Understanding the Basics of X-Ray Inspection

In today’ s fast-paced manufacturing and food production environments, X-Ray inspection has become an essential tool for quality control and contamination detection. Whether integrated into a packaging line or deployed as a standalone unit, an X-Ray inspection system plays a critical role in ensuring product integrity and safety. These X-Ray inspection machines use advanced imaging technology to detect hidden contaminants—such as metal fragments, glass shards, stones, and dense plastics—that are invisible to traditional visual or metal detectors.

How X-Ray Inspection Works

At its core, X-Ray inspection is based on the principle of density differentiation. As products pass through the X-Ray beam, denser materials absorb more X-rays and appear as darker areas on the resulting image. This contrast allows the system to identify and isolate foreign materials that don’t belong in the product.

Typical applications span across industries:

In the food industry, to find bones in meat or glass in packaged goods.

In pharmaceuticals, to detect broken tablets or missing components in blister packs.

In manufacturing, for detecting defects in sealed containers or verifying fill levels.

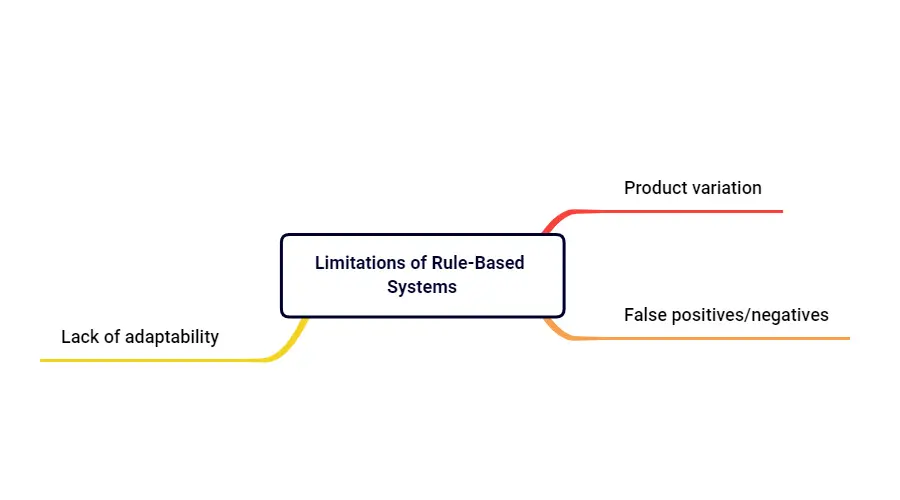

Limitations of Rule-Based Systems

Traditional X-Ray inspection systems often rely on rule-based algorithms that work with fixed parameters, such as shape, size, or grayscale thresholds. While effective in controlled conditions, these systems struggle with:

Product variation: Changes in product size, shape, or texture can confuse fixed algorithms.

False positives/negatives: Rule-based detection can either miss real contaminants or flag harmless items incorrectly.

Lack of adaptability: Reconfiguring for new products or packaging types requires manual tuning, reducing efficiency

What is Deep Learning?

As industries strive for greater accuracy in detecting foreign materials and product anomalies, deep learning is rapidly becoming a game-changer in the field of X-Ray inspection. Unlike traditional rule-based systems, deep learning enables machines to “learn” from vast amounts of data and improve over time without manual reprogramming.

From Rule-Based to Learning-Based Systems

Deep learning is a subset of machine learning based on artificial neural networks—algorithms inspired by the structure and function of the human brain. These networks consist of layers of interconnected nodes (neurons), which process and transform input data to learn complex patterns and features.

In the context of X-Ray inspection, this means that instead of relying on fixed rules, a system powered by deep learning is trained on thousands of labeled X-ray images. The model learns to identify subtle differences between safe products and those containing foreign bodies. Over time, with more data, its accuracy improves, making it more reliable than static, rule-driven systems.

