What is Image Processing in the Context of X-Ray Inspection?

In industrial environments, X-Ray inspection has evolved into a sophisticated and reliable method for detecting internal defects, contaminants, and irregularities that are otherwise invisible to the naked eye. At the core of every X-Ray inspection system lies image processing—a critical technology that transforms raw X-ray signals into meaningful visual data for real-time decision-making.

Definition of Image Processing in Industrial Settings

Image processing, in the context of X-Ray inspection equipment, refers to the computational techniques used to capture, enhance, analyze, and interpret X-ray images during production. Unlike traditional visual inspection methods, image processing allows X-Ray inspection machines to automatically recognize foreign objects, detect product inconsistencies, and validate structural integrity based on pixel-level data. It forms the backbone of smart quality control, enabling manufacturers to automate inspections, reduce human error, and comply with strict industry regulations.

How Image Data is Captured, Processed, and Analyzed in Real-Time

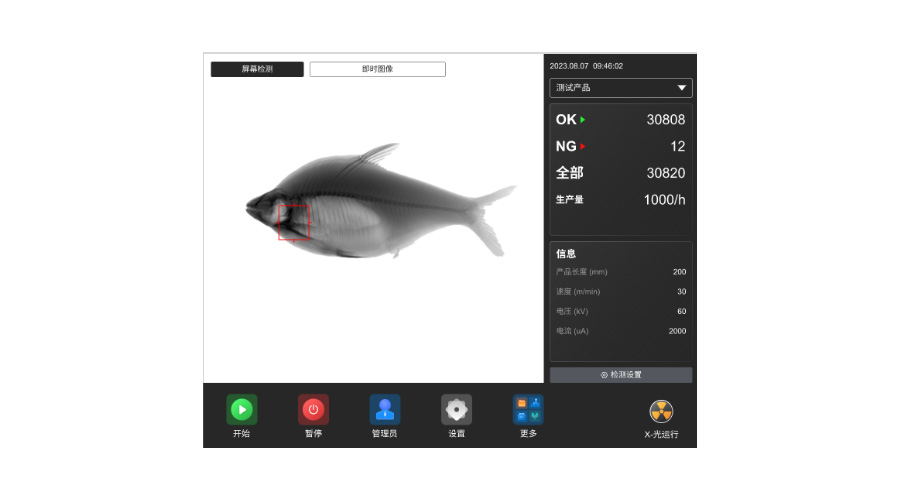

In a typical X-Ray inspection system, the process begins when a product passes through the X-ray beam. The X-Ray inspection equipment captures raw image data using high-resolution detectors. This data is then instantly processed by embedded software that applies noise reduction, contrast enhancement, and material differentiation algorithms. Real-time analysis enables the system to make immediate decisions—such as flagging contaminants, missing components, or underfilled packaging. By leveraging advanced image processing, modern X-Ray inspection machines not only increase accuracy but also accelerate production without compromising safety or quality.

Key Functions Enabled by Image Processing

Modern X-Ray inspection systems are no longer just tools for visibility—they are intelligent inspection solutions capable of performing advanced quality control tasks that were once only possible through manual processes. Central to this evolution is image processing technology, which enables X-Ray inspection machines to interpret captured images, detect anomalies, and make real-time decisions based on product characteristics. From identifying contaminants to verifying seal integrity, these systems are redefining how manufacturers ensure product quality and safety.

Foreign Object Detection: Identifying Contaminants Like Metal, Glass, Bone, and Plastic

One of the core strengths of an X-Ray inspection system lies in its ability to detect foreign materials embedded within products or packaging—objects that are often invisible to the naked eye or conventional vision systems. Using sophisticated image analysis algorithms, the X-Ray inspection equipment scans the internal structure of products to identify a wide range of contaminants such as:

Ferrous and non-ferrous metals

Stainless steel fragments

Broken glass pieces

Natural contaminants like bone shards

Dense plastics and rubbers

These contaminants can be detected even when buried within dense or multi-layered packaging. For example, in ready-to-eat meals or packaged meats, X-Ray inspection machines are able to distinguish between the expected product material and foreign bodies, flagging potential risks instantly. This capability helps manufacturers prevent product recalls, comply with international food safety standards (such as HACCP, BRC, and IFS), and protect brand reputation.

