Introduction

Importance of Safety and Quality in the Growing Pet Food Industry

The global pet food industry is experiencing rapid growth, driven by increasing pet ownership and the humanization of pets. As consumers treat pets like family, the safety and nutritional quality of pet food have become top priorities. Just like in human food processing, any contamination in pet food—whether it’s metal fragments, bone shards, or packaging defects—can pose serious health risks. Therefore, robust quality assurance processes, including reliable food X-Ray inspection, are crucial to meet both regulatory requirements and consumer trust.

Rising Consumer Expectations for Pet Food Transparency and Purity

Today’s pet owners are more informed and demanding than ever. They expect full transparency about ingredients, sourcing, and safety standards in pet food production. Any breach in quality can lead to customer backlash, brand damage, or even legal consequences. As a result, manufacturers are investing in advanced technologies like X-Ray inspection systems to ensure that their products are not only nutritionally sound but also contaminant-free. The implementation of a food X-Ray inspection process adds a vital layer of protection and reassurance across the supply chain.

Why Traditional Inspection Methods May Fall Short

Traditional inspection methods such as metal detectors, visual checks, and weight-based sorting have long been used in the pet food industry. However, these techniques often fall short when it comes to detecting non-metallic contaminants like glass, bones, stones, or high-density plastics. Furthermore, metal detectors struggle to operate effectively with metallized packaging, which is common in pet food products. In contrast, X-Ray inspection equipment can detect a wide range of foreign objects based on density differences, offering far greater versatility and reliability.

Brief Introduction to X-Ray Inspection Systems as a Modern Solution

X-Ray inspection machines have become a gold standard in pet food quality assurance. Unlike older systems, a modern X-Ray inspection system provides detailed imaging of products as they move through the production line, allowing real-time identification of contaminants inside sealed packaging. These machines are highly sensitive and can detect both metallic and non-metallic foreign materials with minimal false positives. From raw material screening to final package inspection, food X-Ray inspection delivers consistent performance, helping manufacturers safeguard both their products and their reputation.

Common Contaminants and Defects in Pet Food

Maintaining the safety and quality of pet food is a top priority for manufacturers. X-Ray inspection plays a critical role in identifying and eliminating a wide range of contaminants and packaging defects that could compromise pet health or damage brand trust. Modern X-Ray inspection systems are designed to detect non-visible threats in both raw ingredients and finished products, offering unmatched precision and reliability compared to traditional detection methods. Below are some of the most common hazards found in pet food production and how X-Ray inspection equipment can address them.

Metal Fragments

Metal contamination is one of the most frequent and dangerous issues in pet food manufacturing. Fragments from worn processing equipment—such as screws, blades, or filters—can unintentionally enter the production line. Traditional metal detectors often struggle with products that have high moisture or salt content, both common in pet food.

X-Ray inspection machines overcome these limitations by detecting metal fragments based on density differences rather than magnetic properties. Whether it’s ferrous, non-ferrous, or stainless steel, X-Ray inspection systems can pinpoint contaminants with high accuracy, even in foil-sealed or high-density packaging.

Bone Shards in Meat-Based Formulas

Meat-based pet food, particularly wet and semi-moist formats, may contain residual bone shards that pose a choking or injury risk to pets. These bone fragments can be small, irregularly shaped, and difficult to detect visually or with traditional sorting equipment.

Food X-Ray inspection systems are specifically calibrated to detect such low-density foreign objects. They scan each package in real time, analyzing the density and shape of internal content to locate bone shards, ensuring only safe products reach consumers. This makes X-Ray inspection equipment a reliable solution for pet food producers using animal-based ingredients.

Stones, Glass, and Dense Plastic Particles

Natural raw materials—such as grains, vegetables, or fish meal—may introduce contaminants like stones or glass into pet food. Similarly, small pieces of dense plastic from tools, bins, or packaging material can unintentionally end up in the final product.

X-Ray inspection systems are highly effective at detecting these non-metallic threats. By measuring the X-ray absorption of each object inside a sealed package, an X-Ray inspection machine can highlight even tiny foreign materials with similar color or texture to the product itself. This advanced capability is one reason why many leading pet food brands rely on X-Ray inspection equipment for comprehensive contaminant detection.

Defective Packaging

Beyond contaminant detection, packaging integrity is another critical quality checkpoint. Broken seals, punctured bags, or structural deformities not only reduce shelf life but also invite bacterial contamination, putting pets at risk.