Why Deep Learning Fits X-Ray Inspection

Deep learning is particularly well-suited for X-Ray inspection systems because of its ability to handle:

Variations in product shape and texture: Whether it’ s irregular cuts of meat, different bottle types, or complex packaging, the model can learn to recognize these differences without the need for manual adjustment.

Subtle differences in density: Traditional systems might miss low-density contaminants like rubber or certain plastics. Deep learning models can be trained to detect these more reliably through pixel-level pattern recognition.

Continuous performance improvement: As more inspection data is collected and used for training, the model becomes smarter—improving detection accuracy and reducing false positives and false negatives over time.

By shifting from static rules to adaptive learning, deep learning allows X-Ray inspection machines to operate with more flexibility and intelligence—an essential evolution for modern food safety and quality control.

Real-World Applications of Deep Learning in X-Ray Detection

Deep learning is no longer just a buzzword—it’s transforming the capabilities of X-Ray inspection systems across industries. By analyzing thousands of labeled X-ray images, deep learning models learn to recognize even the most subtle differences between normal and contaminated products. Here are some key areas where deep learning is making a tangible difference.

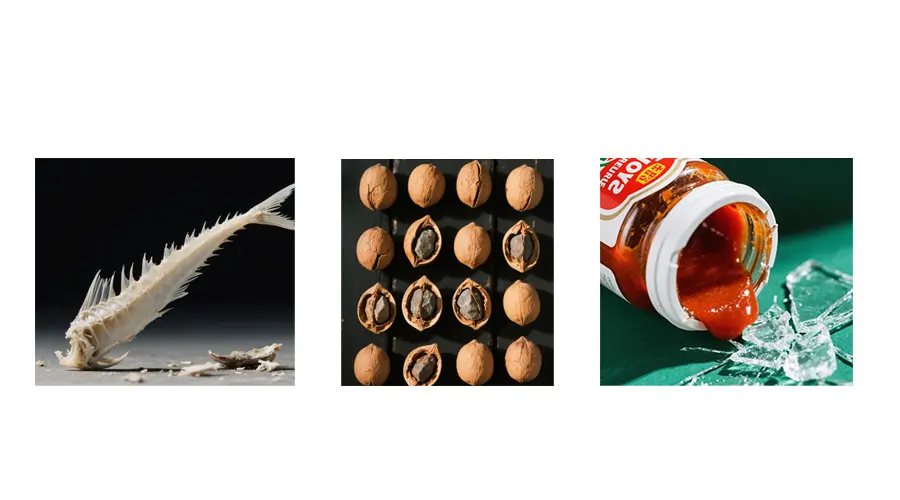

Foreign Body Detection in Complex Food Products

In food safety, identifying foreign bodies in visually complex or irregular products has always been challenging. Traditional rule-based systems often fall short when contaminants are low-density or hidden within dense food matrices. Deep learning offers a new level of precision in detection, particularly for:

Bone fragments in fish

Fish bones vary in size, shape, and density, making them difficult to detect consistently. Deep learning algorithms can be trained on diverse datasets to accurately flag even the smallest bones without excessive false alarms.

Stones in nuts

Nuts often vary in shape and density, and small stones can be easily missed by older detection technologies. Deep learning models are adept at distinguishing stones from nuts by learning complex visual and textural cues.

Glass shards in sauce packs

Packaging and sauce textures can interfere with detection. Deep learning-powered X-Ray inspection machines can identify foreign glass materials despite challenging imaging conditions caused by liquid content and layered packaging.

Adaptive Inspection for Product Variability

In real-world manufacturing and food processing, no two products are exactly the same. Variations in package types, product densities, and moisture levels are common challenges that can impact the accuracy of traditional X-Ray inspection systems. These systems often rely on rigid, rule-based thresholds, which can lead to inconsistent results — especially when product conditions deviate from the norm.

