Introduction

Brief Overview of the Importance of Fat Content in Meat Quality Control

In the meat industry, fat content plays a crucial role in determining overall product quality, taste, texture, and nutritional value. Precise fat analysis ensures that meat products meet both regulatory requirements and customer expectations. Inconsistent fat levels can affect grading, shelf life, and consumer satisfaction. This is why many producers are adopting advanced food X-Ray inspection solutions to achieve higher accuracy in fat measurement.

Rising Consumer Demand for Healthier, Consistent Meat Products

Today’s consumers are more health-conscious and demand transparency in food production. They want leaner, more consistent meat products without compromising taste. This shift in demand pushes meat processors to maintain strict fat-to-lean ratios while ensuring product uniformity. Traditional testing methods often fall short, but modern X-Ray inspection systems allow producers to monitor fat content in real time, helping them meet these growing expectations.

Introduction to Fat Analysis X-Ray Inspection System as a Solution

The Fat Analysis X-Ray Inspection System is an advanced quality control tool designed for the meat industry. Using dual-energy technology, this X-Ray inspection equipment can accurately differentiate between fat and lean meat, providing precise data without damaging the product. Unlike traditional sampling, the X-Ray inspection machine operates inline, offering continuous monitoring and reducing waste. By integrating food X-Ray inspection into production lines, meat producers can consistently meet quality standards, optimize yield, and ensure customer satisfaction.

Why Fat Content Matters in Meat Processing

Impact on Taste, Texture, And Nutritional Value

Fat content is one of the most critical factors determining the sensory qualities of meat, including flavor, juiciness, and mouthfeel. It plays a key role in how meat reacts during cooking, influencing tenderness and the release of savory aromas. Too much fat can lead to an overly greasy texture and excessive shrinkage during cooking, while too little can cause dryness, toughness, and reduced taste appeal. From a nutritional standpoint, maintaining the right fat-to-lean ratio is essential to meet consumer expectations for healthier, more balanced protein options.

With the rise of food X-Ray inspection technologies, processors can achieve precise fat analysis without damaging the product. By leveraging modern X-Ray inspection systems, meat producers can measure fat content in real-time, ensuring consistent product quality across batches. This data-driven approach not only enhances flavor and texture but also helps maintain brand reputation for delivering high-quality, uniform meat products.

Economic Influence: Pricing and Grading Based on Fat Percentage

In the competitive meat industry, fat percentage directly affects product classification, grading, and market value. Cuts with an ideal fat distribution are more desirable to both retailers and consumers, often commanding higher prices. On the other hand, products with uneven or excessive fat content risk being downgraded or sold at a lower price, impacting overall profitability.

Integrating X-Ray inspection machines with advanced fat analysis capabilities enables processors to optimize yield by reducing unnecessary trimming and improving portion accuracy. With X-Ray inspection equipment, production lines can detect variations in fat content instantly, making it easier to adjust processing steps and ensure each cut meets precise specifications. This translates into reduced waste, better resource utilization, and higher profit margins for meat producers.

Compliance with National and International Meat Quality Standards

Global meat markets operate under strict quality control regulations, with fat content often being a key compliance parameter. Export requirements in particular can be stringent, with allowable fat percentages differing between countries. Failure to meet these standards can result in rejected shipments, fines, or long-term damage to a company’s reputation.

X-Ray inspection systems with built-in fat analysis capabilities offer a reliable, automated solution for meeting these requirements. Unlike traditional manual sampling, which only tests a small portion of the batch, these systems perform 100% inline inspection, ensuring every single piece of meat is evaluated before leaving the facility. The integration of food X-Ray inspection equipment allows producers to generate detailed, verifiable reports that can be shared with regulators and customers, building trust and facilitating smoother export processes. In an era where transparency and accountability are vital, such technology not only safeguards compliance but also strengthens market competitiveness.

