Introduction

In today’s competitive seafood industry, food quality and seafood quality control have become top priorities for producers striving to meet stringent safety standards and growing consumer expectations. Ensuring that every product is free from contaminants is not only critical for public health but also essential for maintaining brand reputation in both domestic and international markets. To achieve this, more and more seafood processors are turning to X-Ray inspection as a reliable and intelligent solution. Advanced X-Ray inspection systems are capable of detecting a wide range of foreign objects—including bones, metal, glass, and shell fragments—regardless of their location within the product. By integrating X-Ray inspection machines into their production lines, companies can improve detection accuracy and reduce the risk of costly recalls. Today’s state-of-the-art X-Ray inspection equipment offers a non-destructive, highly efficient method for upholding quality assurance and food safety in seafood processing.

Common Contaminants in Seafood Processing

Ensuring the purity and safety of seafood products is a major concern for processors and suppliers around the world. The complex nature of seafood—ranging from its variable textures to its high moisture content—makes it especially vulnerable to foreign body contamination. Understanding the types of contaminants and their potential impact is crucial for improving detection accuracy and upholding product integrity.

Types of Foreign Bodies

In seafood processing, a variety of foreign bodies can unintentionally make their way into the final product. These contaminants can originate from the raw material itself or from equipment and packaging processes:

Fish bones: Naturally occurring in fish, small bones are one of the most difficult contaminants to detect due to their varied shapes, low density, and tendency to blend into the product’s texture.

Metal fragments: Broken processing blades, wire bristles, or metal tags used in sorting can end up in seafood products, especially during high-speed cutting or deboning operations.

Glass pieces: Though less common, glass contamination may occur due to breakage from light fixtures, containers, or handling equipment in processing facilities.

Shell fragments: Shells from shrimp, crab, or mollusks may not be completely removed during peeling and processing, posing a hazard in products labeled as “shell-free.”

Hard plastics: Parts from broken conveyors, packaging tools, or utensils can chip off and fall into production lines.

Packaging-related contaminants: Materials like aluminum foil, film layers, or sealing clips can accidentally be introduced during final stages of packing, especially in automated lines.

Each of these foreign bodies poses a risk not only to consumer safety but also to operational compliance and brand trust. This is why many manufacturers are adopting advanced X-Ray inspection systems—capable of detecting both metallic and non-metallic contaminants—to prevent these risks from reaching consumers.

Impact of Undetected Contaminants

The presence of undetected foreign objects in seafood can have serious and far-reaching consequences:

Consumer safety concerns: Sharp or hard contaminants such as bones, metal fragments, or shell pieces can lead to choking, lacerations, or internal injury, putting consumer health at immediate risk. This can trigger legal action and damage the company’s reputation irreparably.

Product recalls and brand damage: Recalls due to contamination are costly and damaging. Not only do they involve logistical challenges and financial losses, but they also erode customer confidence. In the seafood sector, where freshness and purity are key selling points, even a single incident can cause long-term brand damage.

Regulatory non-compliance: Food safety authorities across the globe—including the FDA, EU regulators, and others—enforce strict standards regarding foreign matter in food. Failure to comply can lead to fines, factory shutdowns, or bans on exports. For seafood exporters, especially, maintaining a flawless quality record is essential for market access and certification.

With these risks in mind, it’s clear why investing in advanced X-Ray inspection machines is becoming an industry standard. These systems not only help meet regulatory requirements but also play a crucial role in preserving consumer trust and ensuring sustainable business growth in the highly competitive seafood market.

How X-Ray Inspection Technology Works

In the ever-demanding world of seafood quality control, detecting and eliminating foreign contaminants is critical for maintaining food quality and ensuring consumer safety. Traditional detection technologies such as metal detectors or visual inspection often fall short, especially when dealing with non-metallic contaminants or complex product shapes. This is where the X-Ray inspection system provides a smarter, more reliable solution.

