Introduction

In today’s highly competitive food and beverage industry, ensuring product purity is no longer a choice—it is a necessity. Consumers are increasingly demanding higher food quality, pushing manufacturers to adopt more advanced quality control technologies. For liquid and semi-liquid products like beverages and sauces, where contaminants may be difficult to detect using traditional methods, X-Ray inspection systems have become an essential line of defense.

Importance of Product Purity in Liquid and Semi-Liquid Food Products

Beverages and sauces, due to their flowable nature, can easily conceal foreign contaminants such as metal fragments, bone chips, or glass shards. Even the smallest impurity can compromise consumer health, brand reputation, and regulatory compliance. This makes product purity not just a matter of quality assurance, but of public safety. Food X-Ray inspection offers a powerful solution by enabling real-time, non-destructive detection of a wide range of contaminants within flowing liquids and semi-liquids during the production process.

Overview of Quality Challenges in Beverage and Sauce Production

Maintaining consistent food quality in the production of beverages and sauces presents several unique challenges. The opaque or dense nature of some sauces can interfere with visual or metal detection methods. In addition, high-speed production lines often leave little room for manual inspection, increasing the risk of undetected contamination. Temperature fluctuations, ingredient variations, and packaging inconsistencies can further complicate quality control. These challenges highlight the need for highly adaptable X-Ray inspection machines that can function reliably in dynamic production environments.

Role of Advanced Pipeline X-Ray Inspection System in Modern Food Manufacturing

Modern Pipeline X-Ray inspection systems are designed specifically to address these challenges. Installed directly into the processing pipeline, these systems use high-resolution imaging and advanced algorithms to detect a wide range of contaminants without interrupting the flow of product. Whether dealing with viscous sauces, dairy-based beverages, or fruit purees, this X-Ray inspection equipment delivers fast and accurate detection.

Unlike traditional detection methods, pipeline X-Ray inspection is not affected by product temperature, salt content, or moisture levels. This makes it ideal for maintaining consistent food quality across various product types. Moreover, the compact design of modern X-Ray inspection machines allows them to be seamlessly integrated into existing production lines, maximizing efficiency while reducing waste and recalls.

With the demand for safer, higher-quality liquid and semi-liquid food products at an all-time high, the integration of X-Ray inspection systems—especially pipeline variants—has become critical. They represent a future-ready solution for manufacturers seeking to elevate their standards of food X-Ray inspection and maintain consumer trust.

Challenges in Contaminant Detection for Liquids and Viscous Products

In the food and beverage industry, ensuring product integrity in liquids and viscous substances like sauces, dairy, purees, and syrups is a persistent challenge. These types of products are often opaque, dense, and flow through sealed pipelines, making traditional visual inspection methods ineffective. As a result, X-Ray inspection has emerged as a critical solution for maintaining high food quality standards.

Difficulties in Detecting Foreign Bodies in Opaque, Flowing Substances

One of the key challenges in liquid product inspection is that the contents cannot be visually observed during processing. Liquids and semi-liquids often have variable density, high turbidity, or are encased in thick packaging or piping systems that obscure direct observation. This makes the detection of foreign materials extremely difficult without advanced X-Ray inspection equipment. Unlike optical systems, an X-Ray inspection machine can penetrate opaque materials and accurately detect density variations, making it ideal for this application.

Pipeline X-Ray inspection systems are specifically engineered to monitor product flow in real time. These systems use high-resolution detectors to identify even the smallest anomalies inside a pipe, ensuring reliable and consistent food X-Ray inspection performance. This non-invasive technology allows manufacturers to identify contaminants at an early stage—before they reach the final packaging process.