Challenges in Traditional Fat Analysis Methods

Time-Consuming Laboratory Testing

Traditional fat analysis in meat processing has long depended on sending samples to off-site or in-house laboratories for chemical or physical testing. While these methods are generally accurate, they often require sample preparation, specialized equipment, and trained personnel. This process can take several hours or even days before results are available, which is far from ideal for modern high-throughput production lines. In large-scale operations producing thousands of kilograms of meat daily, such delays can cause production bottlenecks, increase storage costs, and slow product release.

In contrast, food X-Ray inspection and modern X-Ray inspection systems with integrated fat analysis capabilities deliver results in seconds. This allows producers to monitor fat content continuously, make informed decisions instantly, and maintain a steady production flow without compromising on quality or compliance. The difference in turnaround time can mean the difference between meeting tight delivery schedules and facing costly delays.

Sampling Errors and Inconsistency

Manual sampling typically involves selecting a few pieces from a production batch and sending them for testing. However, fat distribution in meat is rarely uniform — one section of a carcass or cut may have significantly more fat than another. As a result, relying solely on a handful of samples introduces a high risk of sampling bias. Products that pass the test might not represent the true quality of the entire batch, potentially leading to inconsistent quality in the marketplace.

X-Ray inspection machines address this challenge by enabling 100% inline inspection of every product passing through the production line. Using advanced imaging and X-Ray inspection equipment, processors can capture detailed, real-time measurements of fat-to-lean ratios across all units, ensuring consistent quality. This not only reduces the risk of sending non-compliant products to customers but also strengthens brand reputation by delivering the same high standard every time.

Inability to Provide Real-Time Feedback During Production

One of the most significant drawbacks of traditional fat analysis methods is the lack of immediate feedback to operators. Without real-time data, production teams are essentially “working blind” — any deviation in fat content may go unnoticed until the batch has already been processed, packaged, or shipped. This delay often results in expensive rework, product recalls, or wasted raw materials.

By integrating X-Ray inspection systems equipped with advanced fat analysis software, meat processors can see fat distribution data instantly as products move along the conveyor. This enables immediate corrective actions, such as adjusting trimming processes, modifying grinding ratios, or diverting out-of-spec products before they reach packaging. Such proactive control reduces waste, increases yield, and ensures that every product leaving the facility complies with both internal quality requirements and stringent national or international standards.

How the Fat Analysis X-Ray Inspection System Works

Principle of Dual-Energy X-Ray Technology

The Fat Analysis X-Ray Inspection System operates on the principle of dual-energy X-ray technology, a proven method that uses two distinct X-ray energy levels to analyze the internal composition of meat with exceptional precision. This approach takes advantage of the fact that fat and lean meat absorb X-rays differently due to variations in density and chemical composition. By capturing images at both high and low energy levels, the X-Ray inspection machine generates a detailed map of the meat’s structure and calculates precise fat-to-lean ratios without the need for cutting, sampling, or destroying the product.

In addition, modern food X-Ray inspection systems equipped with dual-energy technology are capable of adjusting automatically to different meat types and sizes, ensuring accuracy whether scanning whole cuts, ground meat, or processed products. This adaptability allows processors to maintain a consistently high standard of quality across diverse product lines, even when production demands change rapidly.

How It Differentiates Fat from Lean Meat Using Density and Absorption Rates

Fat and lean muscle tissue have distinct physical properties, most notably in density and atomic composition, which directly affect how they absorb X-ray energy. The X-Ray inspection system uses sophisticated imaging algorithms to detect and compare these differences in absorption rates, creating a high-resolution profile of each product’s fat distribution.

This process enables extremely accurate fat analysis, even when working with irregularly shaped cuts, mixed batches, or products with complex internal structures. Whether deploying a standalone X-Ray inspection machine for a single production line or integrating X-Ray inspection equipment into a multi-line facility, processors can ensure every product meets target fat specifications. The result is not only improved product uniformity but also increased consumer confidence, as customers receive the same quality with every purchase.

