Introduction

The Rise of Eco-Friendly Packaging in Food and Consumer Goods Industries

X-Ray inspection is playing an increasingly vital role as industries transition toward eco-friendly packaging. In the food and consumer goods sectors, the push for sustainability has led to a surge in the adoption of biodegradable films, compostable trays, paper-based wrappers, and other environmentally conscious materials. While these alternatives reduce environmental impact, they also introduce new complexities for manufacturers—especially in ensuring product safety and contaminant detection.

Unlike traditional packaging, eco-friendly materials often vary in density, opacity, and structure, which can challenge older inspection methods. As a result, manufacturers are now turning to X-Ray inspection systems to maintain reliable quality control even when using novel packaging solutions.

Why Sustainability Matters: Regulatory Pressure and Consumer Demand

Environmental sustainability is no longer a niche trend—it’s a mainstream requirement driven by growing consumer expectations and increasing regulatory mandates. Governments across the globe are enacting stricter rules regarding packaging materials, waste reduction, and recyclability. Consumers, in parallel, are demanding brands reduce their carbon footprints and adopt eco-conscious production practices.

For manufacturers, the shift to green packaging is not without risk. Some sustainable materials interfere with traditional contaminant detection technologies, raising concerns about safety and compliance. To stay ahead, businesses must equip their operations with inspection solutions that are both flexible and effective—such as advanced X-Ray inspection machines that can inspect through paper, bioplastics, and multilayer films without compromising performance.

The Intersection of Sustainable Materials and Product Safety

While eco-friendly packaging supports environmental goals, it can complicate contaminant detection. Materials like recycled cardboard, molded pulp, and plant-based polymers may absorb or scatter signals from metal detectors and optical systems, reducing the effectiveness of traditional inspection tools.

X-Ray inspection equipment bridges this gap by analyzing product and package density, not magnetic or optical characteristics. Whether it’s detecting metal fragments in a paper pouch or identifying glass shards in compostable film, an X-Ray inspection system ensures contaminants are reliably found. As manufacturers strive to meet both sustainability and safety targets, X-Ray inspection technology becomes a critical component of future-proof packaging and production strategies.

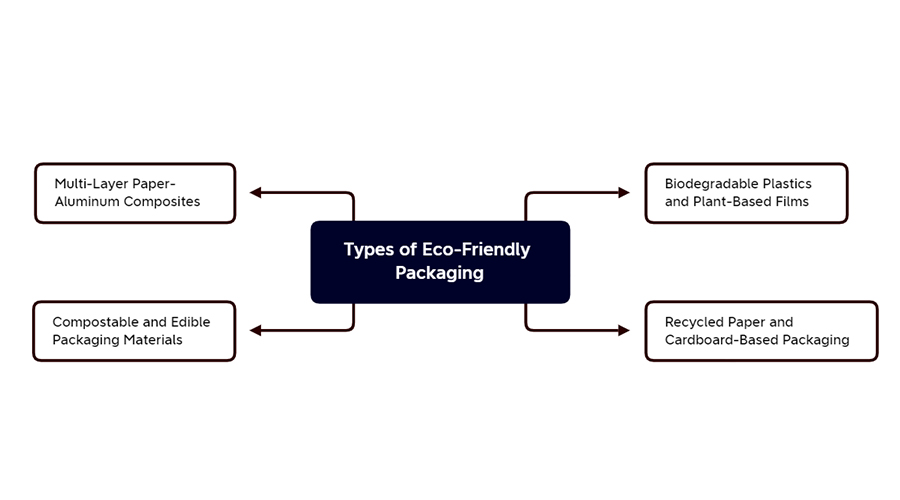

Types of Eco-Friendly Packaging

Biodegradable Plastics and Plant-Based Films

Biodegradable plastics and plant-based films are increasingly popular in eco-friendly packaging due to their reduced environmental impact. However, these materials present unique challenges for quality control. X-Ray inspection systems are well-suited for inspecting biodegradable films because X-Ray inspection machines can penetrate these materials effectively. Using advanced X-Ray inspection equipment, manufacturers can detect contaminants without compromising the integrity of these sustainable packaging solutions, ensuring both product safety and environmental responsibility.

Recycled Paper and Cardboard-Based Packaging

Recycled paper and cardboard-based packaging are common choices for sustainable consumer goods. While environmentally friendly, their fibrous structure and variable density can complicate inspection processes. Traditional detection methods may struggle with such materials, but X-Ray inspection machines excel here by analyzing material density differences. An X-Ray inspection system provides a non-destructive method to inspect products packed in recycled paper or cardboard, detecting foreign objects reliably and supporting sustainable packaging efforts.

