Introduction

The Growing Importance of Sustainability and Safety in Modern Manufacturing

As environmental awareness and consumer expectations continue to rise, modern manufacturing is under increasing pressure to balance sustainability with uncompromising safety standards. Today’s manufacturers must not only ensure the safety and quality of their products but also adopt eco-conscious practices that reduce waste, conserve resources, and minimize their environmental footprint.

X-Ray Inspection as a Key Technology for Product Safety and Quality

To meet these dual demands, many manufacturers are turning to X-Ray inspection as a core part of their quality control strategies. A modern X-Ray inspection system is designed to detect foreign bodies such as metal, bone, glass, and plastic, ensuring that only safe, high-quality products reach the consumer. Whether in the form of a standalone X-Ray inspection machine or as part of integrated X-Ray inspection equipment, this technology plays a vital role in identifying contaminants that traditional methods often miss.

Supporting Eco-Friendly Manufacturing Through X-Ray Inspection

Beyond ensuring safety, X-Ray inspection equipment also contributes directly to eco-friendly production. By reducing false rejects, minimizing product recalls, and improving detection accuracy, X-Ray inspection systems help manufacturers avoid unnecessary waste and reprocessing. This not only saves energy and materials but also supports long-term sustainability goals—making X-Ray inspection a powerful ally in green manufacturing.

The Intersection of Sustainability and Safety in Manufacturing

Defining Sustainability in Manufacturing

In today’s environmentally conscious market, sustainability has become a central goal across all manufacturing sectors. It involves more than just using recyclable materials—it’s about rethinking the entire production process to reduce waste, optimize energy consumption, and preserve natural resources. Manufacturers are expected to create products with minimal environmental impact while maintaining high operational efficiency. Here, X-Ray inspection becomes a crucial ally. By enabling precise, non-destructive quality control, modern X-Ray inspection equipment allows producers to identify and remove defective items early, before packaging or shipment. This early intervention significantly reduces unnecessary waste and rework, aligning directly with eco-friendly goals.

The Critical Role of Product Safety in Sustainable Production Lines

While reducing a factory’s carbon footprint is important, it cannot come at the cost of product integrity. Sustainability and safety are deeply interconnected: a product that fails quality standards leads to recalls, consumer complaints, and wasted materials—all of which hurt a company’s environmental and economic performance. This is why X-Ray inspection systems are critical tools for sustainable manufacturing. These systems help detect foreign objects such as metal shards, bone fragments, plastic bits, and even glass particles—without disrupting the product or packaging. By integrating X-Ray inspection machines into the production line, manufacturers can maintain the highest standards of safety while avoiding the costly consequences of undetected contaminants.

Challenges Manufacturers Face Balancing Sustainability with Rigorous Safety Standards