Inline, Non-destructive, And High-Speed Measurement Capabilities

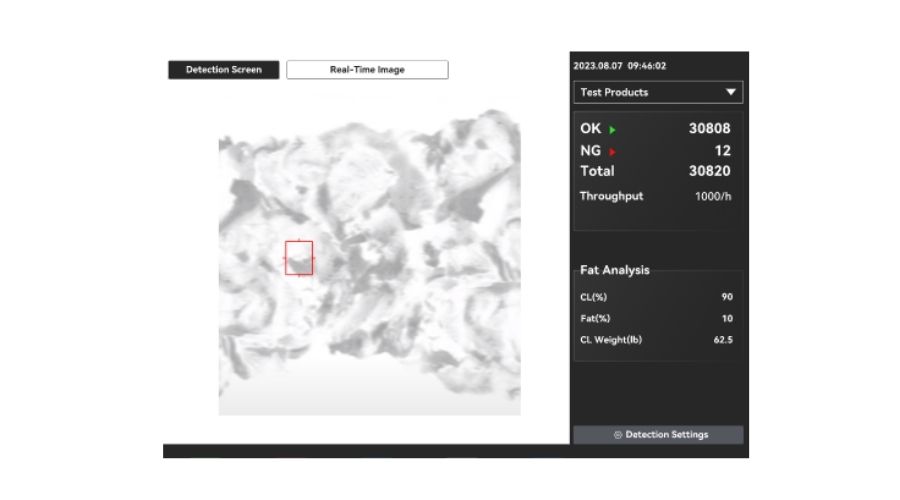

One of the most significant advantages of the Fat Analysis X-Ray Inspection System is its ability to carry out inline, non-destructive testing without interrupting workflow. Unlike conventional lab methods, which require taking physical samples and waiting for results, this system scans every item as it moves along the production line, capturing precise fat measurements in real time.

Advanced food X-Ray inspection equipment can handle hundreds or even thousands of products per hour while maintaining exceptional accuracy. This capability is crucial for large-scale meat processors who must balance high throughput with strict quality control.

By providing instant feedback, the X-Ray inspection system allows production teams to make on-the-fly adjustments to trimming, portioning, or blending processes, reducing waste and preventing costly rework. Over time, this results in higher operational efficiency, better yield management, and a stronger competitive edge in both domestic and international markets.

Applications Across the Meat Industry

Beef: Grading Carcasses and Primal Cuts

In the beef industry, accurate fat content measurement is essential for grading carcasses and primal cuts. Variations in marbling and fat distribution can affect both product quality and market price. Using a Fat Analysis X-Ray Inspection System, processors can perform food X-Ray inspection directly on the production line, capturing precise fat-to-lean ratios without destructive sampling. Advanced X-Ray inspection machines and X-Ray inspection equipment enable real-time analysis of each cut, ensuring consistency across batches and helping meet regulatory and customer standards.

Pork: Controlling Fat-to-Lean Ratio in Processed Products

For pork processing, controlling the fat-to-lean ratio in items such as sausages, bacon, and ham is crucial to maintain both taste and texture. Traditional methods rely on manual sampling, which is prone to inconsistencies. X-Ray inspection systems with integrated fat analysis capabilities provide rapid, inline measurement of fat content, minimizing deviations and ensuring uniform product quality. X-Ray inspection equipment can detect subtle variations in fat distribution, allowing producers to optimize formulations and maintain high yield efficiency.

Poultry: Ensuring Consistent Fat Levels in Chicken Parts

In poultry processing, consistent fat content in chicken breast, wings, and drumsticks is important for both consumer satisfaction and compliance with nutritional labeling. Food X-Ray inspection using dual-energy X-Ray inspection machines allows processors to measure fat distribution in real time. The X-Ray inspection system identifies even small variations in fat content, enabling adjustments to portioning or trimming. By implementing this technology, poultry processors can achieve consistent product quality, reduce waste, and streamline their production lines.