Compostable and Edible Packaging Materials

Compostable and edible packaging materials, made from substances like starch, cellulose, or seaweed, offer innovative eco-friendly alternatives. These materials require sensitive inspection methods that do not damage the packaging or product. X-Ray inspection equipment is particularly effective because it uses high-energy X-rays to identify contaminants based on density variations rather than surface appearance. X-Ray inspection machines enable manufacturers to maintain product safety while adopting compostable or edible packaging solutions, balancing sustainability with stringent quality control.

Multi-Layer Paper-Aluminum Composites

Multi-layer paper-aluminum composites combine sustainability with excellent barrier properties but create challenges for conventional detection technologies due to their metal layers. Metal detectors may produce false positives or miss contaminants behind metallic films. In contrast, an X-Ray inspection system can penetrate these composite layers, using density-based imaging to detect hidden foreign objects. By deploying advanced X-Ray inspection equipment, manufacturers can ensure high safety standards even in eco-friendly packages that use complex multi-layer materials.

Challenges These Materials Pose to X-Ray Detection

Density Inconsistency and Its Effect on Image Clarity

Eco-friendly packaging materials, such as biodegradable plastics and recycled paper, often exhibit significant density inconsistencies. These variations can impact the clarity of images produced by X-Ray inspection systems. Unlike traditional packaging materials with uniform density, organic and plant-based films cause uneven X-Ray absorption. This inconsistency challenges X-Ray inspection machines to differentiate between contaminants and the natural variations in packaging, requiring advanced image processing algorithms within the X-Ray inspection equipment to maintain accurate detection.

Increased False Positives or False Negatives Due to Organic-Based Packaging

Organic-based packaging materials often contain fibers, moisture, or air pockets that can interfere with X-Ray signals. As a result, X-Ray inspection systems might generate more false positives—incorrectly flagging safe products as contaminated—or false negatives, where actual contaminants go undetected. Optimizing the sensitivity and calibration of the X-Ray inspection machine is crucial to balance detection accuracy and reduce these errors, especially when inspecting eco-packaged food and consumer goods.

Reduced Penetration Efficiency in Fiber-Rich or Multilayered Materials

Fiber-rich packaging like recycled cardboard or multilayer composites (e.g., paper-aluminum laminates) can reduce the penetration efficiency of X-Ray inspection machines. These dense or multilayered materials absorb or scatter X-rays, making it harder for the X-Ray inspection equipment to detect foreign objects inside. To overcome this, manufacturers rely on high-energy X-Ray inspection systems and advanced dual-energy technologies that enhance penetration and improve contaminant visibility through complex packaging.

The growing variety of eco-friendly packaging formats lacks unified industry standards, complicating the calibration process of X-Ray inspection equipment. Each packaging type may require specific sensitivity settings and detection thresholds for optimal performance. This variability demands that X-Ray inspection machines be highly configurable, with adaptable software and hardware settings to handle different materials effectively. Ensuring reliable detection across diverse eco-packaging products requires continuous calibration and validation, making the role of X-Ray inspection systems even more critical.

Lack of Standardization in Eco-Packaging Complicates Machine Calibration

The growing variety of eco-friendly packaging formats lacks unified industry standards, complicating the calibration process of X-Ray inspection equipment. Each packaging type may require specific sensitivity settings and detection thresholds for optimal performance. This variability demands that X-Ray inspection machines be highly configurable, with adaptable software and hardware settings to handle different materials effectively. Ensuring reliable detection across diverse eco-packaging products requires continuous calibration and validation, making the role of X-Ray inspection systems even more critical.

How Modern X-Ray Inspection Systems Address These Issues

Adaptive Contrast Enhancement and Auto-Threshold Calibration

Modern X-Ray inspection equipment is equipped with advanced adaptive contrast enhancement technologies that improve image clarity even when faced with density inconsistencies in eco-friendly packaging. These X-Ray inspection systems automatically adjust detection thresholds based on real-time analysis of packaging characteristics, ensuring that contaminants are reliably distinguished from the variable textures and densities found in biodegradable plastics or recycled materials. This auto-threshold calibration reduces false positives and false negatives, making the inspection process more efficient and accurate.