Dimensional Analysis: Measuring Shape, Size, and Volume of Products

Beyond contaminant detection, X-Ray inspection equipment plays a vital role in verifying product geometry. Accurate dimensional analysis ensures each item meets strict manufacturing specifications and customer expectations. By leveraging high-resolution detectors and real-time image processing, the system can:

Measure the length, width, and height of each product

Calculate product volume

Compare individual items against a reference model or tolerance range

Detect shape irregularities or deformation caused by incorrect processing or handling

This function is especially useful in sectors like bakery, dairy, or confectionery, where even minor inconsistencies in size or shape can affect consumer satisfaction and packaging efficiency. Integrating dimensional analysis into X-Ray inspection systems eliminates the need for additional inline measurement tools, streamlining production lines and reducing equipment costs.

Completeness Checks: Verifying Presence of Components

X-Ray inspection machines are increasingly used for completeness checks in multi-component products, such as snack packs, pharmaceutical blister packs, or boxed goods with several layers. Image processing allows the system to:

Confirm the presence and position of each item in a package

Detect missing or misaligned components

Ensure uniformity in count and layout

Identify damaged or fragmented items

For example, a pharmaceutical company can use an X-Ray inspection system to verify that every cavity in a blister pack contains a pill and that no broken or misplaced tablets are present. Similarly, in the food industry, the machine can ensure that every compartment in a lunch box contains the correct ingredients in the proper portion. By automating this process, companies minimize human error and speed up packaging verification without sacrificing accuracy.

Seal & Fill Verification: Detecting Underfills, Broken Items, or Seal Integrity Issues

Ensuring the correct fill level and integrity of a product’s packaging is critical—not only for consumer trust but also for preventing spoilage, leakage, or contamination. With the help of image processing, X-Ray inspection systems can analyze the internal density and layout of a product to:

Detect underfilled or overfilled containers

Identify broken or fractured items within sealed packages

Evaluate seal integrity by detecting trapped product or air pockets

Monitor uniform fill distribution in items like yogurt cups, juice pouches, or sealed trays

Unlike conventional weight checks that only evaluate the total mass, X-Ray inspection machines assess the internal structure, allowing for pinpoint accuracy in detecting packaging issues. This is particularly beneficial for liquid, semi-solid, or granular products where distribution consistency directly impacts product quality and shelf life.

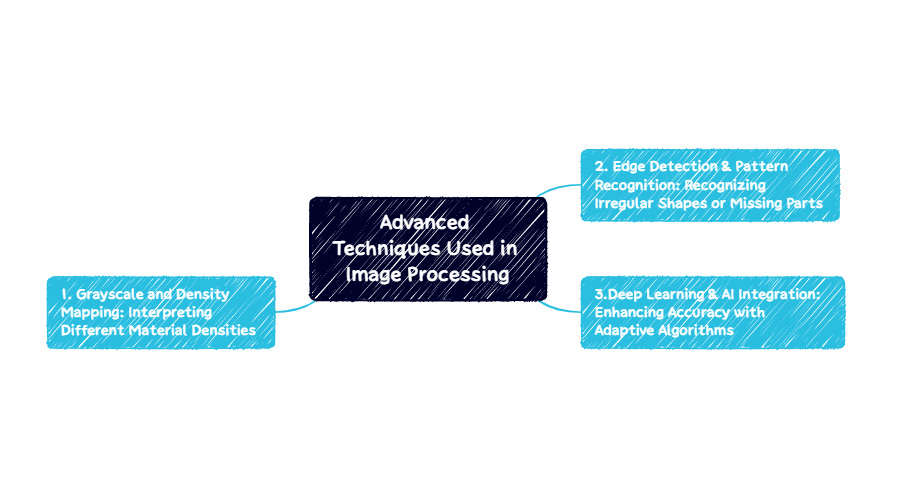

Advanced Techniques Used in Image Processing

Today’ s X-Ray inspection systems are equipped with more than just high-powered X-ray sources—they integrate sophisticated image processing techniques that turn raw image data into precise, meaningful insights. These advanced technologies enable X-Ray inspection machines to distinguish between normal and abnormal product features, identify material differences, and continuously adapt to complex inspection tasks. Here’s a look at three key techniques driving innovation in modern X-Ray inspection equipment:

Grayscale and Density Mapping: Interpreting Different Material Densities

One of the foundational tools in image processing for X-Ray inspection is grayscale and density mapping. Every material has a unique X-ray absorption rate based on its density and thickness. By converting the captured data into grayscale images, X-Ray inspection machines can:

Differentiate between high-density materials like metal or bone and low-density materials like soft tissue or plastic.

Visualize internal structures of a product with varying intensity levels.