Seafood: Fat Measurement in High-Value Species like Salmon

High-value seafood products such as salmon and trout require precise fat measurement to meet market expectations and pricing standards. Fat analysis via X-Ray inspection systems offers a non-destructive, high-speed solution for monitoring fat content in fillets and whole fish. Advanced X-Ray inspection equipment ensures accurate inline measurement, helping producers deliver consistent texture and flavor. Integrating food X-Ray inspection machines into seafood processing lines also improves traceability and compliance, allowing processors to verify fat levels for both domestic and international markets.

Meeting Quality Standards with X-Ray Technology

How Real-Time Fat Analysis Ensures Compliance with Regulatory Limits

Maintaining compliance with national and international meat regulations requires precise control of fat content. Fat analysis through food X-Ray inspection enables processors to measure fat levels in real time, directly on the production line. Unlike traditional lab methods, X-Ray inspection systems provide 100% inline inspection, ensuring every cut, portion, or batch meets regulatory limits. By leveraging advanced X-Ray inspection machines and X-Ray inspection equipment, meat producers can quickly detect deviations, adjust processing parameters, and maintain compliance without slowing down production.

Enhancing Product Consistency and Customer Satisfaction

Consistent fat content directly affects taste, texture, and nutritional labeling, which are critical for consumer satisfaction. X-Ray inspection systems with integrated fat analysis deliver accurate, high-speed measurement for all products. Real-time feedback from X-Ray inspection machines allows processors to standardize portions, maintain marbling uniformity, and minimize batch-to-batch variation. With food X-Ray inspection equipment, meat producers can confidently guarantee consistent quality, enhancing brand reputation and customer loyalty.

Case Examples of Meeting USDA, EU, And Other Market Standards

Meat processors exporting to the United States, Europe, and other global markets must comply with strict fat content requirements. Leading companies have adopted X-Ray inspection systems to perform comprehensive fat analysis inline. These systems ensure compliance with USDA, EU, and other market standards by providing precise, traceable data for every product. Advanced X-Ray inspection equipment enables documentation for audits, reduces risk of non-compliance, and facilitates smooth export operations. By integrating food X-Ray inspection machines into production, processors meet regulatory demands while maximizing efficiency and maintaining product quality.

Business Benefits for Meat Producers

Reduced Product Waste and Raw Material Cost Optimization

Implementing fat analysis via food X-Ray inspection allows meat producers to minimize trimming losses and maximize yield. X-Ray inspection systems can precisely measure fat distribution in every cut, ensuring that only the necessary fat is removed while retaining optimal lean meat content. By reducing over-trimming, companies optimize raw material usage, lower production costs, and reduce overall product waste. Using advanced X-Ray inspection machines and X-Ray inspection equipment, processors achieve more accurate portioning and consistent product quality, resulting in significant cost savings over time. Additionally, accurate fat measurement helps avoid product recalls or downgrades due to inconsistent fat content, further protecting profit margins.

Increased Production Efficiency with Inline Monitoring

Real-time X-Ray inspection enables continuous inline monitoring of fat content and product composition. Unlike traditional lab testing, X-Ray inspection systems provide instant feedback, allowing on-the-fly adjustments to trimming, portioning, and processing without stopping the production line. Food X-Ray inspection machines scan every item quickly and non-destructively, ensuring efficient grading, sorting, and portion control. This high-speed, automated monitoring not only improves throughput and reduces downtime but also minimizes human error. By integrating X-Ray inspection equipment into production workflows, meat processors can maintain uniform product standards, accelerate production cycles, and increase overall operational efficiency.

Strengthened Brand Reputation for Quality and Safety

Consistent quality and verified fat content enhance consumer trust and reinforce brand credibility. X-Ray inspection equipment with integrated fat analysis ensures that every product meets regulatory and internal quality standards, including national and international requirements. By documenting precise X-Ray inspection results, producers can provide verifiable data for audits, certifications, and customer assurance. Reliable food X-Ray inspection systems not only safeguard product safety but also support marketing claims about quality, health, and consistency. Companies using these advanced technologies demonstrate a commitment to transparency, traceability, and innovation, strengthening their reputation in competitive markets and fostering long-term customer loyalty.