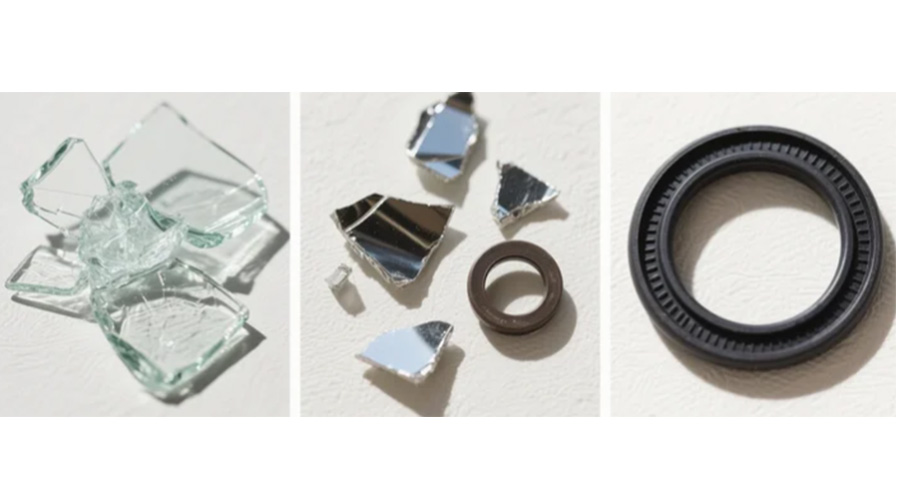

Common Contaminants in Pipelines: Metal Fragments, Glass, Bone, Rubber, etc.

Liquid and viscous food products are just as susceptible to contamination as solid foods. During production, foreign materials such as metal fragments, glass shards, bone chips, and rubber particles can enter the product stream through damaged equipment, faulty raw materials, or human error.

Standard sieving and filtration methods often fall short when it comes to microscopic or low-density contaminants. That’s where pipeline X-Ray inspection machines provide a superior solution. These systems are designed to identify both high-density contaminants like metal and glass, as well as more difficult-to-detect substances such as plastic or bone, without disrupting production flow. Their adaptability makes them essential for modern food X-Ray inspection processes across industries handling viscous or liquid-based products.

Risks of Undetected Contamination for Brands and Consumers

The consequences of undetected contamination can be severe. From costly product recalls to lasting brand damage and potential harm to consumers, the risks are substantial. A single foreign object in a bottle of juice or a jar of sauce can erode consumer trust and result in significant regulatory penalties.

By investing in a robust pipeline X-Ray inspection system, food manufacturers can reduce these risks and demonstrate a strong commitment to food quality and safety. This not only protects consumers but also enhances brand reputation and ensures compliance with food safety standards.

What Is Pipeline X-Ray Inspection Technology?

In the realm of food safety and quality assurance, pipeline X-Ray inspection technology stands out as a highly specialized solution tailored for liquid, semi-liquid, and paste-like products. This X-Ray inspection system is specifically designed to detect contaminants within closed pipelines—enabling real-time analysis during continuous processing without halting production or compromising throughput. As consumer demand for premium food quality continues to rise, ensuring product integrity with X-Ray inspection equipment is becoming an industry standard.

Working Principles of Pipeline X-Ray Systems

A pipeline X-Ray inspection machine operates by directing a focused X-ray beam through the flowing product inside a sanitary pipe. As the X-ays pass through the substance, a food X-Ray inspection detector measures the varying densities, identifying anomalies such as metal fragments, glass shards, or stones based on their radiographic properties. Unlike traditional detection technologies, X-Ray can identify both metallic and non-metallic contaminants—even in opaque, viscous substances like sauces, yogurts, and beverages. This capability makes X-Ray inspection a reliable tool in liquid product manufacturing.

