Introduction

Overview of Food Safety Challenges in Large-Scale Bulk Food Processing

In today’s global food industry, bulk product processing—such as nuts, grains, seeds, and dried fruits—presents unique food safety challenges. Contaminants like metal fragments, stones, glass shards, or dense plastics can easily enter production lines during harvesting, handling, or transportation. At large volumes, even a small contamination incident can lead to massive recalls, financial losses, and long-term damage to brand reputation. This is why ensuring reliable contaminant detection has become a top priority in large-scale bulk food operations.

Why Traditional Inspection Methods (Manual Sorting, Metal Detectors) Are No Longer Sufficient

For many years, food producers relied on manual sorting or metal detectors to identify foreign objects in bulk products. However, manual sorting is slow, inconsistent, and labor-intensive, making it unsuitable for high-volume production lines. Metal detectors, while effective for ferrous and non-ferrous metals, cannot identify other hazardous contaminants such as glass, stones, or bones. As a result, traditional methods alone are no longer capable of meeting the strict safety and compliance requirements of modern bulk food production.

Introduction of X-Ray Inspection Equipment as a Modern Solution for Bulk Production Lines

To overcome these limitations, many manufacturers now rely on X-Ray inspection equipment. Unlike conventional systems, a food X-Ray inspection system uses density-based technology to identify both metallic and non-metallic contaminants in unpackaged bulk products. Whether through a conveyor-based X-Ray inspection machine or specialized bulk flow systems, this technology provides unmatched detection accuracy, high-speed operation, and traceable image records. By integrating X-Ray inspection equipment into bulk production lines, food producers can ensure product safety, maintain regulatory compliance, and strengthen consumer trust.

The Growing Need for Bulk Product Inspection

Common Risks in Unpackaged Bulk Products (Nuts, Seeds, Grains, Dried Fruits, Etc.)

Unpackaged bulk products such as nuts, seeds, grains, and dried fruits are especially vulnerable to contamination throughout the entire supply chain. During harvesting, foreign objects like small stones or soil clumps can mix in with the raw materials. In transportation and storage, products may encounter fragments of glass, broken metal parts from machinery, or even dense plastics from packaging residues. These contaminants often share a similar size or color with the food itself, making visual inspection extremely difficult.

Unlike packaged goods, bulk products flow freely and are often handled in large quantities, which adds another layer of complexity. A single undetected contaminant can easily spread through tons of material, magnifying the risk. This is why food X-Ray inspection systems have become a critical solution—they use density-based detection to identify metallic and non-metallic hazards with precision. By applying X-Ray inspection equipment at this stage, manufacturers can ensure that only clean, safe raw materials move forward in the production process.

High-Volume Production and Export Requirements Driving Demand for Bulk Product X-Ray Systems

With the rapid growth of global food trade, bulk food processors face increasing regulatory pressure. International markets demand strict safety certifications, such as HACCP, BRC, and FDA approvals, which require reliable contaminant detection far beyond the capabilities of manual sorting or metal detectors. For high-volume operations processing several tons of material per hour, the challenge is twofold: maintaining speed while ensuring safety.

Manual inspection is not only labor-intensive but also inconsistent, especially when dealing with thousands of small items like seeds or grains. Traditional metal detectors are limited to metallic contaminants, leaving processors vulnerable to other threats like glass, stone, or bone. In contrast, X-Ray inspection machines offer comprehensive detection without compromising throughput. A modern X-Ray inspection system can scan large quantities of unpackaged bulk products in real-time, automatically identifying and rejecting contaminated batches.

For exporters, this capability is crucial. A shipment rejected due to contamination not only causes financial loss but also damages long-term trade relationships. By investing in food X-Ray inspection equipment, manufacturers can meet international compliance requirements, enhance supply chain reliability, and protect their access to global markets.

The Impact of Contamination on Consumer Safety and Brand Reputation

The consequences of contamination extend far beyond immediate food safety concerns. Sharp foreign objects like glass, metal, or stones pose serious health risks, leading to injuries, hospitalizations, or even lawsuits. At the same time, the financial and reputational damage from a product recall can be devastating. Studies have shown that consumer trust is difficult to rebuild once a safety incident occurs, and in competitive food markets, a single contamination event can cause customers to permanently switch to another brand.

By implementing X-Ray inspection equipment at critical control points, companies can drastically reduce these risks. Early detection ensures that contaminated batches are intercepted before reaching consumers, preventing accidents and recalls. Furthermore, the advanced data recording features of many X-Ray inspection systems provide traceability, allowing manufacturers to quickly identify the source of contamination and take corrective actions.

In today’s digital age, where negative news spreads rapidly through social media, safeguarding brand reputation is just as important as ensuring consumer health. With reliable food X-Ray inspection machines, manufacturers not only meet compliance requirements but also demonstrate transparency, responsibility, and commitment to quality—values that resonate strongly with modern consumers.