Deep learning-enhanced X-Ray inspection systems bring a new level of adaptability. By learning from thousands of real production images, these systems develop a more nuanced understanding of acceptable product variation. For example:

Package types: Whether it’ s vacuum-sealed fish, glass jars of sauce, or plastic-wrapped meat, the system can distinguish between packaging artifacts and actual foreign bodies.

Density differences: Products like nuts, sausages, or multi-layer sandwiches often have uneven density. Deep learning models are able to tolerate this variability while still flagging true contaminants.

Moisture variations: High humidity levels or internal product moisture can interfere with detection. AI-based systems can adapt over time, learning to ignore moisture-related noise.

Compared to traditional systems, these smart inspection machines offer significantly improved reliability, particularly in complex production environments. The result is more accurate detection, fewer false positives, and greater confidence in your quality assurance process — even when your products are far from uniform.

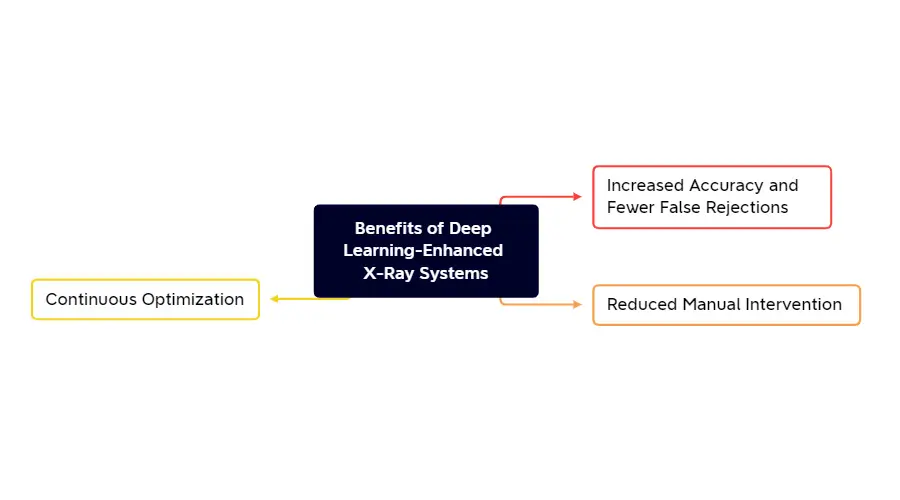

Benefits of Deep Learning-Enhanced X-Ray Systems

Integrating deep learning into X-Ray inspection systems brings tangible improvements across food, pharmaceutical, and packaging industries. Unlike traditional rule-based systems, deep learning models continue to learn and adapt—driving both operational efficiency and inspection reliability. Here’s a breakdown of the key benefits:

Increased Accuracy and Fewer False Rejections

Deep learning enables X-Ray inspection machines to distinguish between real contaminants and product variations with far greater precision. Traditional systems often rely on fixed thresholds, which can result in either undetected contaminants or unnecessary product rejection.

Real-world example: After implementing a deep learning-based inspection system, a seafood processor reduced false rejection rates by 35% while increasing detection sensitivity by 20%—resulting in both better food safety and less product waste.

By minimizing false positives and improving true detection rates, manufacturers can maintain compliance and reduce the cost associated with rejected goods.

Reduced Manual Intervention

One of the standout advantages of deep learning-enhanced systems is their ability to self-adjust without constant human input.

Smart parameter adjustments: The system can adapt inspection thresholds based on live image feedback and pattern recognition, reducing reliance on manual calibration.

Less operator training required: Since the system handles complex analysis internally, operators don’t need to be X-ray or programming experts. This makes the technology easier to deploy and scale across production facilities.

This automation reduces operational downtime and lowers the skill barrier, enabling faster onboarding and more consistent performance.

Continuous Optimization

Deep learning models don’ t just maintain performance—they improve it over time.

Model updates through new data inputs: As the system processes more images, it can incorporate new examples into its training set. This allows it to refine its understanding of both acceptable variations and emerging contaminant types.

