Introduction

In industries where safety, quality, and compliance are non-negotiable—such as food processing, pharmaceuticals, and high-precision manufacturing—X-Ray inspection plays a vital role in detecting foreign bodies and product defects. The performance of an X-Ray inspection system, particularly its sensitivity, directly influences its ability to detect even the smallest contaminants, such as bone fragments, glass shards, or tiny pieces of metal. Whether it’s a standalone X-Ray inspection machine on a production line or a fully integrated X-Ray inspection equipment solution in a large-scale facility, the system’ s sensitivity is the key to ensuring product safety, reducing recalls, and maintaining brand trust.

But what exactly does sensitivity mean in the context of X-Ray inspection? In simple terms, it refers to the system’ s ability to detect the smallest and least dense foreign materials within a product—often measured in millimeters or by mass. In practical application, a highly sensitive system can detect contaminants that would go unnoticed by traditional inspection methods, especially in challenging environments like dense packaging or high-speed lines.

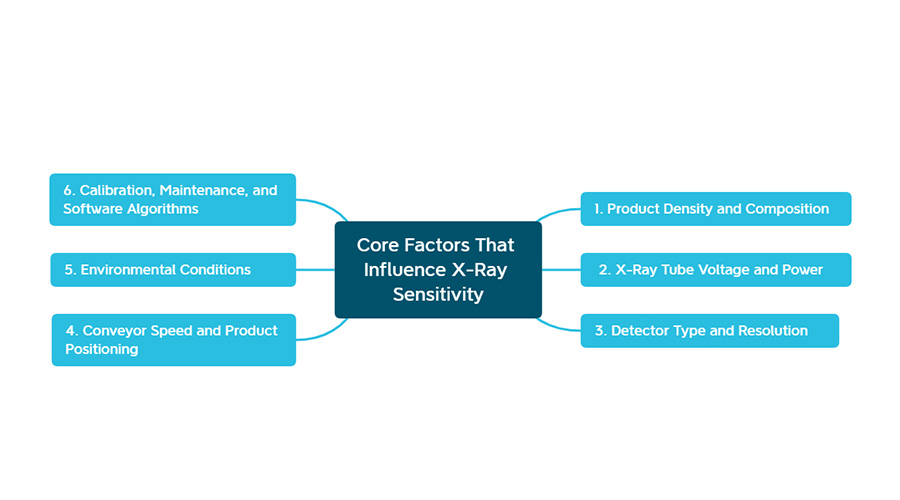

Understanding and optimizing sensitivity is critical because the smallest overlooked contaminant can lead to significant consequences, from regulatory fines to consumer health risks. This blog will explore the core factors that impact sensitivity in X-Ray inspection systems, including detector resolution, product type, energy levels, and image processing algorithms. By optimizing these factors, manufacturers can significantly enhance detection accuracy, improve operational efficiency, and stay ahead in an increasingly competitive and regulated marketplace.

Understanding X-Ray System Sensitivity

What Does “sensitivity” Mean in X-Ray Inspection?

In the realm of X-Ray inspection, sensitivity refers to the system’ s ability to detect the smallest or lowest-density foreign materials within a product. This includes contaminants such as bone fragments, glass shards, rubber, plastic, and even tiny metal particles. The higher the sensitivity, the smaller and less dense the object the X-Ray inspection machine can identify with accuracy.

Technically, sensitivity is often expressed in terms of the minimum detectable size, measured in millimeters, and the material type. For example, a high-end X-Ray inspection system might be able to detect stainless steel contaminants as small as 0.3 mm or thin bone fragments that are nearly invisible to the naked eye. These capabilities are critical in applications like meat processing or dairy production, where the density contrast between the product and the contaminant can be very subtle.

Why Sensitivity Matters in Quality Control

The sensitivity of your X-Ray inspection equipment has a direct impact on product quality, consumer safety, and regulatory compliance. In the food industry, for instance, failing to detect a single piece of metal or bone can lead to product recalls, legal liability, or worse—serious injury to a consumer. In pharmaceuticals, undetected contaminants can compromise product purity and violate stringent GMP regulations.

Moreover, sensitivity also affects the balance between false positives and false negatives. A system with low sensitivity may fail to detect real contaminants (false negatives), while an overly sensitive system may mistakenly reject safe products (false positives). Both scenarios lead to increased operational costs—either through wasted product or through undetected safety hazards.