Modern X-Ray inspection machines can be equipped with features to assess packaging consistency. They detect irregularities such as unsealed edges, air gaps, or crushed compartments during the production line process. Using X-Ray inspection equipment, manufacturers can ensure that packaging defects are flagged and removed before products are shipped, helping to uphold brand reputation and regulatory compliance.

How X-Ray Inspection Systems Work in Pet Food Production

Density-Based Detection: How X-Rays Identify Foreign Bodies

X-Ray inspection works on the principle of density contrast. When X-rays pass through a product, they are absorbed differently by materials of varying densities. Foreign bodies such as metal, bone, glass, or stones appear as anomalies in the resulting image because they absorb more X-ray energy than the surrounding food product.

An X-Ray inspection system uses this principle to scan sealed bags, cans, or trays of pet food, capturing internal images that are analyzed in real time. The system highlights discrepancies in density, enabling operators or automated software to detect even small contaminants. This makes X-Ray inspection equipment ideal for complex pet food formulations, including those with high moisture or protein content.

Differences Between X-Ray Inspection Machines and Metal Detectors

While metal detectors are still widely used in the food industry, they have limitations—particularly when inspecting products packaged in metalized films or containing high salt or moisture levels. These conditions can interfere with electromagnetic signals, causing false readings or missed detections.

In contrast, X-Ray inspection machines are unaffected by conductivity or packaging type. They can detect a broader range of contaminants, including glass, stones, hard plastics, and bone, in addition to all metal types. This broader detection capability makes X-Ray inspection systems far more versatile and reliable for pet food applications, especially when diverse ingredients and complex packaging are involved.

Inline, High-Speed Integration with Pet Food Production Lines

Modern X-Ray inspection systems are engineered for seamless integration into high-speed production environments. Whether a facility is producing kibble, wet food, or freeze-dried treats, X-Ray inspection equipment can be installed directly on the line, inspecting every unit without slowing down operations.

These systems are designed to match conveyor speeds and automatically adapt to different package sizes and formats. With minimal footprint and modular design, an X-Ray inspection machine fits easily into existing lines and complies with hygiene and sanitation requirements in pet food manufacturing.

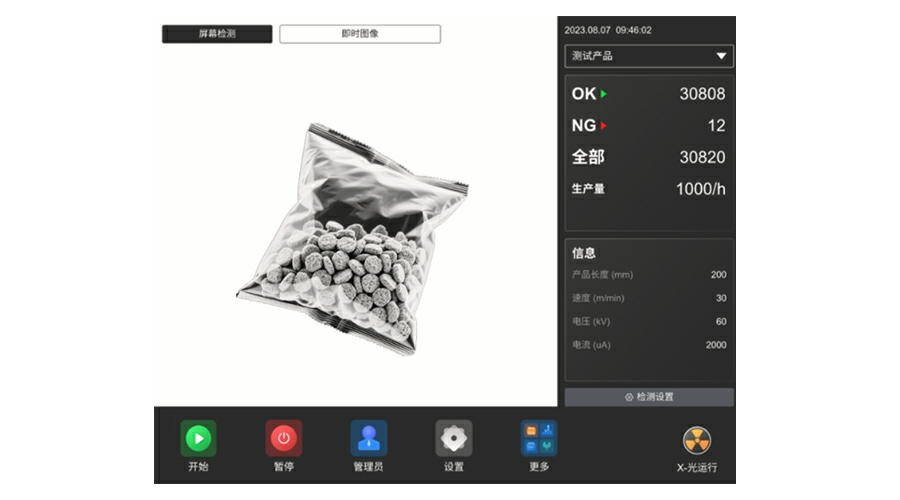

Real-Time Imaging and Auto-Rejection Mechanisms

One of the standout advantages of X-Ray inspection systems is their ability to perform real-time imaging and analysis. As each product passes through the system, high-resolution images are instantly generated and processed using sophisticated algorithms. If a contaminant or defect is detected, the X-Ray inspection machine triggers an auto-rejection mechanism—removing the compromised item from the line without human intervention.

This real-time operation not only enhances safety but also reduces labor costs and minimizes waste. Advanced X-Ray inspection equipment can store image records for traceability and quality assurance, offering manufacturers full transparency into the inspection process and helping meet industry standards and audits.