How X-Ray Inspection Equipment Works in Bulk Processing

Explanation of Density-Based Detection Used in X-Ray Inspection Machines

At the core of X-Ray inspection equipment lies the principle of density-based detection. Unlike metal detectors that only identify conductive materials, an X-Ray inspection machine uses high-energy X-rays to scan bulk food products and generate contrast images. These images highlight differences in density between the food material and any foreign object present.

For example, contaminants such as glass, stone, or metal appear as denser regions compared to softer food products like nuts, grains, or dried fruits. This enables food X-Ray inspection to detect hazards that are invisible to the naked eye and undetectable by traditional technologies. By leveraging density-based detection, an X-Ray inspection system ensures a higher level of precision, providing manufacturers with an advanced tool to safeguard bulk production lines.

Application of X-Ray Inspection Systems on Conveyor Belts for Unpackaged Products

In large-scale bulk processing, products such as seeds, rice, or dried fruits are transported in free-flowing streams. This makes conveyor belt integration crucial for X-Ray inspection systems. As unpackaged bulk products move along the belt, the X-Ray inspection machine continuously scans them in real time.

The technology is designed for speed and consistency—capable of handling tons of material per hour without interrupting the flow of production. Contaminants are automatically identified and flagged for removal, ensuring that only safe food continues down the line. For producers, this conveyor-based application of X-Ray inspection equipment means they can maintain efficiency while meeting strict safety standards, all without adding unnecessary manual labor.

This seamless integration into processing lines makes food X-Ray inspection highly suitable for bulk operations where uninterrupted throughput and accuracy are both critical.

Types of Foreign Objects Detected: Metals, Glass, Stones, Bones, And Dense Plastics

One of the greatest advantages of X-Ray inspection machines in bulk processing is their versatility in detecting a wide variety of contaminants. While metal detectors are limited to ferrous and non-ferrous metals, X-Ray inspection systems can identify:

Metals (both ferrous and non-ferrous)

Glass fragments

Stones and mineral particles

Bones in dried or processed foods

Dense plastics and rubber that may enter during processing or packaging

This broad detection capability makes food X-Ray inspection the preferred choice for manufacturers who need comprehensive protection across their entire product range. By identifying multiple types of foreign objects at once, an X-Ray inspection machine not only ensures food safety but also reduces the risk of costly recalls and reputational damage.

Key Benefits of Food X-Ray Inspection for Large-Scale Processing

High Accuracy and Detection Sensitivity

One of the greatest advantages of food X-Ray inspection is its exceptional accuracy. An X-Ray inspection system can detect contaminants as small as a fraction of a millimeter, including glass shards, metal fragments, stones, bones, and dense plastics. Unlike traditional inspection methods, an X-Ray inspection machine is not limited to metallic materials—it can identify a wide range of hazardous objects. For large-scale bulk processing, this level of sensitivity ensures that even tiny contaminants are identified, protecting both consumer safety and brand reputation.

Non-destructive Inspection That Preserves Food Quality

Another major benefit of X-Ray inspection equipment is its non-destructive nature. The inspection process does not alter, damage, or affect the taste, texture, or quality of the product. Unlike manual sorting or invasive testing methods, food X-Ray inspection maintains product integrity while delivering highly accurate results. This is especially important in high-value items such as nuts, dried fruits, and seeds, where any damage to the product could reduce profitability.

Ability to Handle 24/7 Operations with Consistent Reliability

Modern X-Ray inspection machines are designed for continuous, high-volume production environments. In large-scale bulk food processing, downtime can be extremely costly. An X-Ray inspection system offers robust reliability, capable of operating 24/7 while maintaining consistent detection performance. This makes X-Ray inspection equipment an ideal solution for manufacturers seeking efficiency without compromising safety. The system’s durability and minimal maintenance requirements further support nonstop production, reducing bottlenecks and maximizing ROI.