Optimizing the sensitivity of your X-Ray inspection system means you can reliably detect harmful foreign objects while minimizing unnecessary waste, protecting both your consumers and your bottom line.

Core Factors That Influence X-Ray Sensitivity

Achieving high sensitivity in an X-Ray inspection system is not just about having the most advanced equipment—it also depends on how well the system is optimized for the specific inspection environment. Below are the key factors that directly affect the sensitivity of any X-Ray inspection machine.

Product Density and Composition

The density and composition of the inspected product play a crucial role in detection performance. Dense or multi-layered products (such as blocks of cheese, meat with bones, or granola bars with nuts) can make it harder for X-Ray inspection equipment to detect low-density foreign materials like plastic or rubber. A well-calibrated system must account for these material characteristics to avoid blind spots.

X-Ray Tube Voltage and Power

The X-Ray tube is the heart of the X-Ray inspection system. Its voltage and power levels determine the penetration ability of the X-ray beam. Higher voltages are better for dense or thick products, while lower voltages provide better contrast for detecting low-density materials in lightweight items. The balance between power and resolution is critical for maintaining sensitivity without sacrificing accuracy or image clarity.

Detector Type and Resolution

The type and resolution of the X-Ray detector significantly influence the system’s ability to capture subtle differences in material density. High-resolution detectors enable the X-Ray inspection machine to identify minute defects or foreign bodies by delivering more detailed imaging. Advanced detectors also enhance grayscale depth, improving the system’s ability to distinguish between product texture and actual contaminants.

Conveyor Speed and Product Positioning

The speed at which products move through the X-Ray inspection equipment affects the exposure time and image quality. Faster conveyor speeds can reduce detection sensitivity if not properly compensated by the system. Additionally, the position and orientation of the product during scanning influence the detectability of certain contaminants. Consistent product presentation enhances inspection accuracy.

Environmental Conditions

External conditions such as temperature, humidity, and vibration can impact the performance of X-Ray inspection systems. For example, extreme humidity may affect electronic components or cause condensation, which can interfere with image quality. Modern systems often include environmental controls or robust housing to maintain stable operation in challenging conditions.

Calibration, Maintenance, and Software Algorithms

Regular calibration and maintenance are essential to sustain high sensitivity. Dust buildup, worn components, or misaligned parts can degrade performance over time. Equally important are the image processing algorithms—today’ s leading X-Ray inspection equipment incorporates AI-based software that can learn and improve detection capability over time. Algorithms that perform material discrimination, edge detection, and anomaly recognition are critical for reducing false results and improving overall sensitivity.

Conclusion

Sensitivity is one of the most crucial metrics in any X-Ray inspection system, directly influencing the accuracy of detection and the overall safety of the production process. It determines how effectively an X-Ray inspection machine can identify foreign bodies—especially those that are small, low-density, or irregularly shaped.

This capability is not determined by a single element alone. It results from the interaction between product properties, machine configuration, and operational practices. Factors like product density, conveyor speed, software algorithms, and regular calibration all work together to define how sensitive your X-Ray inspection equipment truly is.

By gaining a deep understanding of these variables and continuously optimizing them, manufacturers can significantly improve their quality control processes. A well-calibrated, high-sensitivity X-Ray inspection line not only enhances food and product safety but also protects brand reputation, reduces waste, and ensures compliance with industry standards.

Investing in sensitivity optimization is not just about better detection—it’s about smarter production and long-term peace of mind.

FAQ

Q1: How does product density affect X-Ray sensitivity?

A: Denser or multi-layered products can obscure low-density contaminants, making them harder to detect. Proper calibration and optimized settings are necessary to ensure consistent detection across various product types.

Q2: Can X-Ray sensitivity be adjusted based on different products?

A: Yes. Modern X-Ray systems allow customization of settings such as voltage, power, inspection mode, and algorithm tuning to suit different product types, densities, and packaging, improving detection performance for each use case.

Q3: How does conveyor speed influence sensitivity?

A: Faster conveyor speeds reduce the exposure time of the product to the X-Ray beam, which can degrade image quality and lower detection sensitivity. Systems must be calibrated to maintain sensitivity at different line speeds.