Highlight hidden or embedded foreign objects that standard vision systems would miss.

For instance, in food processing lines, X-Ray inspection systems can use grayscale contrast to detect tiny bone fragments in fish fillets or plastic pieces in ground meat, which may be visually undetectable. This non-destructive inspection method ensures food safety and enhances compliance with international quality standards.

Edge Detection & Pattern Recognition: Recognizing Irregular Shapes or Missing Parts

Edge detection and pattern recognition are essential for structural analysis and product verification. Using advanced algorithms, X-Ray inspection equipment can:

Identify product boundaries, contours, and structural features.

Detect irregular shapes, missing segments, or incomplete assemblies.

Compare actual products against learned or programmed patterns in real time.

These techniques are especially valuable in industries like electronics and pharmaceuticals, where even the smallest misalignment or missing component can lead to critical product failure. For example, an X-Ray inspection machine on a pharmaceutical line can recognize whether a blister pack is missing a tablet or if an inserted object is misaligned—alerting operators before defective products reach the consumer.

Deep Learning & AI Integration: Enhancing Accuracy with Adaptive Algorithms

The integration of artificial intelligence (AI) and deep learning is revolutionizing the performance of modern X-Ray inspection systems. Unlike traditional rule-based algorithms, deep learning models can be trained using large datasets to recognize complex patterns and continuously improve over time. AI-powered X-Ray inspection machines can:

Learn from thousands of product images to improve defect detection accuracy.

Adapt to variations in product type, shape, or packaging material.

Reduce false positives and improve overall inspection efficiency.

Automatically update detection parameters based on new data.

In real-world applications, AI-enhanced X-Ray inspection equipment has proven especially effective in handling high-speed production lines, detecting previously unseen defect types, and minimizing downtime caused by manual recalibration. This level of intelligence significantly boosts operational efficiency and positions the system as a smart, future-ready solution for manufacturers.

Benefits of Image Processing in X-Ray Inspection Systems

Image processing lies at the heart of modern X-Ray inspection systems, transforming raw scan data into accurate, real-time insights that drive smarter quality control decisions. Whether in food, pharmaceutical, or manufacturing industries, the integration of advanced image processing into X-Ray inspection equipment has significantly elevated inspection precision, efficiency, and traceability. Below are the core benefits this technology brings to today’s X-Ray inspection machines:

Higher Detection Accuracy and Fewer False Positives

One of the most important advantages of advanced image processing is its ability to enhance detection accuracy while minimizing false alarms. Through intelligent filtering, contrast enhancement, and AI-powered classification, X-Ray inspection systems can:

Precisely identify foreign bodies—even those with low density or irregular shapes.

Distinguish between acceptable variations and real defects.

Reduce unnecessary product rejections, cutting costs and improving yield.

For industries with tight safety regulations—such as food and pharmaceuticals—this precision ensures that X-Ray inspection machines meet or exceed compliance standards without over-inspecting or rejecting safe products.

Improved Traceability and Documentation Through Image Records

Modern X-Ray inspection equipment doesn’t just detect defects—it also stores image records for every inspected product. These high-resolution image archives provide:

Visual documentation for quality audits and regulatory inspections.

A digital footprint that supports full product traceability.

Evidence for customer complaints or recalls, increasing accountability and transparency.

This traceability is particularly valuable in global supply chains, where product verification at every stage is critical. Having a built-in visual log helps manufacturers track product history and ensure continuous improvement.

Automation and Faster Throughput Without Compromising Quality

Thanks to high-speed image processing algorithms, X-Ray inspection machines can inspect thousands of products per hour—without sacrificing accuracy. Key benefits include:

Seamless integration into automated production lines.

Faster decision-making with fewer bottlenecks.

Labor savings through reduced need for manual checks.

As a result, manufacturers benefit from both higher productivity and more consistent quality assurance. This level of automation enables X-Ray inspection systems to keep pace with modern high-output operations, such as those in snack packaging, beverage bottling, or pharmaceutical filling lines.

Real-Time Decision-Making Capabilities

Advanced image processing allows X-Ray inspection systems to make smart, immediate decisions. By analyzing product data on the fly, these systems can:

Automatically remove defective products from the line.

Trigger alerts for process deviations.

Adapt inspection parameters dynamically based on real-time feedback.

This real-time response empowers manufacturers to act swiftly, minimize waste, and avoid downtime. In today’ s competitive markets, being able to respond instantly to quality issues is a significant operational advantage.

