Introduction

Explanation of Detection Blind Spots in X-Ray Inspection Systems

Detection blind spots in X-Ray inspection systems refer to areas within the product or packaging that remain unscanned or poorly imaged due to limitations in the X-Ray beam’s angle or positioning. These blind spots can occur when the X-Ray inspection machine’s imaging angle fails to fully penetrate complex product shapes, dense packaging

materials, or overlapping components. As a result, contaminants or defects hidden within these blind spots may go undetected, posing a significant risk to product quality and safety.

Why Blind Spots Pose a Critical Challenge in Food and Pharmaceutical Quality Control

In industries such as food and pharmaceuticals, maintaining stringent quality control is paramount. Food X-Ray inspection equipment is relied upon to detect foreign objects like metal fragments, glass shards, bone pieces, and other contaminants that could endanger consumers. Similarly, pharmaceutical manufacturers depend on X-Ray inspection machines to verify tablet integrity, blister pack completeness, and contaminant absence.

Blind spots within the inspection process undermine these safety measures by creating gaps where contaminants can evade detection. Such oversights can lead to product recalls, regulatory penalties, and, most importantly, risks to consumer health. Therefore, eliminating or minimizing blind spots is a critical challenge that must be addressed to ensure the reliability and effectiveness of X-Ray inspection systems.

The Importance of Optimizing Image Angles to Improve Detection Accuracy

Optimizing image angles in X-Ray inspection equipment is essential to overcoming detection blind spots. By adjusting the angle of the X-Ray beam or employing multi-angle imaging techniques, manufacturers can achieve more comprehensive product coverage. This enhanced imaging approach allows X-Ray inspection machines to capture detailed views from different perspectives, revealing hidden contaminants or defects that might be missed with a single-angle scan.

Moreover, optimizing image angles not only improves detection accuracy but also reduces false negatives, thereby enhancing overall inspection confidence. For food X-Ray inspection and pharmaceutical quality control alike, leveraging advanced imaging angle strategies in X-Ray inspection systems is a vital step toward ensuring safer products and maintaining compliance with industry standards.

Understanding Detection Blind Spots

Definition and Causes of Blind Spots in X-Ray Inspection

Detection blind spots in X-Ray inspection refer to areas within a product or packaging that the X-Ray beam fails to adequately scan or visualize. These blind spots occur due to limitations in the angle or positioning of the X-Ray source and detector, which can result in incomplete imaging of certain product features. In many cases, the geometry of the product or the density of packaging materials can obstruct the X-Ray beam, preventing the X-Ray inspection machine from capturing a full, detailed image.

Other causes include the use of single-angle scanning in some X-Ray inspection systems, where only one perspective is used to inspect products. This can lead to parts of the product being hidden behind denser areas or packaging components, creating shadows or areas with insufficient data, known as blind spots.

Common Scenarios Where Blind Spots Occur

Blind spots frequently arise in food X-Ray inspection when inspecting products with complex shapes or uneven surfaces, such as irregularly shaped meats, layered snacks, or products with dense packaging materials like foil or plastic films. Similarly, in pharmaceutical production, blister packs or bottles with irregularly shaped contents may create areas that are difficult to image thoroughly with a single-angle X-Ray inspection machine.

Packaging designs that use multiple layers or contain materials with different densities can further complicate X-Ray imaging. For example, overlapping packaging seams, desiccants, or multilayer foil can cause certain regions to appear opaque, increasing the likelihood of blind spots during inspection.

Impact of Blind Spots on Contaminant Detection and Overall Inspection Reliability

The presence of blind spots significantly undermines the effectiveness of any food X-Ray inspection system. Contaminants such as metal fragments, glass shards, or bone pieces can remain hidden within these unscanned regions, leading to false negatives where unsafe products pass through inspection undetected.

This not only poses safety risks to consumers but also affects brand reputation and can result in costly recalls. For pharmaceutical products, undetected defects or missing components due to blind spots can jeopardize product efficacy and regulatory compliance.