Principles of X-Ray Imaging

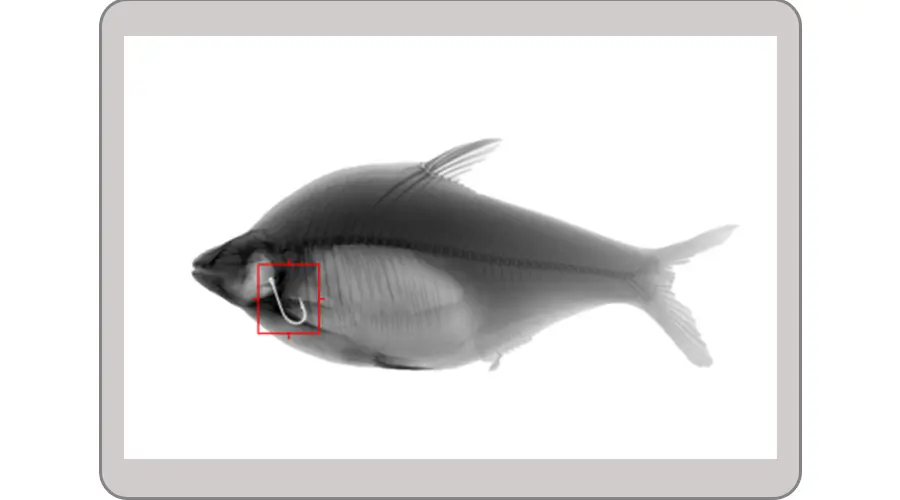

At its core, X-Ray inspection technology operates based on density differentiation. When seafood products pass through an X-Ray inspection machine, the system emits low-level X-rays that penetrate the product and capture detailed grayscale images based on varying densities within the item.

Density-based detection: Foreign bodies such as bones, shells, metals, or plastics often have a different density than the seafood itself. These differences appear as contrasts on the X-ray image, allowing the system to identify even minute contaminants that are visually invisible or embedded deep inside the product.

Dual-energy vs. single-energy systems: Advanced X-Ray inspection systems now incorporate dual-energy technology, which uses two different energy levels to differentiate materials more accurately. This is especially useful in seafood processing, where low-density bones or shells can be hard to distinguish from the flesh of the product. Dual-energy systems provide enhanced contrast, enabling better discrimination between safe and hazardous materials—something single-energy systems may struggle with.

Whether the product is fish fillet, shrimp, or crab meat, this technology ensures high-precision inspection without compromising speed or production efficiency.

Advantages Over Traditional Methods

Compared to conventional detection methods like metal detectors, X-Ray inspection machines offer several significant advantages, particularly for seafood applications:

Detection of hidden or embedded contaminants: Unlike metal detectors, which are limited to conductive materials, X-ray systems can detect both metallic and non-metallic contaminants—including bones, glass, hard plastics, and shell fragments—even when they are embedded inside thick or opaque products.

Compatibility with complex seafood formats: Seafood often comes in irregular shapes and textures, and may be packaged in foil or vacuum-sealed film. Traditional detectors often struggle in such scenarios. X-ray systems, however, excel at maintaining inspection accuracy even with sealed, frozen, or irregularly shaped seafood products.

Non-destructive testing: One of the greatest benefits is that X-ray inspection is non-invasive and non-destructive. It maintains the integrity and appearance of the product while ensuring safety, making it ideal for high-value seafood items that must meet both quality and aesthetic standards.

As regulatory standards rise and consumer expectations evolve, the adoption of smart X-Ray inspection machines has become an integral part of modern food quality assurance in the seafood industry. Not only do these systems help prevent contamination-related incidents, but they also support manufacturers in building trust and compliance in global markets.

Application of X-Ray Systems in Seafood Processing Lines

In modern seafood manufacturing, maintaining product integrity while ensuring safety and compliance is non-negotiable. X-Ray inspection systems have emerged as a vital tool across seafood processing lines, offering precise detection of foreign bodies without interrupting production. Powered by AI algorithms and deep learning, these advanced machines support manufacturers in enhancing seafood quality control from filleting to final packaging.

