systems

FDX

Foodman employs FDX technology, which integrates industry-leading dual-energy TDI high-resolution detectors with advanced dual-energy image analysis algorithms and deep learning techniques. This combination enables Foodman systems to perform precise material analysis, identify low-density impurities, and detect morphological features with exceptional accuracy. By utilizing FDX technology, Foodman enhances the detection capabilities of its X-ray inspection systems, ensuring higher efficiency, reliability, and safety in food processing and packaging.

FIAP

Foodman utilizes FIAP, which leverages advanced AI algorithms and deep learning techniques to enhance detection performance. By analyzing a vast amount of image data, FIAP significantly improves processing speed and detection accuracy. This technology ensures that Foodman’ s X-ray inspection systems can detect even the most subtle irregularities in food products, providing faster, more reliable results while maintaining the highest standards of quality and safety in food production.。

AI

Foodman incorporates advanced AI technology into its systems to optimize detection and quality control. By utilizing AI algorithms, Foodman’ s X-ray inspection systems can analyze vast amounts of data quickly and accurately. The AI-driven approach enhances the system’s ability to identify even the smallest contaminants or irregularities in food products, improving detection precision and operational efficiency. This integration of AI ensures consistent, high-quality results while reducing human error, making Foodman a trusted solution for food safety and quality assurance.

Choose the Right Detect Machine for Your Seafood Line

Overview of different Foodman X-ray machines suitable for various seafood types

X-Ray Inspection System For Large Fish Bone

It is applied in fish meat inspection such as octopus to detect foreign objects, ensuring the safety and quality of the product..

X-Ray Inspection System For Tiny Fish Bone

Used for fish meat testing such as cod, it helps detect foreign bodies, ensuring a safe and high-quality product.

X-Ray Inspection System For Packaged Products

It is used in fish meat testing such as tuna to identify foreign matter, ensuring product safety and quality.

Single Beam Side Scan X-Ray Inspection System FXR-C180

It serves to identify impurities in fish meat such as tilapia, enhancing both product quality and safety.

Foodman Amazing Clients