The Future of Fat Analysis in Meat Processing

AI Integration for Enhanced Accuracy and Predictive Quality Control

The future of fat analysis in meat processing lies in the integration of AI with food X-Ray inspection technology. Advanced X-Ray inspection systems equipped with machine learning algorithms can not only measure fat content more accurately but also predict trends in product composition. By analyzing historical and real-time data from X-Ray inspection machines, producers can anticipate variations in fat distribution and make proactive adjustments. This predictive capability reduces waste, ensures consistent quality, and strengthens overall production control. AI-powered X-Ray inspection equipment enhances the reliability of measurements, enabling meat processors to maintain high standards while minimizing manual intervention.

Combining Fat Analysis with Foreign Object Detection in One System

Next-generation X-Ray inspection systems are increasingly capable of performing multiple quality checks in a single pass. By combining fat analysis with foreign object detection, such as metal, bone, or glass, food X-Ray inspection machines provide comprehensive safety and quality monitoring. This dual-function capability eliminates the need for separate inspection stages, streamlines production, and reduces operational costs. Integrated X-Ray inspection equipment ensures that each product meets both fat content specifications and contamination-free requirements, delivering consistent quality and safety to consumers.

Data Analytics for Production Optimization and Traceability

Modern X-Ray inspection systems generate large amounts of valuable data, enabling meat processors to optimize production processes and maintain traceability. Using sophisticated analytics tools, operators can track fat content trends, monitor deviations, and adjust line parameters in real time. X-Ray inspection machines equipped with data logging capabilities allow for detailed reporting and regulatory compliance verification. With food X-Ray inspection technology, producers gain insights into yield, waste, and efficiency metrics, supporting smarter decision-making and enhancing transparency across the supply chain. This data-driven approach ensures better product consistency, higher operational efficiency, and improved customer trust.

Conclusion

Summary of the Value of Fat Analysis X-Ray Inspection Systems

Fat Analysis X-Ray inspection systems offer meat producers a powerful solution for achieving consistent product quality, enhanced safety, and operational efficiency. By leveraging advanced X-Ray inspection machines and food X-Ray inspection equipment, processors can perform accurate, inline fat analysis for every cut of meat. These systems provide real-time insights into fat content, improve yield, minimize waste, and ensure compliance with national and international quality standards. Integrating X-Ray inspection into production not only enhances product consistency but also strengthens brand reputation by delivering safe and high-quality meat to the market.

Final Call-to-Action for Meat Producers to Adopt Advanced Quality Control Technologies

As consumer expectations and regulatory requirements continue to rise, adopting advanced X-Ray inspection systems with built-in fat analysis capabilities is no longer optional—it’s essential. Meat producers who implement food X-Ray inspection machines gain a competitive edge through precise quality control, reduced waste, and improved operational efficiency. By investing in modern X-Ray inspection equipment, processors can ensure every product meets exact fat specifications, maximize profitability, and maintain a trusted reputation in the marketplace. Now is the time to embrace innovative X-Ray inspection solutions and future-proof your meat processing operations.

FAQ

Q: What is fat analysis in meat processing?

A: Fat analysis measures the fat-to-lean ratio in meat products. Using advanced X-Ray inspection equipment, processors can accurately detect and control fat content in real time, ensuring consistent quality and compliance.

Q: How do Fat Analysis X-Ray Inspection Systems work?

A: These systems use X-Ray inspection machines to scan meat products. By detecting differences in density and absorption between fat and lean tissue, they provide precise fat analysis without damaging the product.

Q: Why is X-Ray inspection better than manual fat measurement?

A: Food X-Ray inspection eliminates human error, provides 100% inline scanning, and delivers faster, more reliable results compared to visual checks or random sampling.