Bone Detection in Fillets

One of the most persistent challenges in seafood processing is detecting fine pin bones—especially in high-value species like salmon, mackerel, or trout. These bones are often small, low in density, and embedded within the flesh, making them difficult to detect using traditional inspection tools.

Today’s advanced X-Ray inspection machines incorporate deep learning algorithms and intelligent image recognition to locate even the most elusive bones. These systems analyze large datasets of fish images and continuously improve detection accuracy by learning the typical shape, size, and density patterns of pin bones. With this approach:

Bone detection becomes more accurate over time.

False positives are significantly reduced.

The system can adapt to different species and fillet thicknesses automatically.

As a result, processors can deliver safer, bone-free fillets to consumers without compromising food quality or yield.

Contaminant Detection in Processed and Packaged Seafood

Seafood isn’t just sold raw. The market demand for value-added and processed seafood products—such as shrimp, fish balls, scallops, and squid rings—is rapidly increasing. These items often go through multiple processing stages and are packed in trays, vacuum bags, or metalized films. Ensuring contaminant-free products at this stage requires high-performance inspection solutions.

X-Ray inspection systems excel in these scenarios by identifying a wide range of foreign materials, including: glass fragments, metal clips or wires, shell piecer, rigid plastics

Thanks to advanced tuning and dual-energy X-ray technology, these machines can distinguish between safe components and harmful contaminants—even when products are high in moisture or salt content, which often interfere with metal detectors. Moreover, inspection remains accurate even when products are frozen, tightly packed, or placed in overlapping positions.

These intelligent detection systems not only reduce the risk of consumer complaints and product recalls but also help seafood manufacturers stay compliant with international food safety standards such as HACCP, IFS, and BRC.

Benefits of Integrating X-Ray Inspection

As global demand for premium, contaminant-free seafood continues to grow, more manufacturers are turning to X-Ray inspection systems to meet both safety expectations and operational efficiency goals. By integrating these systems into seafood processing lines, producers can elevate their seafood quality control strategy to a whole new level.

Enhanced Product Quality and Safety

The primary benefit of deploying X-Ray inspection machines is a substantial improvement in food quality and product safety. These systems help detect and eliminate hazardous foreign objects such as bones, metal fragments, glass, and shells that are often missed by manual inspection or conventional metal detectors.

This leads to:

Fewer customer complaints: With fewer contaminants slipping through, manufacturers experience significantly reduced consumer dissatisfaction and fewer returns.

Stronger brand reputation and trust: Delivering consistently safe products fosters long-term customer loyalty.

Compliance with international standards: Whether exporting to the European Union, United States, Japan, or other regions with strict food import requirements, X-Ray inspection systems support regulatory compliance by providing reliable detection and traceability.

These improvements in quality assurance are especially vital for high-risk, high-value seafood products where safety concerns can have serious legal and financial consequences.

Improved Production Efficiency

Beyond safety, X-Ray inspection systems also drive measurable gains in production efficiency. Modern systems are built to integrate seamlessly with fast-moving seafood lines and can operate continuously with minimal human intervention.

Key operational benefits include:

Real-time rejection of defective products: Contaminated items are automatically removed from the line without halting production, reducing downtime and increasing throughput.

Minimal false rejections: Thanks to advanced algorithms, the system can distinguish between real contaminants and benign density changes, reducing unnecessary waste.

Process optimization through data analytics: Many systems come with integrated reporting tools that collect inspection data in real time. Manufacturers can analyze this data to pinpoint where contaminants enter the process, identify recurring issues, and refine upstream operations.

The result is a leaner, smarter production environment that balances food quality with cost control—key to staying competitive in today’s seafood market.