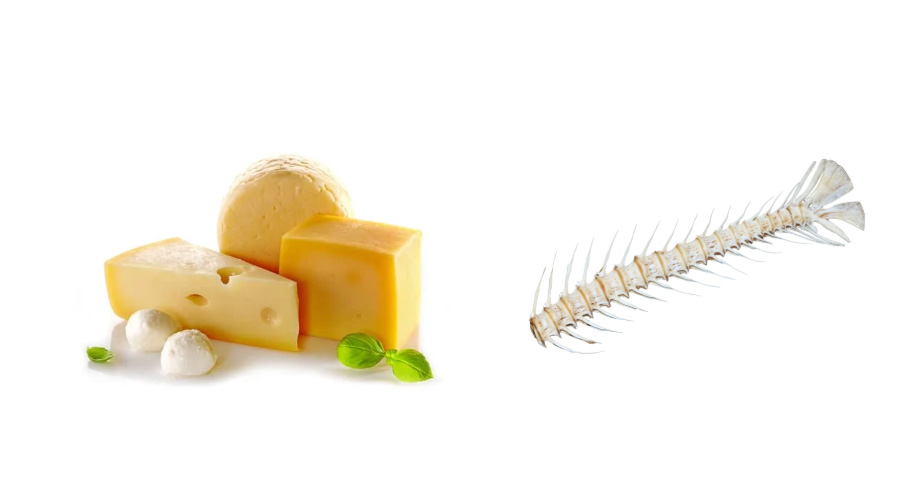

Despite the clear benefits, balancing sustainability with strict safety regulations presents several challenges. For example, overly sensitive detection systems can lead to false positives, mistakenly identifying safe products as contaminated. This results in avoidable waste and unnecessary re-inspection procedures, which contradict the goals of resource efficiency. Additionally, traditional X-Ray inspection equipment that lacks advanced image processing or learning algorithms may struggle to differentiate between actual threats and benign product features (like bones in fish or natural air pockets in cheese). To overcome these challenges, manufacturers are now investing in next-generation X-Ray inspection systems equipped with AI-powered analysis, customizable sensitivity settings, and dual-energy detection. These intelligent technologies ensure precise and consistent results, helping factories uphold safety standards without compromising on sustainability.

What is X-Ray Inspection?

Overview of X-Ray Inspection Technology and Its Applications in Manufacturing

X-Ray inspection is a non-destructive testing method that uses high-energy radiation to inspect the internal structure of products. In manufacturing—especially in the food, pharmaceutical, and packaging industries—X-Ray inspection systems are widely used to ensure product safety, quality, and compliance with international standards. These systems can identify a wide range of contaminants, including metals, glass, bones, stones, ceramics, and even dense plastics. Because of its speed, accuracy, and ability to inspect sealed or packaged items, X-Ray inspection has become a cornerstone of modern quality assurance programs across many sectors.

Types of X-Ray Inspection Equipment and Machines Commonly Used

There are various types of X-Ray inspection machines tailored to different applications and product types. Conveyor-style X-Ray inspection equipment is most commonly used in production lines, where it can scan products in real-time as they move along the belt. For bulk products like nuts or powders, gravity-fed X-Ray systems are often used. There are also pipeline systems for liquid or paste products. Additionally, advanced dual-energy X-Ray inspection machines are designed to distinguish between materials of different densities, helping to reduce false positives and increase detection accuracy. The choice of machine depends on factors like product shape, packaging type, and the nature of potential contaminants.

How X-Ray Inspection Systems Detect Contaminants and Defects Without Damaging Products

One of the most significant advantages of X-Ray inspection systems is their ability to inspect products internally without opening, altering, or damaging them. The system emits a controlled amount of X-rays, which pass through the product and are captured by detectors on the opposite side. Differences in material density and composition cause varying degrees of X-ray absorption, which the system translates into a grayscale image. Advanced image processing algorithms analyze these images to identify foreign objects, voids, cracks, or other anomalies. Because this inspection is non-invasive, manufacturers can maintain full product integrity while ensuring safety and quality. This makes X-Ray inspection equipment an ideal choice for sustainable, high-efficiency production lines.

How X-Ray Inspection Promotes Eco-Friendly Manufacturing

Reducing Product Waste by Minimizing False Rejects and Recalls

One of the most significant environmental benefits of X-Ray inspection in manufacturing is its ability to reduce unnecessary waste. Traditional inspection systems may trigger false positives, leading to good products being discarded. Advanced X-Ray inspection systems—equipped with intelligent algorithms—accurately differentiate between contaminants and normal product variations, thereby minimizing false rejects. This not only cuts down on food or material waste but also prevents costly and environmentally harmful product recalls. By improving precision, X-Ray inspection machines help manufacturers uphold quality without compromising sustainability.

Lowering Resource Consumption Through Precise Detection and Fewer Production Errors

Accurate and early detection of contaminants or defects means fewer batches need to be reworked or discarded, leading to more efficient use of raw materials and energy. X-Ray inspection equipment plays a critical role in identifying issues at the source, reducing the likelihood of downstream problems and resource-intensive corrections. This precision supports lean manufacturing principles, helping companies lower their carbon footprint while maintaining high safety standards.

Enabling Non-Destructive Testing, Reducing the Need for Destructive Quality Control Methods

Unlike some traditional quality control methods that require opening, disassembling, or even destroying the product for inspection, X-Ray inspection is entirely non-destructive. This means products can be evaluated for internal contaminants or structural flaws without altering their form or packaging. By eliminating the need for destructive testing, X-Ray inspection systems preserve product integrity and reduce the number of items wasted in the quality control process. This contributes significantly to more sustainable operations.