Application Scenarios in Pet Food Manufacturing

In modern pet food production, maintaining consistent quality across various product types requires advanced inspection technology. X-Ray inspection systems are now widely deployed at different stages of the production process to detect foreign bodies, ensure uniformity, and verify packaging integrity. Whether dealing with dry kibble, wet food, or specialty treats, X-Ray inspection equipment plays a pivotal role in safeguarding pet health and brand reputation.

Detection in Dry Kibble

Dry kibble is the most common form of pet food, and it demands precise inspection due to high-speed production rates and bulk packaging formats. X-Ray inspection machines are used to detect physical contaminants such as metal fragments, bone, or dense plastic that may result from machinery wear or ingredient impurities.

Additionally, an X-Ray inspection system helps monitor product uniformity by identifying clumps, broken pieces, or underfilled sections within each pack. Because X-Ray inspection evaluates density rather than appearance, it ensures accurate results even with visually similar defects.

Inspection of Wet/Canned Pet Food

Canned and wet pet foods pose unique challenges, particularly with the risk of bone shards in meat-based formulas and the potential for broken glass or damaged seals. Traditional detection tools often struggle in metal cans or foil-sealed trays, where electromagnetic interference or opacity obstructs inspection.

X-Ray inspection equipment excels in these environments. It can inspect through metal containers to identify density anomalies—pinpointing hidden contaminants like bone fragments or small glass pieces. Moreover, X-Ray inspection machines verify seal integrity and detect bulging or under-vacuum packaging conditions that may indicate spoilage or improper processing.

Inspection of Freeze-Dried or Semi-Moist Treats

Freeze-dried and semi-moist pet treats are becoming increasingly popular, particularly in premium and functional product segments. However, their varied shapes, textures, and densities make them difficult to inspect using conventional methods.

Here, X-Ray inspection systems shine by detecting foreign materials without being hindered by product irregularities. Whether the treats are packed in pouches, jars, or trays, X-Ray inspection machines can identify hard contaminants like metal, stones, or bone, helping manufacturers uphold quality and safety across product lines.

Final Packaging Inspection: Aluminum Trays, Pouches, Plastic Tubs

At the end of the line, final packaging inspection ensures that every sealed product meets safety and quality standards. With many pet foods packaged in aluminum trays, laminated pouches, or plastic tubs, traditional metal detectors fall short due to interference from packaging materials.

X-Ray inspection equipment overcomes this by evaluating internal content through any material type. Final checks using an X-Ray inspection machine verify product presence, identify seal defects, and detect contaminants missed during upstream inspection. This final safeguard ensures that only safe, defect-free pet food reaches store shelves and pet owners.

Benefits of Using X-Ray Inspection Systems for Pet Food

Adopting advanced X-Ray inspection systems in pet food production offers a wide array of benefits—from enhanced safety to regulatory compliance and brand protection. As consumer expectations and industry regulations grow stricter, the need for reliable and efficient X-Ray inspection equipment becomes increasingly important.

High Accuracy and Low False-Positive Rates

Modern X-Ray inspection machines are designed with sophisticated image processing and dual-energy capabilities, enabling them to distinguish between actual contaminants and harmless density variations in pet food. Whether detecting bone fragments in meat-based products or identifying dense plastic in dry kibble, an X-Ray inspection system delivers superior accuracy with minimal false alarms. This precision reduces unnecessary waste and ensures that only truly compromised products are rejected.

Non-Destructive, Safe for All Packaging Types

Unlike some inspection methods that can be limited by metalized or opaque packaging, X-Ray inspection equipment can safely and non-destructively scan through any packaging type—including aluminum trays, plastic tubs, foil pouches, or cans. This versatility makes X-Ray inspection systems ideal for the diverse formats used in the pet food industry, without compromising the integrity or appearance of the final product.

Supports Compliance with International Standards

Global pet food manufacturers must adhere to stringent safety and quality regulations set by bodies such as the FDA, FSSC 22000, BRCGS, and IFS. X-Ray inspection machines support compliance by providing verifiable, auditable data and consistent inspection performance. By integrating X-Ray inspection systems into production lines, manufacturers can ensure traceability and maintain quality documentation required for regulatory audits and international exports.