Industry Applications of X-Ray Inspection Systems

Modern X-Ray inspection systems powered by advanced image processing are transforming quality control across multiple industries. Whether it’s ensuring food safety, verifying pharmaceutical packaging, or detecting defects in electronics, these systems offer unmatched versatility and precision. Below are key applications by sector, demonstrating how X-Ray inspection equipment adapts to specific industry needs.

Food Industry: Detecting Contaminants, Broken Items, and Fill Level Accuracy

In the food industry, maintaining safety, consistency, and compliance is paramount. X-Ray inspection machines are widely used to:

Detect foreign bodies such as bone, glass, metal, or plastic—even in packaged or dense products.

Identify broken or missing items, such as fractured cookies or incomplete meatballs.

Verify fill levels to avoid underfilling or overfilling, ensuring fair product weight and regulatory compliance.

By integrating image processing with X-Ray inspection equipment, food manufacturers can eliminate safety risks and protect their brand reputation while optimizing production efficiency.

Pharmaceuticals: Blister Pack Integrity, Tablet Count, Vial Inspection

In pharmaceutical manufacturing, accuracy and traceability are critical. X-Ray inspection systems provide non-invasive inspection of packaged medicines, enabling:

Verification of blister pack integrity by checking each cavity for the correct product.

Accurate tablet counting within bottles or blister packs without opening the packaging.

Detection of damaged or missing vials, as well as verification of proper fill levels.

These applications help ensure product safety, reduce human error, and support compliance with strict regulatory requirements—making X-Ray inspection machines a cornerstone of pharmaceutical quality assurance.

Consumer Goods & Electronics: Internal Component Verification and Tamper Detection

In the consumer goods and electronics industries, internal structural integrity is vital but often invisible to the naked eye. X-Ray inspection equipment is used to:

Verify placement and completeness of internal components in electronic devices, toys, or mechanical assemblies.

Detect potential tampering, missing parts, or packaging defects in high-value consumer products.

Inspect solder joints, connectors, and internal circuitry for quality control and failure prevention.

This non-destructive testing capability allows manufacturers to maintain high standards and avoid costly product recalls, while also enhancing trust with end consumers.

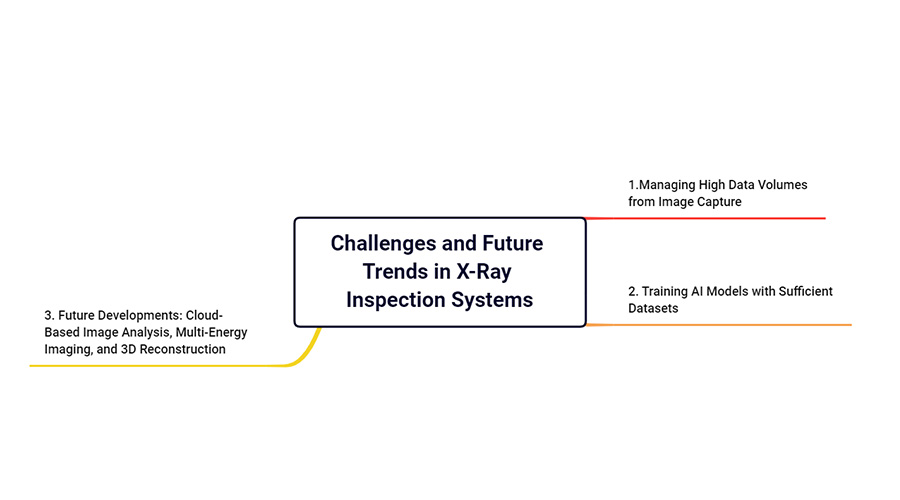

Challenges and Future Trends in X-Ray Inspection Systems

Modern X-Ray inspection systems have revolutionized quality control across multiple industries by leveraging advanced image processing and AI technologies. However, as these systems become more sophisticated, they also face significant challenges that manufacturers and operators must address to maximize efficiency and accuracy. Additionally, exciting future trends promise to push the capabilities of X-Ray inspection equipment to new heights. Let’s explore these challenges and what lies ahead.

Managing High Data Volumes from Image Capture

One of the primary challenges for any X-Ray inspection machine today is handling the enormous amount of image data generated during continuous inspection. High-resolution images are critical for detecting small defects and contaminants, but they also result in huge data streams. For instance, a fast-moving food production line can produce thousands of scans every hour, each requiring immediate analysis.

This immense data volume creates several technical hurdles:

Processing Speed: The internal processors of the X-Ray inspection system must handle real-time image analysis without causing production delays.