Overall, blind spots reduce the reliability of X-Ray inspection machines and increase the challenge of maintaining consistent quality control. Addressing these blind spots through optimized imaging angles and advanced inspection equipment is therefore critical to enhancing detection accuracy and ensuring the highest level of product safety.

Role of Image Angles in X-Ray Inspection

How X-Ray Imaging Geometry Affects Detection Coverage

The geometry of X-Ray imaging plays a crucial role in determining the coverage and effectiveness of an X-Ray inspection system. In X-Ray inspection, the angle at which the X-Ray beam passes through the product directly influences the visibility of internal structures and potential contaminants. If the beam is aligned in a way that parts of the product are obscured by dense materials or packaging, certain areas become blind spots where defects can hide.

Optimizing the imaging geometry means positioning the X-Ray source and detectors to maximize the scanned area and minimize hidden zones. This ensures that the X-Ray inspection machine can capture detailed images from angles that reveal contaminants which might otherwise remain undetected.

Single-Angle Versus Multi-Angle X-Ray Inspection Approaches

Traditional X-Ray inspection equipment often relies on a single-angle approach, where the X-Ray beam passes through the product in one fixed direction. While simpler and less expensive, this method increases the risk of blind spots because it cannot visualize parts of the product obscured by other materials or complex shapes.

In contrast, multi-angle X-Ray inspection systems use multiple X-Ray sources and detectors arranged around the product to scan from different perspectives. This technique significantly reduces blind spots by providing comprehensive imaging coverage. Multi-angle approaches enable more reliable detection of foreign objects, irregularities, and packaging defects in food and pharmaceutical products.

Advantages of Optimizing Image Angles to Minimize Blind Spots

Optimizing image angles in food X-Ray inspection machines offers several key advantages:

Improved Contaminant Detection: Multiple viewing angles increase the likelihood of detecting small or low-contrast foreign bodies hidden within dense or layered packaging.

Enhanced Product Integrity Analysis: Different perspectives allow inspection of product fill levels, shape consistency, and structural integrity more accurately.

Reduced False Negatives: By minimizing blind spots, optimized image angles reduce the risk of missing defects, which enhances overall inspection reliability.

Better Adaptability: Optimized X-Ray inspection systems can handle a wider variety of product shapes, sizes, and packaging types, improving operational flexibility.

Incorporating optimized imaging angles into X-Ray inspection equipment design ensures a higher level of quality control, especially in complex multi-lane production lines where product variability is common.

Technologies for Optimizing Image Angles

Multi-Angle X-Ray Inspection Machines: Overview and Benefits

Modern X-Ray inspection machines increasingly incorporate multi-angle imaging technology to overcome the limitations of traditional single-angle systems. Multi-angle X-Ray inspection equipment uses multiple X-Ray sources and detectors arranged strategically around the product, enabling simultaneous imaging from different directions. This comprehensive approach dramatically reduces detection blind spots and enhances overall inspection accuracy.

For food X-Ray inspection, multi-angle systems are particularly valuable, as they can detect foreign objects hidden behind dense packaging layers or irregularly shaped products. This technology not only improves contaminant detection but also increases throughput efficiency by minimizing the need for re-inspections and manual checks.

Rotational and Multi-View Imaging Techniques

Rotational and multi-view imaging are two advanced techniques used in cutting-edge X-Ray inspection systems to optimize image angles:

Rotational Imaging: Involves rotating either the product or the X-Ray source/detector assembly to capture multiple images from various angles. This dynamic method provides a 360-degree view of the product, revealing contaminants or defects that might be invisible in static scans.

Multi-View Imaging: Uses fixed multiple detectors positioned around the product to capture simultaneous images from different perspectives without requiring rotation. This approach is especially effective in high-speed food production lines where continuous motion limits rotation possibilities.

Both techniques enhance the X-Ray inspection machine’s ability to identify hidden defects, improving quality control in food and pharmaceutical manufacturing.

Advanced Detector Positioning and Beam Shaping for Angle Optimization

Beyond imaging techniques, optimizing the physical arrangement of detectors and X-Ray beams is critical for maximizing inspection coverage. Advanced X-Ray inspection equipment utilizes precise detector positioning and beam shaping technologies to focus the X-Ray energy on critical product areas while reducing overlap and signal interference between angles.