Enhances Brand Reputation and Reduces Recall Risks

A single contamination incident can lead to massive product recalls, damaging both consumer trust and business reputation. Using X-Ray inspection equipment as part of a robust quality assurance program greatly reduces this risk. By reliably identifying and removing foreign materials before products reach store shelves, X-Ray inspection systems help protect brand integrity and foster long-term customer loyalty in an increasingly competitive pet food market.

Key Features to Look for in Pet Food X-Ray Inspection Equipment

When selecting X-Ray inspection equipment for pet food production, it’s crucial to consider features that address the unique challenges of this industry. Advanced X-Ray inspection systems offer a range of capabilities that ensure both safety and operational efficiency.

Dual-Energy Detection

Pet food products often come in diverse packaging types, some with high-fat content or multilayer structures that can complicate inspection. Modern X-Ray inspection machines with dual-energy detection can differentiate materials based on their density and composition. This capability enhances the detection of contaminants hidden within complex packaging or fatty products, ensuring that foreign bodies are reliably identified without false positives.

Automatic Calibration and Adaptive Thresholding

Maintaining consistent inspection accuracy is essential in high-throughput pet food lines. The latest X-Ray inspection systems incorporate automatic calibration and adaptive thresholding features, allowing the machine to self-adjust to variations in product density and packaging. This reduces the need for manual intervention and minimizes downtime, ensuring continuous and reliable inspection performance.

Hygienic Design (IP65/IP66-Rated) Suitable for Food Environments

Pet food production environments require stringent hygiene standards. X-Ray inspection equipment designed with hygienic features, such as IP65 or IP66 ratings, ensures protection against dust and water ingress. This robust design facilitates easy cleaning and prevents contamination, making the inspection machines safe and compliant with food safety regulations.

Data Logging and Traceability Features

Traceability is a critical component of quality assurance in pet food manufacturing. Advanced X-Ray inspection systems come equipped with data logging functionalities that record inspection results, reject rates, and machine performance metrics. This data can be used for audits, compliance verification, and continuous process improvement, helping manufacturers maintain transparency and confidence in their safety protocols.

By choosing X-Ray inspection equipment with these key features, pet food manufacturers can enhance their contaminant detection capabilities while maintaining regulatory compliance and operational efficiency. Investing in a sophisticated X-Ray inspection system ultimately supports product safety, brand integrity, and consumer trust.

Challenges and Considerations

When implementing X-Ray inspection systems in pet food production, manufacturers face unique challenges and important considerations. Understanding these factors helps optimize the use of X-Ray inspection equipment for maximum safety and efficiency.

Variations in Product Density and Shape

Pet food products come in a wide range of shapes and densities, from hard kibble to soft treats. These variations can complicate detection for X-Ray inspection machines, as inconsistent product profiles may affect image quality and contaminant visibility. An advanced X-Ray inspection system must adapt to these differences to maintain reliable detection without increasing false rejects.

High Oil/Fat Content May Affect Image Clarity

Many pet food products, especially meat-based formulas or treats, contain high levels of fat and oil. These components can reduce the clarity of images produced by the X-Ray inspection equipment by altering X-Ray absorption characteristics. This challenge requires the use of specialized X-Ray inspection machines with enhanced imaging algorithms or dual-energy technology to accurately identify foreign objects despite high-fat content.

Calibration Needs for Different Product Types

Because pet food production involves diverse products and packaging, calibration of the X-Ray inspection system is essential for each type. Regular and precise calibration ensures the machine’s sensitivity and threshold settings are optimized, preventing both missed contaminants and excessive false alarms. Manufacturers must allocate time and resources to maintain their X-Ray inspection equipment calibrated for changing production lines.

Cost vs. ROI Analysis for SMEs

Small and medium-sized enterprises (SMEs) in the pet food industry often face budget constraints when investing in advanced X-Ray inspection machines. While these systems provide critical safety benefits, the upfront costs can be significant. It’s important for SMEs to perform a thorough cost versus return on investment (ROI) analysis, considering factors such as reduced recalls, enhanced brand reputation, regulatory compliance, and improved production efficiency that result from effective X-Ray inspection system deployment.

In summary, although challenges exist in implementing X-Ray inspection equipment for pet food quality assurance, advances in technology and thoughtful operational strategies can help overcome these hurdles. Selecting the right X-Ray inspection system and addressing these considerations will contribute to safer products and stronger market competitiveness.

