The Rise of Lightweight Snack Packaging

Overview of Lightweight Snack Bags as Part of Sustainable and Cost-Effective Packaging Trends

In the food industry, lightweight snack bags have become an essential element of sustainable packaging and cost-effective packaging solutions. These thin, flexible bags reduce material usage, lower transportation costs, and contribute to a smaller environmental footprint. Manufacturers aiming to maintain food safety standards are increasingly relying on X-Ray inspection systems and X-Ray inspection equipment to ensure that lightweight packaging does not compromise product integrity.

By integrating X-Ray inspection machines, producers can non-destructively scan lightweight snack bags for foreign objects such as metal, glass, or plastic fragments. This combination of eco-friendly packaging and advanced food X-Ray inspection ensures that sustainability and safety go hand in hand. Lightweight packaging also aligns with global trends toward reducing plastic waste and promoting green manufacturing practices, while X-Ray inspection technology safeguards the quality control process.

Market Demand for Portable, Convenient, and Eco-Friendly Snack Packaging

Consumer preferences are driving demand for portable, convenient, and eco-friendly snack packaging. Busy lifestyles and on-the-go snacking habits have created a need for snack bags that are resealable, easy to carry, and portion-controlled. At the same time, eco-conscious consumers increasingly expect products that reflect environmentally responsible packaging practices.

To meet these expectations, manufacturers are adopting lightweight snack bags while implementing X-Ray inspection machines and X-Ray inspection equipment on production lines. These systems provide precise food X-Ray inspection, ensuring that contaminants are detected without damaging delicate packaging. The integration of X-Ray inspection systems not only maintains product quality but also enhances brand trust in the growing market for sustainable and safe snack packaging.

Risks and Hidden Contaminants in Lightweight Snack Bags

Contaminants That Are Hard to Detect Due to Thin Packaging

Lightweight snack bags offer benefits like portability and sustainability, but their thin and flexible design presents challenges for contaminant detection. Foreign objects such as metal fragments, glass shards, stones, plastic pieces, and food debris can inadvertently enter the packaging during production or recycling. These hidden contaminants pose serious food safety risks and can compromise product quality if undetected.

To effectively address these risks, many manufacturers rely on X-Ray inspection machines and X-Ray inspection systems. By using industrial X-Ray inspection equipment, it is possible to non-destructively scan each lightweight snack bag, even when contaminants are small or embedded in multilayer packaging. Advanced food X-Ray inspection ensures that every snack bag meets quality control standards without slowing down high-speed production lines.

How Lightweight and Flexible Materials Can Mask Foreign Objects

The very properties that make lightweight snack bags attractive—thinness, flexibility, and transparency—can also mask foreign objects, making them difficult to detect with traditional inspection methods. Wrinkles, folds, or overlapping layers can hide contaminants from standard visual checks.

Here, X-Ray inspection systems play a crucial role. Equipped with high-resolution imaging and adaptable detection settings, these X-Ray inspection machines can penetrate flexible packaging to identify hidden contaminants accurately. By integrating X-Ray inspection equipment into production lines, snack manufacturers can reduce the risk of undetected foreign objects, safeguard consumer safety, and maintain brand trust.

How X-Ray Technology Adapts to Lightweight Packaging

Sensitivity Adjustments – Configuring X-Ray Machines for Thin Materials

Inspecting lightweight snack bags requires precise calibration because thin packaging can make foreign objects harder to detect. Modern X-Ray inspection machines allow for sensitivity adjustments, enabling operators to fine-tune X-Ray inspection equipment to detect even the smallest metal, glass, or plastic fragments without damaging the bag. By optimizing sensitivity, manufacturers can ensure accurate food X-Ray inspection while maintaining production speed and quality control standards.

Multi-Layer Detection – Handling Laminated or Composite Snack Bags

Many lightweight snack bags are made from laminated or composite materials for barrier protection and durability. These multi-layer designs can mask hidden contaminants during traditional inspection methods. Advanced X-Ray inspection systems and industrial X-Ray inspection equipment are capable of multi-layer detection, effectively penetrating each layer to identify hidden foreign objects. This technology ensures that food safety is maintained even in complex packaging structures.