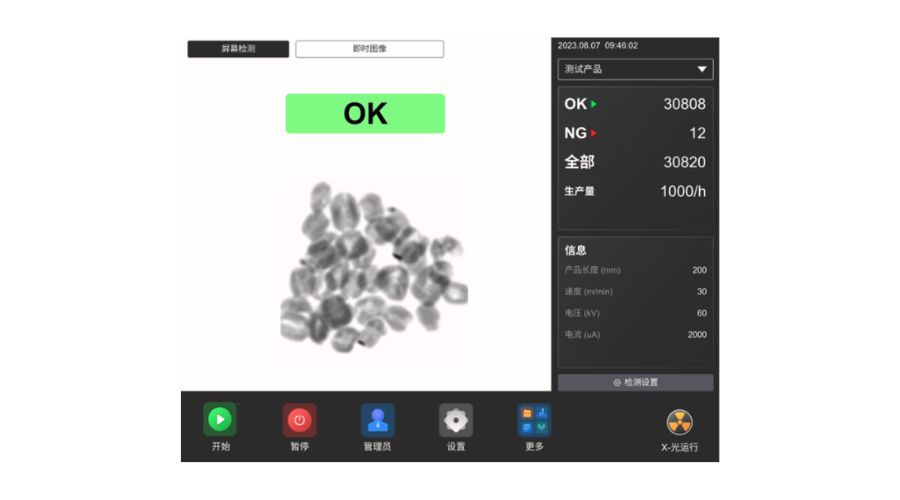

Data Recording and Traceability for Food Safety Audits

Food safety regulations increasingly require full traceability, and food X-Ray inspection systems play a crucial role in compliance. Advanced X-Ray inspection equipment provides real-time image recording and data storage, allowing manufacturers to document inspection results for audits and regulatory reviews. These records serve as proof of compliance with international food safety standards such as HACCP, BRC, and ISO. By incorporating X-Ray inspection machines into their production lines, manufacturers not only enhance quality control but also strengthen their ability to pass inspections and maintain export eligibility.

Comparing X-Ray Inspection Systems with Traditional Methods

X-Ray Inspection Equipment Vs. Metal Detectors: Broader Detection Capabilities

While metal detectors have long been used in food processing, their biggest limitation is that they can only detect metallic contaminants. In contrast, X-Ray inspection equipment provides far broader detection capabilities. An X-Ray inspection system can identify not only metals but also glass, stones, bones, ceramics, and dense plastics—hazards that metal detectors often miss. For bulk food processors, this expanded range of contaminant detection makes an X-Ray inspection machine a much more reliable and versatile solution compared to metal detectors.

Advantages over Manual Inspection: Efficiency, Consistency, And Speed

Manual inspection methods, such as visual sorting, are both labor-intensive and error-prone. Human operators may overlook small or hidden contaminants, especially in high-volume environments. By contrast, food X-Ray inspection systems work with unmatched speed and consistency, analyzing thousands of products per minute without fatigue or variation. An X-Ray inspection machine ensures reliable results in bulk production lines, reducing labor costs while boosting throughput. Compared with manual sorting, X-Ray inspection equipment delivers efficiency and precision that simply cannot be achieved by human inspection.

Why Food X-Ray Inspection Is the Preferred Choice for Modern Facilities

Modern food facilities face increasing regulatory demands, strict export standards, and heightened consumer expectations. This is why food X-Ray inspection has become the preferred choice for large-scale operations. An X-Ray inspection system not only enhances contaminant detection but also supports quality control by measuring product mass, counting items, and checking packaging integrity. Furthermore, X-Ray inspection machines are designed to integrate seamlessly into automated production lines, supporting 24/7 operations with minimal downtime. For processors aiming to balance safety, efficiency, and compliance, investing in X-Ray inspection equipment is no longer optional—it is essential for long-term success and brand protection.

Practical Considerations for Manufacturers

Best Installation Points for X-Ray Inspection Machines in Bulk Processing Lines

For bulk food processors, determining where to place an X-Ray inspection machine is critical to maximizing efficiency and safety. In most cases, X-Ray inspection equipment is installed at key control points, such as immediately after raw material cleaning, before packaging, or just prior to final dispatch. Positioning an X-Ray inspection system early in the production line allows contaminants like stones, glass, or metal fragments to be removed before they mix further into the product stream. For high-volume bulk products such as grains, nuts, and dried fruits, food X-Ray inspection ensures that contamination risks are addressed before packaging, reducing waste and ensuring compliance with export standards.

Training and Maintenance Requirements for Operators

Although modern X-Ray inspection equipment is designed for user-friendly operation, proper training is essential. Operators must understand how the X-Ray inspection system functions, how to interpret detection reports, and how to respond to contaminant alerts. Routine maintenance, such as calibration checks, image quality verification, and software updates, is also necessary to keep the X-Ray inspection machine performing at peak accuracy. Manufacturers who invest in comprehensive training programs ensure consistent performance and compliance, while minimizing downtime. With food X-Ray inspection, even small oversights in operation or maintenance can affect both safety outcomes and audit readiness, so ongoing operator education is key.

Cost-Benefit Analysis: Balancing Safety, Compliance, And ROI

Some manufacturers hesitate to invest in X-Ray inspection equipment due to upfront costs. However, when viewed through a cost-benefit lens, the return on investment is clear. A single contamination incident can lead to product recalls, legal penalties, and lasting brand damage—costs that far outweigh the expense of installing an X-Ray inspection system. Moreover, X-Ray inspection machines improve efficiency by reducing reliance on manual inspection and preventing costly rejections in export markets. Beyond safety, food X-Ray inspection also supports compliance with international standards, strengthens brand reputation, and enhances consumer trust. Ultimately, the financial and reputational benefits of adopting advanced X-Ray inspection equipment make it an indispensable tool for any manufacturer focused on long-term success.

