Introduction

In today’ s fast-paced manufacturing environments, maintaining consistent product quality is more important than ever—especially in industries like food processing, pharmaceuticals, and packaging. Among the most reliable technologies for ensuring quality and safety is the X-Ray inspection process. Whether you’re dealing with bulk raw materials or individually packaged consumer goods, an advanced X-Ray inspection system plays a vital role in identifying foreign contaminants, detecting defects, and verifying product integrity.

However, like any form of automation, X-Ray inspection machines are not immune to challenges. One of the most common—and costly—issues is the occurrence of false positives, where the system incorrectly flags a good product as defective. These inaccurate detections not only reduce production efficiency but also increase operating costs and impact customer satisfaction.

To maximize the value of your X-Ray inspection equipment, it’s essential to understand why false positives happen and how to minimize them through better technology, smarter settings, and strategic process adjustments. In this blog, we’ll explore the root causes of false positives in X-Ray inspection and share proven techniques to reduce their impact on your operations.

What Are False Positives in X-Ray Inspection?

Definition: When the System Mistakenly Flags a Product as Contaminated or Defective

In the context of X-Ray inspection, a false positive refers to an error where the system incorrectly identifies a product as having a defect or containing a foreign object, even when it is perfectly safe and meets quality standards. This misidentification can happen due to irregular product shapes, overlapping packaging materials, or high-density ingredients that resemble contaminants to the system’s algorithm. Whether using a basic X-Ray inspection machine or a more advanced X-Ray inspection system, false positives are an unavoidable challenge without proper calibration and intelligent software.

Difference Between False Positives and False Negatives

Understanding the distinction between false positives and false negatives is crucial for any manufacturer relying on X-Ray inspection equipment for quality control. A false positive results in the rejection of a product that is actually acceptable, while a false negative allows a defective or contaminated product to pass through undetected. While false negatives are more dangerous in terms of food safety and compliance, false positives can be equally damaging to operational efficiency and profitability. Both outcomes undermine the reliability of the X-Ray inspection system, but false positives often receive less attention despite their cumulative cost.

Real-World Impact: Unnecessary Product Rejection, Line Stoppages, Increased Waste, and Re-Inspection Costs

The implications of false positives in X-Ray inspection go far beyond occasional product loss. Frequent false alarms can trigger:

Unnecessary product rejection, leading to avoidable waste of safe goods.

Production line stoppages, as flagged items often require manual verification.

Increased labor and re-inspection costs, especially when using high-speed X-Ray inspection machines.

Loss of productivity and reduced yield, impacting order fulfillment and supply chain consistency.

Over time, these issues significantly diminish the return on investment of your X-Ray inspection equipment, and can even erode customer trust due to inconsistent product availability.

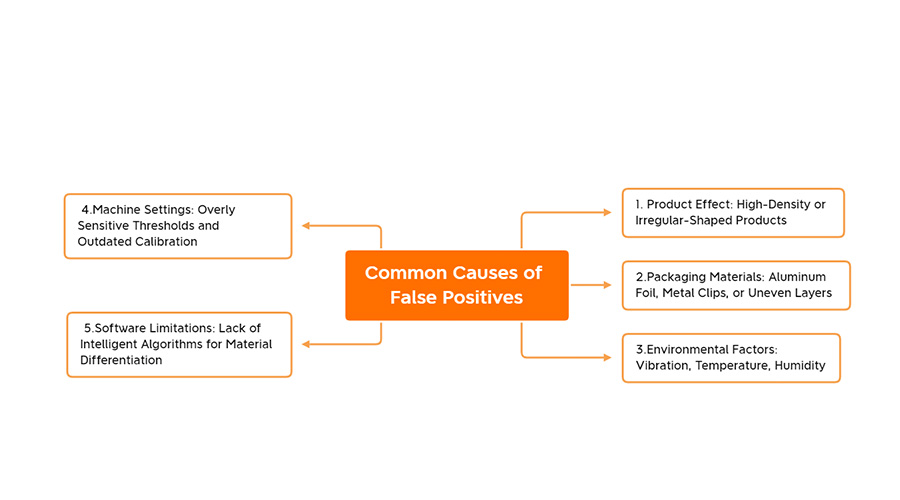

Common Causes of False Positives

Product Effect: High-Density or Irregular-Shaped Products

One of the most frequent sources of false positives in X-Ray inspection is the product effect. This occurs when high-density or irregular-shaped products—such as blocks of cheese, processed meat, or seafood—appear similar to foreign objects on the scan. These products can confuse even advanced X-Ray inspection systems, especially if they contain bone fragments or air pockets that create image anomalies. An effective X-Ray inspection machine must be able to differentiate between the natural density of the product and actual contaminants to reduce these errors.