Real-Time Imaging – Ensuring High-Speed Production Lines Are Accurately Monitored

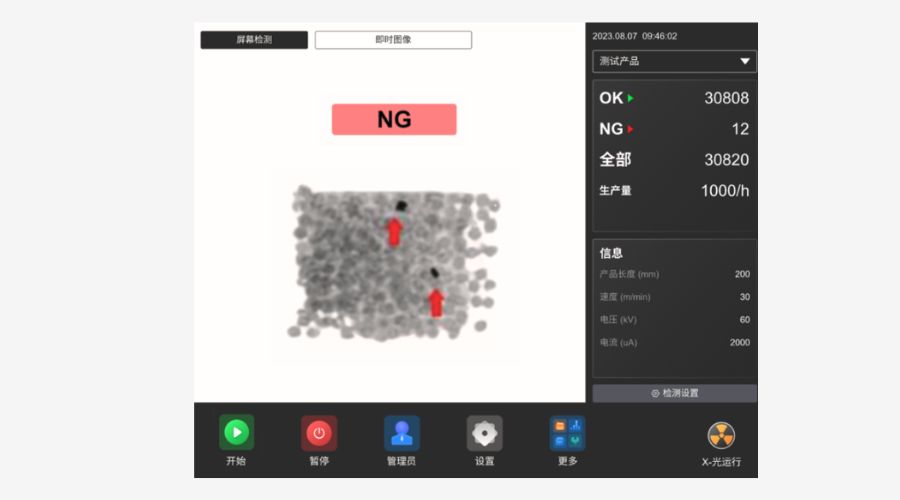

High-speed snack production lines demand real-time monitoring to prevent contaminated products from reaching consumers. X-Ray inspection machines equipped with real-time imaging allow manufacturers to continuously scan lightweight snack bags without slowing down production. Integration with automated X-Ray inspection systems ensures instant detection of contaminants, supporting rapid decision-making and minimizing waste. This capability is essential for maintaining food X-Ray inspection standards and protecting brand reputation.

Key Advantages of X-Ray Inspection in Snack Production

Detection of Contaminants Without Damaging the Bag

One of the primary benefits of X-Ray inspection is its ability to detect contaminants in lightweight snack bags without compromising packaging integrity. Using advanced X-Ray inspection machines and industrial X-Ray inspection equipment, manufacturers can non-destructively identify foreign objects such as metal fragments, glass shards, stones, and plastic pieces. This ensures that food safety and product quality are maintained while minimizing production waste.

Effective for High-Speed Production Lines While Maintaining Throughput

Modern X-Ray inspection systems are designed for high-speed production environments, making them ideal for snack manufacturers who need to maintain efficiency without sacrificing safety. With real-time imaging and rapid scanning capabilities, food X-Ray inspection can be performed on thousands of bags per hour, ensuring consistent quality control even on fast-moving conveyor lines.

Detects Both Metallic and Non-Metallic Foreign Objects

Unlike traditional metal detectors, X-Ray inspection machines and X-Ray inspection equipment can detect a wide range of foreign objects, including both metallic and non-metallic contaminants. This includes stones, glass, hard plastics, and other dense materials that may be invisible to standard detection methods. This capability significantly enhances food safety standards for lightweight snack bags.

Supports Compliance With Food Safety Regulations

Using X-Ray inspection systems ensures that snack manufacturers meet stringent food safety regulations. By providing consistent and reliable food X-Ray inspection, these machines help companies comply with both local and international standards, reduce the risk of recalls, and protect brand reputation. Integrating X-Ray inspection technology into production lines is now considered a best practice for quality assurance in the modern snack industry.

Overcoming Challenges in Lightweight Snack Bag Inspection

Dealing with Low-Density or Translucent Bags

Inspecting lightweight snack bags presents unique challenges, particularly when dealing with low-density or translucent packaging. Traditional detection methods may struggle to identify foreign objects hidden within thin or transparent materials. Modern X-Ray inspection machines and X-Ray inspection systems overcome this issue by adjusting sensitivity and imaging parameters, allowing food X-Ray inspection to detect contaminants accurately without compromising bag integrity. Using advanced X-Ray inspection equipment, even subtle density variations can be identified, ensuring reliable quality control.