Dual-Energy X-Ray Inspection for Complex Material Discrimination

Dual-energy X-Ray inspection machines have become indispensable tools for handling the complexities of sustainable packaging. By capturing images at two different energy levels, these X-Ray inspection systems can differentiate between multiple material types within multilayered or fiber-rich packaging. This enhanced material discrimination allows the X-Ray inspection equipment to detect contaminants hidden within paper-aluminum composites or plant-based films more effectively than traditional single-energy systems.

Machine Learning Algorithms Trained on Sustainable Packaging Scenarios

To further enhance detection accuracy, many advanced X-Ray inspection machines now incorporate machine learning algorithms specifically trained on eco-friendly packaging scenarios. These intelligent systems analyze vast datasets to recognize subtle differences between packaging materials and foreign objects, even when traditional density contrasts are minimal. By continuously learning and adapting, the X-Ray inspection system improves over time, offering superior contaminant detection performance tailored to the challenges posed by sustainable packaging.

Software Updates and Packaging-Specific Presets

X-Ray inspection equipment providers regularly release software updates that include new presets optimized for emerging eco-friendly packaging formats. These presets allow manufacturers to quickly configure their X-Ray inspection machines for different biodegradable plastics, compostable films, or recycled paper types without extensive manual recalibration. This packaging-specific approach ensures consistent inspection quality and reduces downtime, enabling seamless integration of X-Ray inspection systems into modern, sustainable production lines.

Best Practices for Manufacturers Using Eco-Friendly Packaging

Packaging Material Selection with Inspection Compatibility in Mind

When adopting eco-friendly packaging, manufacturers should carefully consider the compatibility of materials with X-Ray inspection equipment. Selecting biodegradable plastics, plant-based films, or recycled paper that maintain consistent density and minimal interference helps optimize the performance of X-Ray inspection systems. Early coordination between packaging designers and quality control teams ensures that sustainable packaging choices do not compromise the effectiveness of contaminant detection by X-Ray inspection machines.

Collaborative Testing with X-Ray Inspection Equipment Providers

Successful implementation of X-Ray inspection systems in sustainable packaging lines requires close collaboration between manufacturers and X-Ray inspection equipment providers. Joint testing allows both parties to evaluate how different eco-friendly materials affect image quality and detection sensitivity. This cooperation enables fine-tuning of the X-Ray inspection system settings to minimize false positives and false negatives, ensuring reliable product safety without sacrificing production efficiency.

Regular Calibration and Validation with Reference Test Packs

Maintaining optimal detection performance demands regular calibration and validation of X-Ray inspection machines using reference test packs that simulate real packaging conditions. For eco-friendly packaging, which can vary widely in material composition and thickness, consistent calibration is essential to adapt the X-Ray inspection system to evolving product lines. Using certified reference samples helps verify that the system meets detection thresholds and complies with regulatory standards throughout its operational life.

Operator Training on New Packaging Profiles

Introducing new sustainable packaging profiles calls for updated operator training focused on the specific challenges of inspecting eco-friendly materials. Training programs should cover how X-Ray inspection equipment interprets different packaging types, adjustment of sensitivity settings, and handling of alarms triggered by packaging variability. Well-trained operators ensure that the X-Ray inspection system is utilized to its full potential, maintaining high standards of safety and reducing unnecessary product rejects.

Case Studies or Real-World Applications

Organic Snack Company Using Compostable Packaging and X-Ray Inspection

An organic snack manufacturer recently transitioned to compostable packaging to meet growing consumer demand for sustainability. To ensure product safety, they integrated an advanced X-Ray inspection system into their production line. Despite the challenges posed by the new packaging’s organic composition, the X-Ray inspection machine effectively detected foreign contaminants such as metal fragments and stones. This case demonstrates how modern X-Ray inspection equipment can adapt to eco-friendly materials while maintaining stringent quality control.

Powdered Supplements in Biodegradable Film Bags: Detection Success

A leading supplier of powdered nutritional supplements adopted biodegradable film bags to reduce plastic waste. Using a specialized X-Ray inspection machine calibrated for these films, the company achieved high detection accuracy of contaminants including glass shards and dense plastic particles. The food X-Ray inspection system’s real-time imaging and dual-energy technology played a key role in overcoming the density variations caused by the biodegradable films, ensuring that every package met safety standards.

Lessons from Switching from Plastic to Recycled Paper Pouches

A beverage powder producer shifted from traditional plastic packaging to recycled paper pouches to enhance their environmental profile. The move initially presented inspection challenges due to the fiber-rich, multilayered nature of paper-based packaging. However, by working closely with their X-Ray inspection equipment provider, they optimized their X-Ray inspection system through software updates and custom presets. This collaboration reduced false positives and improved contaminant detection, highlighting the importance of adapting X-Ray inspection machines to new packaging materials for sustained product safety.