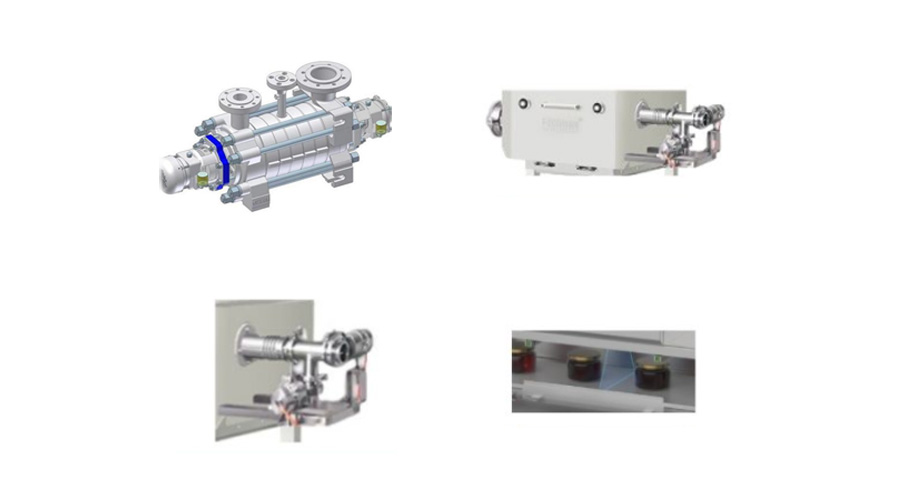

Key Components: Pump, Pipe, X-Ray Detection Chamber, and Rejection Valve

A complete X-Ray inspection system for pipelines consists of several critical components:

Sanitary pump: Ensures consistent and hygienic flow of the product through the system.

Pipe segment: Custom-designed for X-Ray transmission and food-safe operation.

X-Ray detection chamber: The heart of the X-Ray inspection equipment, where real-time scanning and analysis take place.

Rejection valve: Once a contaminant is identified, this automated valve removes the affected portion of the product from the flow—without halting the process.

These integrated parts allow the food X-Ray inspection system to maintain high sensitivity while minimizing waste and production downtime.

Integration into Continuous Production Lines

One of the biggest advantages of pipeline X-Ray inspection machines is their seamless integration into existing production lines. Whether in beverage bottling plants, sauce manufacturing, or dairy processing, these systems offer uninterrupted X-Ray inspection with automated rejection and data logging. This ensures that any foreign materials are caught before packaging, upholding both food quality and consumer trust.

With hygiene-compliant design, CIP (Clean-in-Place) compatibility, and customizable interfaces, pipeline X-Ray inspection systems have become indispensable assets in modern food manufacturing, meeting HACCP and global safety standards.

In summary, as producers seek to strengthen food quality and safety controls, pipeline X-Ray inspection technology provides a robust, precise, and efficient solution—capable of safeguarding both brands and consumers from the hidden dangers of contamination in liquid and viscous food products.

Advantages of Pipeline X-Ray for Beverages and Sauces

In the high-speed world of liquid food production, maintaining consistent food quality while ensuring safety is non-negotiable. That’s where pipeline X-Ray inspection systems come into play, offering unparalleled advantages for manufacturers of beverages, sauces, and other viscous products. These advanced X-Ray inspection machines are purpose-built to meet the unique demands of liquid product inspection — all without disrupting your flow.

Real-time, Non-Invasive Inspection Without Interrupting Flow

One of the most significant benefits of pipeline X-Ray inspection equipment is its ability to perform real-time analysis as the product moves through the line. Unlike traditional methods that require stops or sampling, pipeline X-Ray inspection systems are fully non-invasive. They scan for contaminants like metal shards, glass pieces, and bone fragments while the product remains sealed in hygienic pipes. This ensures uninterrupted production and enhances operational efficiency without compromising food quality.

High Detection Accuracy for a Variety of Contaminants

Modern food X-Ray inspection technology used in pipeline systems delivers high-sensitivity detection. Whether it’s stainless steel particles, dense plastic, or stones, these systems use dual-energy or high-resolution X-Ray inspection machines to identify foreign bodies that are otherwise invisible in opaque or dense liquids. This high detection capability significantly reduces the risk of contaminated batches reaching consumers, thereby protecting your brand and boosting consumer trust.

Hygienic, CIP (Clean-in-Place) Compatible Design

Hygiene is paramount in liquid food processing. Pipeline X-Ray inspection equipment is designed with sanitary, stainless-steel construction and is fully compatible with CIP (Clean-in-Place) protocols. This allows automated cleaning without disassembling the system, ensuring compliance with food safety standards while minimizing manual labor. The hygienic design not only improves safety but also supports consistent food quality over time.

Minimal Product Waste and Reduced Downtime

Conventional contaminant detection methods often result in large quantities of product being discarded. In contrast, a pipeline X-Ray inspection system allows for precise rejection, often diverting only a small contaminated portion. This level of accuracy reduces unnecessary product loss and helps manufacturers meet sustainability goals. Moreover, its continuous operation minimizes downtime, helping factories stay on schedule and maximize throughput.