Reducing False Positives Caused by Bag Wrinkles or Folds

Another common challenge in lightweight packaging is the occurrence of false positives due to wrinkles, folds, or overlapping layers. These irregularities can be mistakenly flagged as contaminants, resulting in unnecessary rejections and production waste. High-precision X-Ray inspection systems equipped with intelligent imaging algorithms can differentiate between actual foreign objects and harmless packaging variations. By implementing X-Ray inspection machines with adaptive software, manufacturers can reduce false positives while maintaining high inspection accuracy for food safety.

Maintaining Inspection Accuracy Despite High Line Speed

High-speed snack production lines demand that X-Ray inspection equipment operates efficiently without missing contaminants. Advanced X-Ray inspection machines with real-time imaging and rapid scanning capabilities allow manufacturers to maintain inspection accuracy even at maximum production speeds. Integrating these systems into automated food X-Ray inspection processes ensures that every lightweight snack bag is thoroughly checked, supporting regulatory compliance and protecting brand reputation.

Best Practices for Effective X-Ray Inspection of Snack Bags

Machine Calibration Specific to Thin Snack Packaging

For reliable X-Ray inspection of lightweight snack bags, proper machine calibration is essential. Thin or low-density packaging can make it difficult to distinguish foreign objects from harmless variations in material. By calibrating X-Ray inspection machines and X-Ray inspection equipment specifically for thin snack packaging, manufacturers ensure accurate food X-Ray inspection and reduce the risk of missed contaminants. Regular calibration also supports consistent quality control and minimizes unnecessary production waste.

Periodic Verification and Maintenance of X-Ray Systems

Maintaining the performance of X-Ray inspection systems is critical for long-term reliability. Periodic verification and preventive maintenance of X-Ray inspection machines and industrial X-Ray inspection equipment help prevent downtime and ensure that every lightweight snack bag is inspected with precision. Routine checks of detectors, imaging software, and conveyor alignment support consistent food safety standards and enhance overall inspection efficiency.

Using AI Algorithms to Distinguish Contaminants from Packaging Artifacts

Integrating AI algorithms with X-Ray inspection systems is a best practice that significantly improves detection accuracy. AI can analyze imaging data from X-Ray inspection machines to differentiate true foreign objects from harmless packaging artifacts such as wrinkles, folds, or multilayer overlaps. This advanced approach to food X-Ray inspection reduces false positives, increases production efficiency, and ensures that lightweight snack bags meet strict quality control and food safety standards.

Conclusion

Reinforce the Importance of X-Ray Inspection for Lightweight Snack Bags

In today’s fast-paced food industry, X-Ray inspection has become an essential component for ensuring the safety and quality of lightweight snack bags. By employing advanced X-Ray inspection machines and X-Ray inspection equipment, manufacturers can reliably detect foreign objects, including both metallic and non-metallic contaminants, without compromising packaging integrity. Implementing a comprehensive X-Ray inspection system allows snack producers to maintain food safety standards while meeting high production throughput.

Emphasize Technology’s Role in Ensuring Safety, Efficiency, and Regulatory Compliance

Technology plays a critical role in modern food X-Ray inspection processes. High-speed X-Ray inspection machines integrated with X-Ray inspection systems provide real-time imaging, AI-assisted detection, and automated rejection, ensuring that every lightweight snack bag leaving the production line is safe for consumers. Beyond safety, these systems enhance production efficiency, reduce waste, and support compliance with regulatory requirements. By adopting advanced X-Ray inspection equipment, manufacturers can achieve the perfect balance between quality control, operational efficiency, and sustainable packaging practices.

FAQ

Q1: Why is X-Ray inspection important for lightweight snack bags?

A1: Lightweight snack bags are thin and flexible, making contaminants like metal, glass, or plastic hard to detect. X-Ray inspection machines provide non-destructive, reliable detection to ensure food safety and quality control.

Q2: How do AI algorithms improve X-Ray inspection?

A2: AI analyzes imaging data to distinguish actual foreign objects from harmless packaging artifacts like folds, wrinkles, or multilayer overlaps, reducing false positives.

Q3: Does X-Ray inspection damage snack bags?

A3: No. Food X-Ray inspection is non-destructive, allowing manufacturers to detect contaminants while preserving packaging integrity.