Packaging Materials: Aluminum Foil, Metal Clips, or Uneven Layers

Many products are packaged in materials that interfere with X-Ray inspection equipment. Aluminum foil wraps, metal clips used in sausages, or layers of film and cardboard can all trigger false alarms. These materials reflect or absorb X-rays in ways that mimic foreign objects, particularly if the X-Ray inspection machine is not configured to account for them. Advanced systems with shielding functions and customizable detection zones can help mitigate these issues.

Environmental Factors: Vibration, Temperature, Humidity

The operating environment plays a critical role in the accuracy of an X-Ray inspection system. Excessive vibration on the production line can blur images and cause the system to misidentify defects. Similarly, high humidity or temperature fluctuations can affect the sensitivity and stability of the X-Ray inspection machine. High-quality X-Ray inspection equipment should be equipped with cooling systems, sealed detector enclosures, and vibration-resistant mounting to ensure optimal performance in varying conditions.

Machine Settings: Overly Sensitive Thresholds and Outdated Calibration

False positives often arise when the X-Ray inspection system is set to overly sensitive thresholds. While high sensitivity is important for detecting small contaminants, it can also increase the likelihood of misidentifying normal product features as defects. Additionally, outdated calibration can cause the system to drift from its intended detection parameters. Regular maintenance and calibration are essential for ensuring that X-Ray inspection machines remain both accurate and reliable.

Software Limitations: Lack of Intelligent Algorithms for Material Differentiation

Even the most advanced hardware can produce false positives if it is not paired with intelligent software. Many traditional X-Ray inspection systems struggle to differentiate between materials of similar density. Without machine learning algorithms or dual-energy analysis, the system may flag harmless product components as threats. Modern X-Ray inspection equipment now integrates AI-powered software that learns from thousands of images to improve detection accuracy and reduce false alarms.

How False Positives Affect Production

False positives—instances where an X-Ray inspection system mistakenly identifies a product as contaminated or defective—can have far-reaching consequences for manufacturers. While X-Ray inspection technology is designed to ensure product safety and quality, excessive false alarms can disrupt operations, increase costs, and damage trust in the inspection process.

Increased Operational Costs from Manual Re-Checks and Waste

Every false positive detected by an X-Ray inspection machine leads to an additional layer of manual work. Operators must physically remove the item from the production line, inspect it, and determine whether it is truly defective. These manual re-checks demand time and labor, which directly increases operational costs.

In addition, many manufacturers adopt a conservative approach to quality control: if the X-Ray inspection equipment flags a product, it is often discarded outright to avoid any potential risk. This approach, while cautious, leads to unnecessary waste—especially when high-value or perishable products are involved, such as premium seafood, meat, or pharmaceutical goods.

Over time, these operational inefficiencies accumulate, driving up production costs and cutting into profit margins.

Reduced Throughput and Efficiency

When a production line is frequently interrupted by false positives, the overall flow of goods slows down. In high-speed environments where thousands of products pass through an X-Ray inspection system every hour, even minor delays can cause a ripple effect, leading to decreased throughput and lower daily output.

Manufacturers often invest in X-Ray inspection machines to maintain high-speed, automated inspection with minimal downtime. However, when the system’s detection sensitivity is poorly configured or not adapted to the product type, it may generate frequent false alarms that compromise this efficiency. This results in more frequent stoppages and reduced productivity—counteracting the very purpose of installing X-Ray inspection equipment in the first place.