Application Scenarios in Food Processing

Milk, Yogurt, Fruit Juice, and Other Beverages

Dairy and juice products are especially vulnerable to contamination during upstream processing. Whether it’s milk, yogurt, or fruit juice, maintaining purity is vital—not only for food quality, but also for consumer trust and brand reputation.

A pipeline X-Ray inspection machine allows continuous, real-time detection of contaminants such as glass shards, metal fragments, or rubber gaskets. The X-Ray inspection system is integrated directly into the production line and inspects the product as it flows through sealed pipes, ensuring hygienic and non-invasive testing without interrupting production. This makes it an ideal food X-Ray inspection solution for high-volume beverage production.

Tomato Paste, Soy Sauce, Salad Dressing, and Other Sauces

Viscous and opaque products like tomato paste, soy sauce, and salad dressings pose a unique challenge for visual or metal detection. Here, X-Ray inspection equipment excels by using density-based imaging that detects both metallic and non-metallic contaminants—even in dense, dark sauces.

The application of a pipeline X-Ray inspection system in sauce production helps catch hard-to-see contaminants such as bone fragments, pieces of plastic, or machine wear particles. These contaminants, if undetected, could lead to costly recalls or damaged brand image. By using food X-Ray inspection early in the process, manufacturers can confidently uphold product integrity and improve end-to-end food quality control.

Inspection Before Filling or Packaging to Ensure Final Product Safety

One of the greatest advantages of pipeline-based X-Ray inspection machines is their strategic placement before the filling and packaging stage. This timing ensures that only safe, contaminant-free product enters the final container, eliminating the risk of foreign objects reaching consumers.

Integrating X-Ray inspection systems at this critical control point helps reduce waste, prevent downtime, and meet global food safety standards. It is particularly valuable in HACCP-compliant environments, where food X-Ray inspection is recognized as an effective preventive measure.

Technological Innovations and AI Integration in Pipeline X-Ray Inspection Systems

In today’s fast-paced food processing industry, the demand for intelligent, accurate, and efficient inspection solutions is greater than ever. Pipeline X-Ray inspection systems are evolving rapidly, thanks to technological innovations and the integration of artificial intelligence (AI). These advancements not only enhance detection precision but also ensure compliance with strict food safety regulations.

Enhancing Detection Accuracy with AI

Modern X-Ray inspection equipment now leverages AI algorithms to significantly improve the detection of contaminants in liquid and semi-liquid food products. By learning from thousands of product images, AI-driven X-Ray inspection machines can distinguish between acceptable variations and actual foreign materials. This dramatically reduces false positives and helps maintain production efficiency while safeguarding food quality.

AI also enables real-time adjustments based on product characteristics, such as density, viscosity, and flow rate. This ensures that the food X-Ray inspection process remains highly accurate and adaptable to different product types, whether it’s milk, yogurt, or thick sauces.

Data Logging and Traceability

Another key innovation in X-Ray inspection systems is the incorporation of comprehensive data logging and traceability features. Every inspected batch can be tracked with detailed logs, including timestamps, product settings, detection results, and even rejection events. This level of traceability supports food manufacturers in meeting HACCP requirements and other global food safety standards.

By storing inspection data digitally, X-Ray inspection machines also simplify quality audits and enable long-term performance monitoring, which contributes to continuous improvement of food quality control processes.

Smart Monitoring and Remote Diagnostics

Smart monitoring technologies are transforming how food manufacturers manage X-Ray inspection machines. With cloud-based dashboards and real-time alerts, operators can monitor system performance and contamination events from anywhere. Remote diagnostics further reduce downtime by allowing technical support teams to troubleshoot X-Ray inspection equipment without the need for on-site visits.

These capabilities make modern food X-Ray inspection solutions not only more intelligent but also more reliable and user-friendly, reinforcing both operational efficiency and product safety.