Supporting Recyclable and Sustainable Packaging Verification

As more manufacturers shift toward eco-friendly packaging, ensuring compatibility between new materials and inspection systems becomes essential. Advanced X-Ray inspection machines are capable of accurately inspecting products packaged in recyclable or compostable materials such as biodegradable plastics or paper-based films. Moreover, some X-Ray inspection equipment includes customizable detection settings and shielding features that allow the system to work effectively with diverse, sustainable packaging options—without triggering false positives or missing actual contaminants. This adaptability supports greener packaging initiatives while maintaining rigorous quality standards.

Innovations in X-Ray Inspection for Sustainability

Use of Advanced AI and Machine Learning Algorithms to Improve Detection Accuracy

Modern X-Ray inspection systems are increasingly powered by artificial intelligence and machine learning, enabling them to distinguish between true contaminants and harmless product variations with higher precision. By continuously learning from large datasets, these smart X-Ray inspection machines reduce false positives and ensure only truly defective items are flagged. This significantly decreases unnecessary waste, enhances operational efficiency, and supports sustainable production goals. Solutions like the Foodman Intelligent Algorithm Platform (FIAP) represent the forefront of such innovation, bringing both environmental and quality benefits to manufacturers.

Dual-Energy X-Ray Technology for Better Material Discrimination and Lower False Positives

A key advancement in X-Ray inspection equipment is the integration of dual-energy detection technology. This approach utilizes two different energy levels to analyze scanned products, allowing the X-Ray inspection system to better distinguish between materials such as bone, metal, plastic, and organic matter. By improving material discrimination, dual-energy X-Ray inspection machines reduce the chances of false alarms and unnecessary product rejection. This contributes to sustainable practices by minimizing waste and optimizing resource use in food, pharmaceutical, and packaging industries.

Energy-Efficient X-Ray Inspection Machines Designed for Minimal Environmental Impact

Sustainability in manufacturing isn’t just about what is produced—but how it’s produced. New-generation X-Ray inspection machines are engineered with energy efficiency in mind. From optimized power consumption to intelligent standby modes, these machines are designed to deliver high detection performance with a lower environmental footprint. Furthermore, compact and modular designs of X-Ray inspection equipment reduce the use of materials during manufacturing and simplify maintenance, extending the machine’s lifecycle and reducing electronic waste.

Case Studies or Examples

Example of a Food Manufacturer Using X-Ray Inspection to Reduce Waste and Improve Product Safety

A leading frozen seafood producer faced recurring issues with detecting small bones and shell fragments in processed fillets, resulting in frequent product recalls and customer complaints. After integrating an advanced X-Ray inspection system equipped with dual-energy detection and AI-driven recognition into their production line, the company significantly enhanced its contaminant detection accuracy.

The X-Ray inspection machine was able to differentiate between edible fish tissue and non-edible bone with high precision, reducing false positives and allowing for more efficient processing. As a result, the company reported a 30% reduction in product waste and a noticeable improvement in customer satisfaction. Beyond safety, this deployment of X-Ray inspection equipment also contributed to sustainability by reducing rejected product volume and optimizing raw material usage.

Pharmaceutical Industry Application Ensuring Both Compliance and Sustainability Through X-Ray Inspection

In the pharmaceutical sector, a major capsule manufacturer adopted X-Ray inspection technology to ensure that every unit was free from foreign contaminants like metal shards, glass particles, or broken capsules. By employing a high-resolution X-Ray inspection system with real-time imaging and automatic rejection mechanisms, the facility maintained full compliance with stringent international quality standards.

Moreover, this X-Ray inspection equipment played a crucial role in sustainability efforts. Its non-destructive testing capability meant fewer samples were discarded during quality checks, conserving valuable raw materials. Additionally, smart X-Ray inspection machines helped optimize packaging processes by verifying fill levels and detecting inconsistencies, reducing rework and material waste.

These two examples demonstrate how X-Ray inspection is more than a quality control tool—it’s a driver of both regulatory compliance and environmental responsibility in modern manufacturing.