False Alarms Lead to Reduced Trust in the System Among Operators

In a production setting, human-machine interaction is critical. Operators rely on the feedback provided by X-Ray inspection systems to make decisions quickly and accurately. But when the system repeatedly flags clean or acceptable products as defective, it can erode confidence among staff.

Operators may begin to question the accuracy of the X-Ray inspection machine and start ignoring alerts or conducting inspections with less urgency. This mindset can lead to real contaminants or defects being overlooked, thereby increasing the risk of unsafe products reaching the consumer.

Trust in X-Ray inspection equipment is essential not only for efficient workflow but also for maintaining high safety standards and regulatory compliance.

Potential Product Shortage if Large Batches Are Falsely Rejected

In some cases, false positives don’t just affect individual items—they can result in entire product batches being held, quarantined, or scrapped. This scenario is especially damaging in industries with tight delivery timelines, such as frozen food, pharmaceuticals, or fresh produce, where shelf life is limited.

When an X-Ray inspection system flags multiple items from a single lot, manufacturers may be forced to stop production and re-inspect or discard large volumes of product. This can cause significant supply chain disruptions, delay orders, and even result in contract penalties or lost customers due to product shortages.

Such incidents highlight the importance of minimizing false positives while ensuring the X-Ray inspection machine continues to meet strict quality control standards.

Techniques to Reduce False Positives

Reducing false positives in X-Ray inspection systems is critical for maintaining operational efficiency and product quality. Fortunately, a combination of technological advancements and best practices can help manufacturers minimize these errors. Below are several effective techniques to reduce false alarms from your X-Ray inspection machines and ensure your X-Ray inspection equipment performs at its best.

Advanced Image Processing Algorithms

Modern X-Ray inspection machines benefit significantly from powerful image processing technologies. One such innovation is the integration of deep learning and AI-based material classification, such as the Foodman Intelligent Algorithm Platform (FIAP). This advanced platform leverages a large volume of image data to differentiate between real contaminants and benign product features, improving detection accuracy and drastically reducing false positives.

Additionally, dual-energy X-Ray inspection technology allows the system to analyze materials based on their absorption at two energy levels. This makes it easier to distinguish between organic substances (like meat or cheese) and inorganic contaminants (like glass, metal, or stone). As a result, the system can accurately detect real threats while ignoring harmless product variations.

Customizable Detection Settings

Every product has unique characteristics, and X-Ray inspection equipment must be tuned accordingly. Manufacturers can adjust detection sensitivity based on the specific product type and packaging to prevent the system from misidentifying normal density variations as foreign objects.

Many X-Ray inspection systems also allow for shielding zones—areas the system intentionally ignores during inspection. For example, products packaged with aluminum foil, metal clips, or desiccants can be programmed into the system’s detection logic to avoid unnecessary false alerts.

This flexibility is especially important in complex or multi-component products where uniform inspection is not always possible.

Regular Calibration and Maintenance

Like all precision instruments, X-Ray inspection machines require scheduled calibration and preventive maintenance to function accurately. Over time, factors such as mechanical wear, electronic drift, and dirt buildup can distort the imaging quality, leading to false positives.

Regularly calibrating your X-Ray inspection system ensures the detection thresholds remain accurate. It’s also vital to inspect and clean the detectors, conveyor belts, and shielding curtains—any component that might interfere with image clarity or object recognition.

Proper maintenance not only extends the lifespan of the X-Ray inspection equipment but also helps keep detection performance consistent and reliable.

Product Profiling and Learning

An effective way to minimize false positives is through product profiling, where the X-Ray inspection system is trained on a specific product’s standard appearance. This profile includes typical density, shape, and internal structure, allowing the system to recognize what “normal” looks like.

More advanced X-Ray inspection machines feature adaptive learning algorithms that improve over time. As the system processes more examples of a product, it becomes better at filtering out irrelevant variations and focusing only on genuine anomalies. This learning capability is especially beneficial in food manufacturing, where natural variation is common.

Operator Training

Even with the best X-Ray inspection equipment, human expertise remains essential. Skilled operators play a crucial role in minimizing false positives by correctly interpreting system feedback and making appropriate adjustments to detection settings.