Industry Applications and Case Studies

Real-World Use Cases: Nuts, Seeds, Grains, And Dried Fruit Industries

In industries handling bulk products like nuts, seeds, grains, and dried fruits, contamination risks are especially high. For example, stones may be mixed with harvested nuts, or fragments of glass can accidentally enter dried fruit batches during processing. Traditional inspection methods such as manual sorting or metal detectors often fail to detect non-metallic contaminants. By adopting food X-Ray inspection, processors can detect metals, glass, dense plastics, and even bones with high precision. Today, many large nut and dried fruit processors rely on X-Ray inspection machines to maintain consistent safety standards, protect consumers, and ensure their products are export-ready.

Examples of Companies Meeting Global Compliance Through X-Ray Inspection Systems

Compliance with global standards such as HACCP, BRC, ISO, and FDA regulations requires advanced inspection solutions. Many international companies have successfully integrated X-Ray inspection systems into their bulk food processing lines to meet these requirements. For example, grain exporters in Europe and nut processors in the Middle East use X-Ray inspection equipment to demonstrate adherence to strict safety standards demanded by importing countries. By implementing food X-Ray inspection, these businesses not only reduce the risk of recalls but also strengthen their credibility with global buyers. The use of X-Ray inspection machines has become a competitive advantage for companies that prioritize safety and compliance.

How Bulk Product X-Ray Inspection Supports Large-Scale Exports

Global food trade continues to expand, and with it, regulatory scrutiny has intensified. Exporters handling bulk shipments cannot afford contamination risks that could lead to rejected shipments or reputational harm. This is where X-Ray inspection equipment plays a crucial role. By installing X-Ray inspection machines at key points in bulk production lines, exporters can ensure that every shipment meets international safety expectations. Beyond compliance, food X-Ray inspection systems help maintain efficiency in high-volume operations, supporting 24/7 production while guaranteeing consistent results. For large-scale exporters of seeds, grains, nuts, and dried fruits, adopting X-Ray inspection equipment is no longer optional—it is a necessity to succeed in today’s competitive global marketplace.

Conclusion

Reinforcing the Role of X-Ray Inspection Equipment in Ensuring Bulk Food Safety

In large-scale bulk food processing, contamination risks are inevitable. From stones in grains to glass fragments in dried fruits, even small hazards can cause significant safety issues. X-Ray inspection equipment has proven to be one of the most reliable solutions for identifying such risks. By detecting both metallic and non-metallic contaminants, X-Ray inspection machines offer a level of precision and reliability far beyond traditional methods. This makes food X-Ray inspection systems an essential safeguard for protecting consumer health and ensuring product integrity.

Encouraging Manufacturers to Adopt Food X-Ray Inspection as a Long-Term Investment

For manufacturers, adopting an X-Ray inspection system is not just about compliance—it is about securing long-term success. Investing in X-Ray inspection equipment reduces the risk of recalls, strengthens brand reputation, and builds consumer trust. Moreover, modern X-Ray inspection machines are designed for durability and high throughput, making them a cost-effective choice in bulk processing environments. The long-term benefits—operational efficiency, regulatory compliance, and customer confidence—far outweigh the initial investment.

Final Call-to-Action: Protecting Consumers and Brands Through Safe, Efficient, And Reliable Inspection

In today’s competitive global food industry, safety and reliability are non-negotiable. By implementing food X-Ray inspection across bulk production lines, manufacturers can protect their consumers, safeguard their brands, and stay ahead of international regulations. Whether it is nuts, seeds, grains, or dried fruits, the role of X-Ray inspection equipment is clear: to provide safe, efficient, and dependable contaminant detection at every stage of processing. Now is the time for producers to adopt advanced X-Ray inspection systems—because protecting consumers means protecting the future of your brand.

FAQ

Q: Why are traditional inspection methods like manual sorting and metal detectors insufficient for bulk food processing?

A: Manual sorting is slow and inconsistent, while metal detectors only identify metals. They cannot detect hazards like glass, stones, or dense plastics, making them unsuitable for today’s high-volume, safety-focused food industry.

Q: What are the benefits of X-Ray inspection for large-scale bulk processing?

A: Benefits include high detection accuracy, non-destructive inspection, 24/7 reliability, traceability with image records, reduced recalls, and compliance with global food safety standards such as HACCP, BRC, and FDA.

Q: What is the ROI of investing in X-Ray inspection equipment?

A: Though upfront costs are higher, it prevents costly recalls, protects brand reputation, reduces manual labor, and ensures compliance—providing long-term financial and reputational benefits.