Beam shaping involves adjusting the X-Ray beam’s geometry—such as its width and intensity distribution—to ensure optimal penetration and contrast across different product regions. Meanwhile, dynamic detector arrays can be configured to align perfectly with product contours, enabling sharper image resolution and more accurate defect identification.

Together, these innovations in detector positioning and beam shaping elevate the performance of X-Ray inspection systems, making them indispensable tools in modern food X-Ray inspection and pharmaceutical quality assurance.

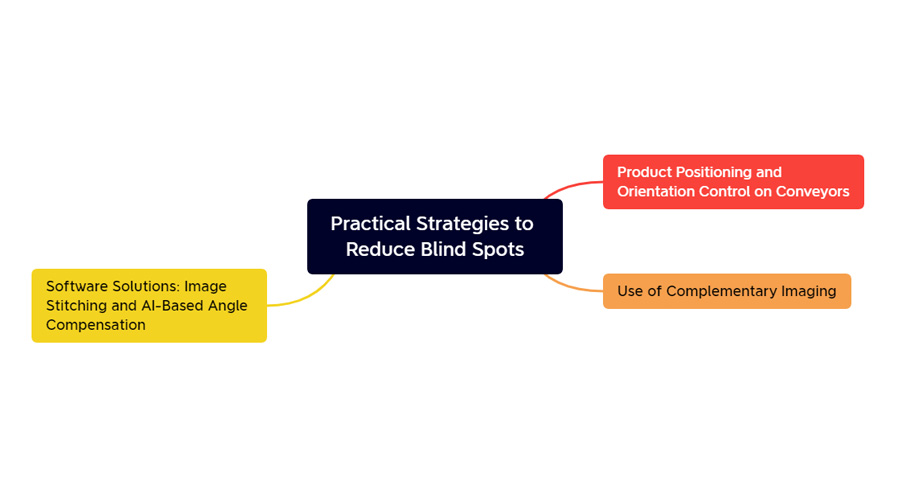

Practical Strategies to Reduce Blind Spots

Product Positioning and Orientation Control on Conveyors

One of the most effective ways to minimize detection blind spots in X-Ray inspection systems is by controlling the positioning and orientation of products on the conveyor belt. Proper alignment ensures that the X-Ray inspection machine receives optimal views of each item, maximizing the chance of identifying hidden contaminants.

In food X-Ray inspection lines, specialized conveyor designs with guides or lane dividers help maintain consistent product orientation and spacing. This controlled movement reduces the likelihood of overlapping items and uneven scanning, which are common causes of blind spots. By combining mechanical solutions with smart X-Ray inspection equipment, manufacturers can enhance the overall accuracy and reliability of their quality control processes.

Use of Complementary Imaging

Complementary imaging techniques provide additional visual perspectives that help cover blind spots left by traditional X-Ray inspection machines. For instance, combining X-Ray inspection with visible light cameras or infrared imaging can reveal surface-level defects or packaging irregularities that might not appear clearly in X-Ray images alone.

Some advanced food X-Ray inspection systems integrate multi-sensor technologies, enabling simultaneous acquisition of different image types. This fusion of data allows for more comprehensive product analysis and a higher confidence level in defect detection. Complementary imaging acts as an essential layer of defense, especially in complex products where contaminants could be obscured by packaging or product geometry.

Software Solutions: Image Stitching and AI-Based Angle Compensation

Modern X-Ray inspection equipment leverages sophisticated software algorithms to further reduce blind spots. Image stitching technology combines multiple X-Ray images taken from different angles into a single, high-resolution composite, providing a holistic view of the product. This approach enhances defect visibility by filling in gaps caused by individual scan limitations.

AI-based angle compensation algorithms also play a crucial role by dynamically adjusting detection parameters based on product orientation and movement. These intelligent systems can predict and correct potential blind spots in real time, improving inspection sensitivity without increasing false positives.