Easyweigh & Foodman’s Role in Seafood X-Ray Innovation

In the ever-evolving world of seafood quality control, manufacturers need advanced, reliable, and application-specific solutions to stay ahead of growing food safety regulations and rising consumer expectations. This is where Easyweigh and its sub-brand Foodman have emerged as industry leaders—pushing the boundaries of X-Ray inspection systems specifically designed for the unique challenges of seafood processing.

Purpose-Built Systems for Seafood

Unlike one-size-fits-all equipment, Foodman X-Ray inspection machines are engineered with a clear understanding of the seafood industry’s demands. From detecting fine pin bones in fillets to identifying foreign materials like shells, metal clips, or plastic in processed products, each system is tailored to detect contaminants common in seafood formats such as salmon fillets, shrimp, scallops, squid rings, and fish balls.

With the help of advanced dual-energy imaging and AI-powered algorithms, these systems offer:

Precise detection of low-density contaminants such as bones or shells

Reliable performance in high-moisture, high-salt, or irregularly shaped productsMinimal false rejections and enhanced efficiency on fast-moving production lines

This purpose-driven approach ensures that X-Ray inspection systems not only deliver high detection accuracy but also align with the specific food safety priorities of seafood processors worldwide.

IP66-Rated Waterproof Designs for Wet Processing Environments

Seafood production environments are often humid, wet, and harsh—conditions that can quickly degrade standard equipment. Easyweigh and Foodman address this with IP66-rated waterproof and dustproof designs, offering robust protection for the internal components of the X-Ray inspection machines.

Key design features include:

Fully sealed inspection tunnels

Separation of light source and control cabinets to prevent moisture damage

Anti-condensation cooling systems to ensure stable performance

Easy-to-clean surfaces that meet hygiene standards in seafood processing

By combining high-performance detection with rugged construction, Easyweigh and Foodman systems provide dependable operation in even the most demanding production environments—keeping your food quality standards intact without compromising uptime or durability.

Conclusion

As global demand for safe, high-quality seafood continues to rise, producers face increasing pressure to meet rigorous safety standards while maintaining operational efficiency. In this context, X-Ray inspection systems have become a vital tool for modern seafood quality control—offering unmatched accuracy, reliability, and adaptability.

Unlike traditional inspection methods, X-Ray inspection machines provide non-destructive, real-time detection of contaminants such as bones, shells, metal fragments, and plastic—even within sealed or frozen products. With the integration of dual-energy imaging, AI algorithms, and intelligent rejection systems, seafood processors can ensure food safety without slowing down production.

Looking ahead, the future of seafood safety is smart, automated, and highly data-driven. Innovations from leaders like Easyweigh and Foodman are paving the way for intelligent inspection solutions that not only detect foreign materials but also contribute to process optimization, regulatory compliance, and brand protection.

Investing in advanced X-Ray inspection technology is no longer optional—it’s a strategic move for seafood manufacturers committed to delivering the highest standards of quality, consistency, and consumer trust.

FAQ

Q1: Why is traditional metal detection not enough for seafood inspection?

A: Traditional metal detectors can only identify metallic contaminants. However, seafood products may contain non-metallic hazards like bones, shells, glass, or hard plastic—especially in processed or value-added forms. X-Ray inspection systems detect contaminants based on density differences, enabling them to identify both metallic and non-metallic foreign bodies, even in sealed or frozen packaging.

Q2: What makes bones and shells difficult to detect in seafood?

A: Fish bones and shell fragments are typically small, low-density, and irregularly shaped. They often blend into the product’s texture, making them hard to detect using visual inspection or metal detectors. X-Ray systems, especially those with dual-energy imaging and AI algorithms, can differentiate these fine structures based on density and shape, achieving much higher detection accuracy.

Q3: Can X-Ray inspection systems operate effectively in wet and humid seafood processing environments?

A: Yes. X-Ray systems from companies like Easyweigh and Foodman are designed with IP66-rated waterproof protection, anti-condensation cooling, and hygienic construction to ensure reliable performance in wet, high-humidity, or salt-rich environments commonly found in seafood factories.