Storage Needs: Storing millions of images for traceability and regulatory compliance demands robust and scalable storage infrastructure.

Network Bandwidth: For systems using remote or cloud-based analysis, transferring large image files quickly and securely is crucial.

To address these challenges, manufacturers are integrating high-performance computing components and optimizing data compression algorithms within X-Ray inspection equipment. Edge computing—where data is processed near the source rather than being sent off-site—also helps reduce latency and bandwidth use.

Training AI Models with Sufficient Datasets

AI and deep learning are core to the enhanced accuracy of modern X-Ray inspection machines, enabling them to detect subtle defects and contaminants that traditional methods might miss. However, the success of AI depends heavily on the quality and quantity of training data.

Challenges in this area include:

Dataset Collection: Gathering comprehensive datasets that include a wide range of defects, foreign objects, and product variations is labor-intensive.

Data Labeling: Accurate annotation of images for supervised learning requires expertise and time, especially when identifying tiny or rare defects.

Model Adaptability: AI models need regular updates to stay effective as product designs, packaging materials, and manufacturing processes evolve.

To overcome these obstacles, many companies are investing in synthetic data generation and simulation tools to augment real-world datasets. Collaborative platforms that enable sharing anonymized defect data across industries are also emerging, accelerating AI training cycles. Continuous learning approaches allow X-Ray inspection systems to adapt dynamically on the production line, improving detection rates over time.

Future Developments: Cloud-Based Image Analysis, Multi-Energy Imaging, and 3D Reconstruction

Looking forward, several technological trends are set to transform the capabilities of X-Ray inspection equipment:

Cloud-Based Image Analysis: By leveraging cloud infrastructure, manufacturers can centralize data storage and apply powerful AI algorithms on large datasets collected from multiple production lines or facilities. This approach supports remote diagnostics, predictive maintenance, and global quality benchmarking, making X-Ray inspection systems more flexible and scalable.

Multi-Energy Imaging: Traditional X-Ray systems often use a single energy level, which limits their ability to differentiate materials with similar densities. Multi-energy or dual-energy imaging uses multiple energy spectra to better distinguish between materials like bone and plastic or different types of metals. This enhances contaminant detection and reduces false positives in complex products.

3D Reconstruction: Advances in image processing now allow X-Ray inspection machines to generate 3D models from multiple 2D scans. This volumetric insight helps detect defects hidden in layered or irregular-shaped items, such as pharmaceutical blister packs or multi-component electronics, that might be missed by flat imaging alone.

These innovations will make X-Ray inspection equipment not only more accurate but also more adaptive, allowing manufacturers to maintain the highest quality standards while improving production efficiency.

Conclusion

In summary, image processing plays a pivotal role in enhancing the overall effectiveness and value of modern X-Ray inspection systems. By enabling real-time analysis, precise defect detection, and comprehensive product evaluation, advanced image processing technology transforms standard X-Ray inspection machines into intelligent tools that deliver reliable quality control across industries.

Manufacturers who invest in upgrading their X-Ray inspection equipment to incorporate advanced image processing capabilities stand to gain significant benefits. These include higher detection accuracy, reduced false positives, faster throughput, and improved traceability—all crucial factors in meeting today’s stringent safety and compliance standards.

In today’s fast-paced production environment, relying on traditional inspection methods is no longer sufficient. Image processing is no longer a luxury but an essential component of any effective X-Ray inspection system. It ensures that products meet quality expectations, regulatory requirements, and consumer trust. For businesses looking to stay competitive and future-ready, embracing intelligent, image-driven X-Ray inspection machines is the clear path forward.

FAQ

Q1: What is image processing in the context of X-Ray inspection systems?

A: Image processing in X-Ray inspection refers to the computational techniques used to capture, enhance, analyze, and interpret X-Ray images. It transforms raw X-Ray data into meaningful visual information, allowing automated detection of foreign objects, defects, and product inconsistencies in real time.

Q2: How does image processing improve the accuracy of detecting contaminants in products?

A: Image processing uses advanced algorithms like grayscale mapping and AI to differentiate materials based on density and structure. This allows X-Ray systems to detect contaminants such as metal, glass, bone, or plastic even when they are hidden within complex or multi-layered packaging.

Q3: What are some key functions enabled by image processing in X-Ray inspection machines?

A: Key functions include foreign object detection, dimensional analysis (measuring size and volume), completeness checks (verifying presence of components), and seal & fill verification (detecting underfills or seal integrity issues).