Together, image stitching and AI-driven compensation empower X-Ray inspection systems to deliver superior accuracy and efficiency in food X-Ray inspection, supporting manufacturers in meeting stringent safety and quality standards.

Case Studies: Improved Detection Through Angle Optimization

Food Industry Examples

In the food industry, optimizing image angles in X-Ray inspection systems has led to significant improvements in detecting hidden contaminants. For example, X-Ray inspection machines used in meat processing can more accurately identify tiny bone fragments that often go unnoticed due to product shape and density variations. Similarly, in packaged snacks, optimized imaging angles help reveal foreign objects like plastic pieces or metal shards that may be concealed by complex packaging layers.

These enhancements in food X-Ray inspection not only boost safety but also reduce costly recalls and brand damage. Manufacturers report fewer missed contaminants and enhanced confidence in product quality, thanks to the advanced X-Ray inspection equipment designed with multi-angle imaging capabilities.

Pharmaceutical Inspection: Blister Packs and Tablet Detection Improvements

Pharmaceutical manufacturers also benefit from angle-optimized X-Ray inspection systems. Blister packs and tablet lines are particularly challenging due to reflective packaging and varying product densities. Multi-angle X-Ray inspection machines can capture different views of blister packs, ensuring that missing tablets, broken pills, or foreign particles are detected reliably.

With precise beam positioning and intelligent image processing, these X-Ray inspection machines provide a comprehensive analysis of pharmaceutical products. This leads to better compliance with strict regulatory standards and enhanced patient safety, reinforcing the critical role of X-Ray inspection equipment in pharmaceutical quality control.

Quantitative Results Showing Reduced False Negatives and Improved Detection Rates

Numerous case studies demonstrate the measurable impact of angle optimization on detection accuracy. Companies implementing multi-angle X-Ray inspection systems have reported reductions in false negatives by up to 40%, ensuring fewer contaminated products reach consumers. Detection rates of small or low-density foreign objects have also improved significantly, sometimes exceeding 95% accuracy.

These quantitative results underscore the importance of optimizing image angles in food X-Ray inspection and pharmaceutical applications. By integrating advanced X-Ray inspection equipment with sophisticated imaging techniques, manufacturers achieve higher quality assurance levels and operational efficiency, ultimately safeguarding public health and brand reputation.

Challenges and Considerations

Balancing Complexity, Cost, and Throughput When Adding Multiple Imaging Angles

While optimizing image angles significantly enhances detection accuracy, incorporating multi-angle imaging into X-Ray inspection systems introduces additional complexity. Advanced X-Ray inspection machines with multiple detectors and rotational capabilities tend to increase equipment costs and require more sophisticated controls. Manufacturers must carefully balance these costs against the benefits of improved contaminant detection.

Moreover, adding multiple imaging angles can impact throughput, as capturing and processing more images per product may slow down the inspection process if not managed properly. Therefore, designing X-Ray inspection equipment that maintains high-speed operation while delivering multi-angle data is crucial, especially in fast-paced food X-Ray inspection lines.

Integration with Existing X-Ray Inspection Equipment and Production Lines

Integrating angle-optimized X-Ray inspection systems into existing production environments can pose challenges. Compatibility with current conveyor setups, synchronization with upstream and downstream equipment, and space constraints are key factors to consider.

Retrofitting existing X-Ray inspection machines with multi-angle capabilities may require hardware upgrades or software enhancements. Manufacturers should ensure that new X-Ray inspection equipment can seamlessly interface with their production control systems to avoid disruptions and maintain efficient workflows.

Training and Maintenance Requirements for Advanced Angle-Optimized Systems

Advanced X-Ray inspection machines featuring angle optimization demand specialized training for operators and maintenance staff. Understanding how to adjust imaging parameters, interpret multi-angle images, and troubleshoot complex hardware configurations is essential for maximizing system performance.

Routine maintenance may also be more involved, as multiple detectors and moving parts require precise calibration and regular servicing. Investing in comprehensive training programs and establishing clear maintenance protocols ensures that food X-Ray inspection equipment operates reliably over its service life.