Case Studies or Industry Examples

Real-world applications of X-Ray inspection systems in pet food manufacturing provide valuable insight into their effectiveness and return on investment. The following examples illustrate how leading brands and quality control teams are leveraging X-Ray inspection equipment to enhance product safety and operational efficiency.

Example of a Pet Food Brand Reducing Recalls Using X-Ray Inspection

A well-known premium pet food manufacturer experienced multiple product recalls due to undetected metal fragments from worn processing equipment. After implementing an advanced X-Ray inspection system across all production lines, the brand reported a significant drop in contamination incidents. The X-Ray inspection machines allowed the company to detect even the smallest metal shards embedded in kibble or sealed inside pouches—something their previous detection tools had missed. This shift not only protected consumers and pets but also safeguarded the brand’s reputation.

Comparison of Detection Rates Before and After System Installation

Another mid-sized pet food company conducted a six-month performance comparison before and after installing a new X-Ray inspection machine. Prior to the installation, their quality assurance relied solely on metal detectors and visual inspection, which had limited detection capabilities for non-metallic contaminants like bone or glass. Post-installation, the X-Ray inspection equipment demonstrated a 40% increase in foreign body detection rates, especially in products like freeze-dried meat treats and semi-moist foods packaged in multilayer films. The X-Ray inspection system’s ability to detect by density rather than material type proved essential for ensuring safer products.

Insights from Operators and QA Teams Using X-Ray Equipment

Feedback from frontline operators and quality assurance professionals highlights the day-to-day impact of X-Ray inspection systems. Operators appreciate the intuitive interfaces of modern X-Ray inspection machines, which simplify setup and calibration across various pet food formats. QA teams report greater confidence in contamination control thanks to automated rejection mechanisms and real-time imaging offered by the X-Ray inspection equipment. Many emphasize that X-Ray inspection systems provide unmatched consistency in detecting contaminants across a broad range of product types—dry kibble, canned foods, or freeze-dried treats—making them indispensable in modern pet food production environments.

Conclusion

In today’s competitive and highly regulated pet food industry, ensuring the highest level of product safety is not optional—it’s critical. X-Ray inspection systems offer unmatched precision and flexibility in detecting a wide range of contaminants that traditional methods may overlook. From metal fragments and bone shards to stones and dense plastics, modern X-Ray inspection equipment can detect foreign materials across various product forms and packaging types. Whether integrated early in the line or positioned at final packaging checkpoints, X-Ray inspection machines provide a robust layer of protection, supporting both food safety and brand integrity.

As pet owners become more discerning and regulations continue to tighten, the role of X-Ray inspection technology will only expand. The latest X-Ray inspection systems are evolving with smart features—AI-based detection, real-time auto-calibration, and cloud-based monitoring—to meet the growing complexity of pet food products. These intelligent X-Ray inspection machines are designed to adapt to variations in formulation, packaging, and presentation, ensuring consistent performance across changing product lines. With innovation accelerating, X-Ray inspection equipment will remain at the core of smart, data-driven quality assurance programs.

Adopting an X-Ray inspection system is not just about avoiding recalls or meeting compliance—it’s about delivering peace of mind to consumers who treat their pets like family. Manufacturers that invest in advanced X-Ray inspection equipment demonstrate a proactive commitment to quality, food safety, and transparency. By balancing operational efficiency with rigorous detection standards, brands can strengthen consumer trust and build long-term loyalty. In this era of heightened awareness and expectations, X-Ray inspection machines are not a luxury—they’re a necessity for any pet food producer striving to lead in both safety and sustainability.

FAQ

Q: Why is X-Ray inspection necessary in pet food production?

A: Pet food can contain contaminants like metal fragments, bone shards, or glass that are difficult to detect with traditional methods. X-Ray inspection systems can identify these foreign bodies based on density differences, ensuring the safety and quality of the final product.

Q: What types of pet food benefit most from X-Ray inspection systems?

A: All types—dry kibble, wet/canned food, freeze-dried treats, and semi-moist formulas—can benefit. X-Ray inspection equipment can detect contaminants hidden in both raw ingredients and final packaged products.

Q: Is X-Ray inspection equipment affordable for small and medium pet food producers?

A: Many X-Ray inspection system manufacturers offer scalable solutions tailored for SMEs. Though initial investment may be higher than metal detectors, the long-term ROI is often superior due to fewer recalls, reduced waste, and enhanced brand protection.