Best Practices for Integrating X-Ray Inspection in Sustainable Manufacturing

Regular Maintenance and Calibration to Optimize Machine Efficiency and Lifespan

One of the most effective ways to ensure the sustainability and reliability of an X-Ray inspection system is through regular maintenance and calibration. Over time, even the most advanced X-Ray inspection machines may experience sensor drift or wear, which can reduce detection accuracy and increase the likelihood of false positives or missed contaminants. By scheduling consistent system checks, cleaning optical components, and updating software, manufacturers can extend the operational lifespan of their X-Ray inspection equipment, reduce energy waste, and maintain high standards of product safety.

Operator Training for Maximizing System Capabilities and Minimizing Errors

Even the most intelligent X-Ray inspection systems require knowledgeable operators to run effectively. Proper training ensures that staff can interpret inspection results accurately, adjust settings for different product profiles, and respond promptly to alerts. Skilled operators are essential in optimizing the performance of X-Ray inspection machines, particularly when it comes to minimizing false rejects and maximizing throughput. Investing in training not only boosts operational efficiency but also aligns with sustainability goals by reducing unnecessary waste and downtime.

Collaboration with Intelligent Solution Providers Focusing on Sustainable Technologies

Partnering with a provider that prioritizes both innovation and sustainability can make a significant difference. Leading manufacturers of X-Ray inspection equipment now offer systems integrated with AI-driven algorithms, energy-efficient components, and environmentally conscious designs. Collaborating with such solution providers ensures that businesses receive tailored support, continuous system improvements, and access to the latest in sustainable X-Ray inspection technology. These partnerships help align manufacturing processes with environmental goals without compromising on safety or quality.

Conclusion

Recap of How X-Ray Inspection Plays a Crucial Role at the Intersection of Sustainability and Safety

In today’s manufacturing environment, balancing ecological responsibility with product integrity is more vital than ever. X-Ray inspection stands out as a powerful enabler of both goals. By leveraging advanced X-Ray inspection systems, manufacturers can detect contaminants and defects with precision—without compromising the product itself. This non-destructive testing capability not only protects consumer safety but also significantly reduces unnecessary waste, making X-Ray inspection equipment a cornerstone of sustainable and safe production practices.

Encouragement for Manufacturers to Adopt Smart Inspection Technologies for a Greener Future

As industries evolve, embracing smarter technologies is no longer optional—it’s a necessity. Manufacturers are encouraged to invest in intelligent X-Ray inspection machines that incorporate features like AI-based material classification, energy-efficient operation, and dual-energy imaging. These innovations not only enhance detection performance but also help align inspection processes with sustainability goals, promoting a greener, more responsible manufacturing future.

Final Thoughts on the Evolving Role of Technology in Promoting Eco-Friendly Manufacturing Practices

Technology continues to redefine what’s possible in sustainable manufacturing. With continued innovation, X-Ray inspection equipment is becoming more adaptive, efficient, and environmentally friendly. As manufacturers strive to meet stricter environmental regulations and growing consumer expectations, integrating advanced X-Ray inspection systems into production lines will be key. The path to a cleaner, safer manufacturing landscape lies in the smart application of inspection technology that champions both quality and sustainability.

FAQ

Q1: Can X-Ray inspection equipment be used with recyclable or biodegradable packaging?

A: Yes. Modern X-Ray inspection machines are compatible with sustainable packaging materials, including recyclable plastics, biodegradable films, and compostable paper-based wraps. Customizable shielding and detection settings ensure effective performance without generating false positives, supporting the transition to greener packaging solutions.

Q2: How does AI enhance the performance of X-Ray inspection systems?

AI-driven X-Ray inspection systems—such as those powered by platforms like FIAP (Foodman Intelligent Algorithm Platform)—continuously learn from image datasets to improve detection accuracy. They reduce false alarms, optimize inspection speed, and enable smart decision-making, which collectively improves product quality and reduces waste for more sustainable production.

Q3: What challenges do manufacturers face when balancing sustainability and safety, and how does X-Ray technology help?

A: Challenges include over-sensitive systems causing false rejects, inefficient detection of complex contaminants, and compatibility issues with new packaging materials. Advanced X-Ray inspection equipment addresses these by offering precise, customizable, and intelligent solutions that reduce waste and ensure compliance—supporting both environmental and safety priorities.