Future Trends in Image Angle Optimization

AI-Driven Adaptive Imaging and Dynamic Angle Adjustment

The future of X-Ray inspection systems lies in intelligent, AI-driven adaptive imaging. Advanced X-Ray inspection machines are increasingly equipped with AI algorithms capable of dynamically adjusting imaging angles in real time based on product characteristics and detected anomalies. This dynamic angle adjustment enhances the food X-Ray inspection process by minimizing blind spots without manual intervention, improving contaminant detection accuracy across diverse product types and packaging styles. Such adaptive systems help manufacturers maintain high throughput while ensuring product safety.

Integration with Robotics for Product Manipulation and Enhanced Imaging

Robotic integration represents a significant innovation in optimizing image angles within X-Ray inspection equipment. By combining robotics with X-Ray inspection machines, products can be precisely manipulated or rotated before scanning to expose hard-to-see areas. This approach allows multi-angle imaging without adding multiple detectors or complex beam paths. For food X-Ray inspection, robotic handling enables more thorough analysis of irregularly shaped items, such as meat cuts or complex packaging, thereby improving inspection reliability and reducing false negatives.

Emerging Innovations in Detector Technology and Real-Time Image Fusion

Emerging detector technologies are pushing the boundaries of what X-Ray inspection systems can achieve in angle optimization. New high-sensitivity detectors with faster response times enable multi-angle data capture without compromising inspection speed. Additionally, real-time image fusion techniques combine data from different angles to create a comprehensive 3D representation of each product. This fusion enhances the detection of subtle contaminants and structural anomalies in food X-Ray inspection equipment, further reducing blind spots and improving overall accuracy. As these innovations mature, they will drive next-generation X-Ray inspection machines toward unprecedented levels of precision and efficiency.

Conclusion

Recap of the Importance of Overcoming Blind Spots through Optimized Image Angles

Detection blind spots remain a critical challenge in achieving comprehensive contaminant identification within X-Ray inspection systems. Optimizing image angles is a proven strategy to minimize these blind spots, ensuring that the X-Ray inspection machine captures every possible perspective of the product. For food X-Ray inspection and pharmaceutical quality control, this enhancement directly translates into higher detection accuracy and fewer missed defects, reinforcing product safety and consumer confidence.

How Manufacturers Can Improve X-Ray Inspection Accuracy and Product Safety

Manufacturers looking to elevate their inspection capabilities should focus on integrating advanced X-Ray inspection equipment that supports multi-angle imaging, intelligent image processing, and adaptable system configurations. By carefully selecting X-Ray inspection systems equipped with dynamic angle optimization and AI-driven analysis, companies can improve contaminant detection rates and reduce false negatives. These improvements not only safeguard product quality but also increase production efficiency, aligning with stringent regulatory standards in the food and pharmaceutical industries.

Final Thoughts on Selecting and Implementing Angle-Optimized X-Ray Inspection Equipment

When choosing an X-Ray inspection machine for complex production environments, prioritizing angle optimization features is essential. Factors such as detector technology, imaging geometry, and software capabilities should be thoroughly evaluated to ensure the system can effectively reduce blind spots while maintaining high throughput. Additionally, seamless integration with existing production lines and ease of maintenance are crucial for long-term operational success. Ultimately, investing in sophisticated, angle-optimized X-Ray inspection equipment empowers manufacturers to achieve unparalleled quality control and meet the evolving demands of modern food X-Ray inspection and pharmaceutical safety protocols.

FAQ

Q: Why is high accuracy important in multi-lane X-Ray inspection systems?

A: High accuracy ensures each product in every lane is individually inspected for contaminants, defects, or weight issues, preventing recalls and improving product safety.

Q: What challenges do X-Ray inspection systems face in multi-lane production lines?

A: Key challenges include image overlap between lanes, precise lane differentiation, real-time data processing, and maintaining consistent detection performance across all lanes.

Q: How do X-Ray inspection systems achieve lane separation during inspection?

A: Advanced systems use high-resolution imaging, AI-based image segmentation, and synchronized scanning to identify and isolate products in each lane with high precision.