Adaptability to new products: Whether it’s a new packaging format or a seasonal variation in product density, the model can be retrained or fine-tuned with minimal disruption.

This continuous improvement loop ensures that your X-Ray inspection machine stays accurate and relevant, even as production environments evolve.

Challenges and Considerations

While deep learning-powered X-Ray inspection systems offer transformative benefits, their implementation also comes with specific challenges that manufacturers must address. From data quality to regulatory compliance, successful deployment requires a strategic approach.

Need for High-Quality Training Data

At the heart of any deep learning model is the training data. For an X-Ray inspection system to reliably detect foreign bodies across different products and conditions, the data used must be both comprehensive and accurately labeled.

Importance of diversity: Models trained on a narrow dataset may perform poorly when faced with product variations, such as different shapes, textures, or packaging formats.

Labeling accuracy: Incorrectly labeled images (e.g., mistaking a bone for normal product content) can degrade model performance and increase error rates in real-world inspections.

To ensure robustness, manufacturers must invest in building large, diverse, and meticulously labeled datasets—often requiring collaboration between quality assurance teams and AI experts.

Processing Power and Cost

Deep learning algorithms demand substantial computational resources, particularly during training and real-time inference.

Hardware requirements: Running a deep learning model on an X-Ray inspection machine may require GPUs, edge computing modules, or dedicated AI processors, all of which increase the initial investment.

System investments: In addition to hardware, there are costs related to software development, maintenance, and potential retraining of models as product lines evolve.

While costs are decreasing as technology advances, manufacturers must still balance performance benefits with budget constraints.

Regulatory and Validation Hurdles

In regulated industries like food and pharmaceuticals, any system impacting product safety must meet strict compliance standards.

Validation challenges: Deep learning systems are not always “transparent” in how they reach conclusions, which can complicate validation processes under standards like HACCP or FDA guidelines.

Documentation and traceability: Authorities may require documented evidence of model performance, training data origin, and regular calibration schedules—demanding rigorous system tracking and reporting mechanisms.

To meet these requirements, companies must ensure their AI-powered systems are not only accurate but also explainable and auditable.

Conclusion

Deep learning is revolutionizing the capabilities of X-Ray inspection systems, transforming them from reactive tools into predictive solutions. By enabling machines to “learn” from data, these systems now detect subtle patterns and variations that traditional rule-based systems might miss.

This shift marks a significant leap forward in food safety, pharmaceutical quality assurance, and manufacturing accuracy. Smarter detection algorithms reduce false rejections, adapt to changing product conditions, and require less manual oversight—paving the way for a more efficient and reliable production line.

As industries move toward intelligent automation, now is the time to explore the integration of deep learning-powered X-Ray inspection machines into your quality control workflow. The result? A safer, more adaptive, and future-ready production environment.

Ready to upgrade your inspection line? Contact us to learn how our advanced systems can enhance your product quality and operational confidence.

FAQ

Q1: How is a deep learning-based X-Ray inspection system different from a traditional one?

A: Traditional systems rely on fixed rules (e.g., grayscale threshold or object size), which limits their adaptability. Deep learning systems are trained on large datasets of real images, enabling them to recognize complex patterns and variations—leading to higher accuracy, better adaptability, and fewer false rejections.

Q2: Can deep learning detect low-density contaminants like plastic or rubber?

A: Yes. One of the key strengths of deep learning is its ability to detect subtle differences in pixel intensity and structure. This makes it more effective than conventional systems in identifying low-density contaminants such as soft plastics, rubber, or even bones in fish.

Q3: What kind of products benefit the most from deep learning-powered X-Ray inspection?

A: Products with high variability in shape, density, or packaging—such as seafood (fish bones), nuts (stones), and complex packaged goods (glass in sauce packs)—are ideal candidates. These are scenarios where traditional systems often produce unreliable results.