Proper training ensures that personnel understand the system’s sensitivity parameters, know when to recalibrate or apply shielding zones, and can confidently respond to alerts without compromising safety or efficiency. When operators trust the system and know how to optimize its use, the overall accuracy of X-Ray inspection improves.

Choosing the Right X-Ray System to Minimize False Positives

Selecting the appropriate X-Ray inspection system is one of the most effective ways to reduce false positives and enhance quality control. Not all X-Ray inspection machines are created equal—some are tailored for specific applications and product types. Making an informed choice can significantly impact detection accuracy, operational efficiency, and long-term cost savings.

Importance of Selecting a System Designed for Your Specific Application

A key step in minimizing false positives is investing in X-Ray inspection equipment that’s engineered for your industry and product characteristics. For example, the inspection requirements for dense or irregular-shaped products like cheese, seafood, or meat differ greatly from those for bakery items or pharmaceuticals.

An X-Ray inspection machine that isn’t suited to your application may overreact to harmless product features or miss critical contaminants. Choosing the right system ensures that it can handle variations in density, shape, packaging material, and moisture content, all of which are common causes of false alerts.

In sectors like food processing, pharmaceutical manufacturing, and packaging, a tailored solution is not just a luxury—it’s a necessity for accurate, efficient, and safe inspection.

Features to Look for

When evaluating X-Ray inspection systems, it’s important to consider key features that help reduce false positives:

Dual-Energy Detection: This technology allows the X-Ray inspection machine to differentiate between materials of varying densities—such as organic versus inorganic substances. It greatly improves accuracy in identifying real contaminants while ignoring benign product attributes.

Adaptive Algorithms: Intelligent systems equipped with machine learning or AI-driven algorithms, like the FIAP (Foodman Intelligent Algorithm Platform), can learn the characteristics of each product over time. These algorithms become better at distinguishing between contaminants and acceptable product variations, reducing unnecessary rejections.

High-Resolution TDI Detectors: Advanced X-Ray inspection equipment that uses Time Delay Integration (TDI) detectors captures sharper images with better contrast, enabling more precise detection. High-resolution imaging reduces the likelihood of misinterpreting minor variations as contaminants.

Shielding Customization: The ability to define shielding zones within the detection area—such as ignoring metal clips, desiccants, or aluminum film packaging—helps eliminate predictable false positives without compromising safety. This is particularly valuable for pre-packaged or multi-layered products.

Investing in X-Ray inspection machines with these capabilities ensures not only fewer false alarms but also a more efficient and confident production process.

Conclusion

Reducing false positives in X-Ray inspection is not just a technical challenge—it’s a vital component of maintaining production efficiency, minimizing costs, and ensuring customer satisfaction. Understanding what causes false positives, how they affect your operations, and how to effectively address them can make a significant difference in your inspection outcomes.

Modern X-Ray inspection systems offer powerful features—from dual-energy technology to adaptive algorithms—that significantly reduce false triggers. However, technology alone isn’t enough. A truly effective solution combines advanced X-Ray inspection equipment, skilled operator management, and a commitment to regular maintenance and calibration. This holistic approach ensures the system consistently performs at its best, accurately distinguishing between actual contaminants and acceptable product variations.

Finally, choosing the right partner matters. Work with experienced X-Ray inspection machine providers who not only offer intelligent, adaptable systems but also deliver strong after-sales support, including operator training, system updates, and remote diagnostics. These partnerships ensure that your X-Ray inspection system evolves with your needs and continues to meet the highest standards of quality control.

With the right technology and support, you can minimize false positives and maximize the reliability and value of your X-Ray inspection process.

FAQ

Q1: What product characteristics often cause false positives?

A: High-density or irregular-shaped products, such as cheese, processed meat, or seafood, can mimic contaminants in X-Ray images, causing the system to flag them incorrectly.

Q2: How do packaging materials contribute to false positives?

A: Materials like aluminum foil, metal clips, or multilayered films can interfere with X-Ray signals, sometimes resembling foreign objects and triggering false alarms.

Q3: Can environmental factors affect false positive rates?

A: Yes, vibration, temperature changes, and humidity can affect image clarity and system sensitivity, increasing the chances of false positives.