Future Trends and Innovations

AI-Based Detection Models for Eco-Material Variance

As eco-friendly packaging materials continue to evolve in structure and composition, the future of X-Ray inspection lies in AI-powered adaptability. Manufacturers of X-Ray inspection systems are now integrating machine learning algorithms that can automatically recognize and adjust to the varying densities and textures of sustainable packaging. These AI-driven models help X-Ray inspection machines distinguish between benign variations in packaging and actual contaminants—reducing false positives while maintaining a high level of sensitivity. This innovation is particularly vital as biodegradable, compostable, and plant-based films become more prevalent.

Industry Movement Toward X-Ray-Friendly Sustainable Packaging

Sustainability and inspectability no longer need to be at odds. A growing number of packaging suppliers are now collaborating with X-Ray inspection equipment manufacturers to develop materials that maintain eco-credentials without compromising detection performance. These X-Ray-friendly sustainable materials are engineered with more consistent density profiles, improved barrier properties, and better imaging contrast. As this movement accelerates, it ensures that food X-Ray inspection remains accurate and effective, even as packaging formats shift toward greener alternatives.

Regulatory Harmonization and Inspection Standardization for Green Packaging

With global regulatory bodies placing increased emphasis on sustainability and food safety, the industry is moving toward unified standards for inspecting eco-packaged goods. Organizations such as the FDA, BRCGS, and IFS are working to define clear guidelines for how X-Ray inspection systems should handle biodegradable and recyclable materials. This trend supports the development of standardized validation protocols, enabling consistent performance evaluation across different types of X-Ray inspection equipment. As regulations catch up with innovation, both manufacturers and inspectors will benefit from more predictable outcomes and compliance pathways.

Conclusion

Eco-Friendly Packaging Is Here to Stay—But It’s Not Inspection-Proof

The shift toward eco-friendly packaging is more than a trend—it’s becoming an industry standard driven by environmental responsibility and consumer expectations. However, while biodegradable films, recycled paper, and compostable pouches support sustainability goals, they also present new challenges for product safety. These materials can interfere with traditional detection technologies, making it clear that no packaging—no matter how green—is entirely inspection-proof. This underscores the growing importance of adopting advanced X-Ray inspection equipment that can adapt to changing material profiles.

X-Ray Inspection Systems Must Evolve to Support Safety and Sustainability

To maintain high safety standards in a world of evolving packaging materials, X-Ray inspection systems must continue to innovate. Modern X-Ray inspection machines now incorporate dual-energy imaging, adaptive algorithms, and material-specific presets to address the unique characteristics of sustainable packaging. These advancements ensure that X-Ray inspection remains effective even when inspecting through fiber-rich or multilayer eco-pack formats. As packaging innovation accelerates, inspection technology must keep pace to safeguard both the product and the planet.

Forward-Looking Manufacturers Must Embrace Both Environmental and Technological Innovation

The most successful manufacturers will be those who balance environmental responsibility with cutting-edge quality control. Integrating high-performance X-Ray inspection systems into production lines demonstrates a commitment to both consumer safety and sustainable business practices. By collaborating with X-Ray inspection equipment providers, companies can validate new packaging materials, fine-tune detection parameters, and ensure compliance with evolving regulatory standards. In this new era, embracing both eco-friendly design and robust X-Ray inspection capabilities is no longer optional—it’s essential for future-ready operations.

FAQ

Q: What types of eco-friendly packaging pose the biggest challenges to X-Ray inspection machines?

A: Fiber-rich materials like recycled paper, multilayer composites (e.g., paper-aluminum), and compostable films can affect image clarity and reduce X-Ray penetration efficiency. These packaging types may lead to increased false positives or false negatives if the X-Ray inspection machine is not properly calibrated.

Q: Do I need to recalibrate my X-Ray inspection system when switching to eco-friendly packaging?

A: Yes. Different sustainable packaging materials can affect detection performance. It’s recommended to recalibrate and validate your X-Ray inspection machine using reference test packs whenever introducing a new packaging type.

Q: Is it possible to inspect multilayer paper-aluminum composite packaging using X-Ray inspection machines?

A: Absolutely. Unlike metal detectors, which often fail with such materials, X-Ray inspection systems can detect contaminants behind metallic layers by analyzing density variations, ensuring reliable inspection through multilayer composites.