Selection Tips for Pipeline X-Ray Systems in Food Processing

Choosing the right X-Ray inspection system for pipeline applications is essential for maintaining high food quality and meeting safety regulations. Whether you’re processing dairy, beverages, or sauces, selecting the optimal X-Ray inspection machine ensures accurate contaminant detection without disrupting the production line. Here are key considerations to help food manufacturers make an informed decision.

Flow Rate, Viscosity, Pipe Diameter, and Line Pressure

The first step in selecting a pipeline X-Ray inspection system is evaluating your product’s physical properties and processing environment. The flow rate and viscosity of liquids like milk, fruit juice, or tomato paste significantly influence inspection performance. Thick, high-viscosity products may require more sensitive X-Ray inspection equipment to ensure contaminants like metal fragments or glass shards are identified.

Similarly, the pipe diameter and line pressure affect the compatibility and efficiency of the system. Choosing a machine with customizable pipe fittings and pressure-resilient design is essential for seamless integration and stable performance.

Importance of Hygiene Standards and Maintenance Accessibility

In the food industry, hygiene is non-negotiable. The ideal food X-Ray inspection solution must be built for clean-in-place (CIP) processes, enabling efficient sanitation without dismantling the unit. Stainless steel construction, smooth surfaces, and minimal dead zones are key features that reduce contamination risk.

Additionally, accessibility for maintenance and cleaning plays a major role. A well-designed X-Ray inspection machine minimizes downtime by allowing fast part replacement and easy visual inspection, helping processors uphold strict hygiene and food quality standards.

Matching the Machine to Your Production Scale and Product Type

Not all X-Ray inspection systems are created equal. Manufacturers need to assess their production scale and the specific types of products being processed. High-speed beverage lines require machines that can perform real-time, high-throughput scanning, while slower sauce lines may benefit from higher-resolution imaging for denser products.

Customization options in X-Ray inspection equipment, such as adjustable detection thresholds and dual-energy imaging, allow better adaptation to varied production needs. Working with a provider who offers application-specific solutions and after-sales support ensures your inspection system evolves with your product line.

Conclusion

Summary of Benefits for Food and Beverage Producers

Pipeline X-Ray inspection systems offer substantial benefits to food and beverage producers aiming to safeguard food quality and ensure consumer safety. By detecting contaminants such as metal fragments, glass, and bone in real time, this X-Ray inspection equipment minimizes the risk of product recalls and brand damage. The integration of X-Ray inspection machines into continuous production lines helps maintain high throughput while delivering accurate, non-invasive inspection—key advantages for modern food manufacturers focused on efficiency and compliance.

Pipeline X-Ray as a Critical Step Toward Zero-Defect Production

In the pursuit of zero-defect production, pipeline food X-Ray inspection plays a critical role by enabling continuous monitoring of liquid and semi-liquid products without interrupting the manufacturing process. These X-Ray inspection systems help eliminate foreign bodies before products reach packaging, ensuring final products meet stringent safety standards. The precision and reliability of this X-Ray inspection equipment make it indispensable in achieving defect-free food production, reducing waste, and boosting overall product consistency.

Future Outlook for Smart, Automated Inspection Systems in Fluid Food Processing

Looking forward, the future of pipeline X-Ray inspection in fluid food processing is defined by smarter, more automated systems. Integration of AI and machine learning technologies will enhance detection accuracy, reduce false positives, and improve decision-making processes. Advanced data logging and remote diagnostics will facilitate better traceability and predictive maintenance, helping food manufacturers stay ahead of regulatory requirements. As these innovations mature, X-Ray inspection machines will become increasingly essential in supporting sustainable, safe, and efficient food production lines.

FAQ

Q: What factors should be considered when choosing an X-Ray inspection machine for liquid products?

A: Consider flow rate, product viscosity, pipe diameter, line pressure, hygiene standards, and your production capacity to ensure optimal equipment performance.

Q: What is a pipeline X-Ray inspection system?

A: A pipeline X-Ray inspection system is a type of X-Ray inspection equipment designed to detect contaminants in pumped liquid or semi-liquid food products such as sauces, beverages, and dairy.

Q: How does AI integration improve X-Ray inspection systems?

A: AI algorithms reduce false positives, improve detection accuracy, and enable smart self-diagnosis for continuous, reliable food quality control.