Introduction

Metal contamination remains one of the most serious safety risks in modern food manufacturing. From raw material handling to final packaging, even microscopic metal fragments can lead to costly recalls, regulatory penalties, and damage to brand reputation. As production lines become faster and more automated, ensuring reliable metal detection has become a non-negotiable requirement for manufacturers committed to food safety, product integrity, and regulatory compliance.

While many processors focus heavily on detector technology itself, an often-overlooked factor is the conveyor system that carries the product through the inspection point. In reality, metal detection performance is the result of a complete system working together—detector, conveyor, product presentation, and operating environment.

The Critical Role of Metal Detection in Food Safety and Quality Assurance

Metal detectors play a vital role in preventing foreign body contamination across the entire food supply chain. In practical terms, what do metal detectors detect? They are designed to identify ferrous, non-ferrous, and stainless-steel contaminants that may enter products during processing, cutting, grinding, or packaging.

To understand their importance, it helps to know how does a metal detector work in a food processing environment. In simple terms, how a metal detector works is by generating an electromagnetic field that reacts when metal passes through it, triggering a reject mechanism to remove contaminated products from the line. This process supports HACCP programs, GFSI standards, and retailer audit requirements.

For manufacturers, food industry metal detectors are not only about compliance—they are a core part of quality assurance strategies. Whether used as a metal detector in food industry applications such as meat, bakery, dairy, or snacks, or as a metal detector for food production line inspection at critical control points, reliable detection helps protect consumers while minimizing costly downtime and false rejects.

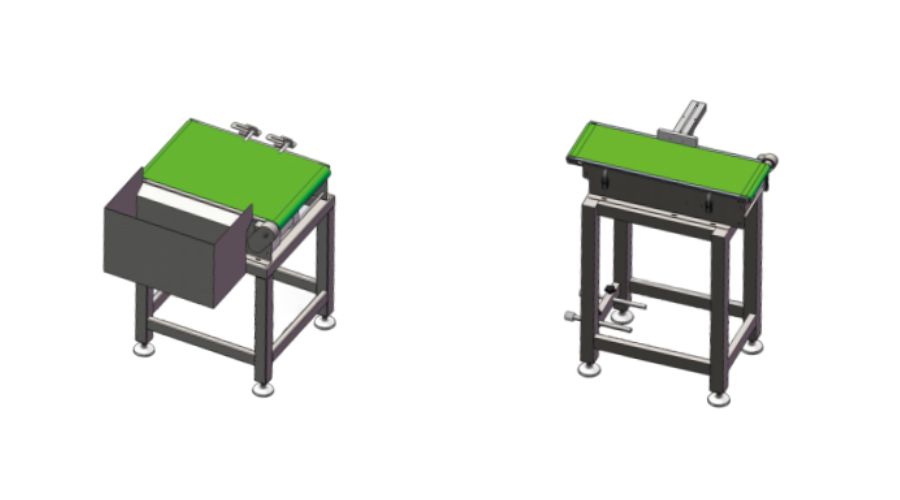

Why Conveyor Systems Are Not Just Transport Tools but Part of the Detection System

Although often viewed as simple material-handling equipment, conveyors play a direct role in detection accuracy. In fact, the conveyor structure, materials, speed, and stability all influence how the metal detector works in real-world conditions.

The conveyor effectively defines the inspection zone. Belt material, frame construction, rollers, fasteners, and even motor placement can introduce electrical noise or signal interference. Poorly designed conveyors may reduce sensitivity, increase false positives, or mask real contamination—regardless of how advanced the detector itself may be.

This is why modern food industry metal detectors are typically engineered as integrated systems rather than standalone devices. When asking what can a metal detector detect, the honest answer depends not only on the detector head but also on how the conveyor presents the product to the sensing aperture. Proper conveyor design ensures stable product flow, consistent orientation, and minimal background interference, all of which are essential for accurate contamination detection.

Overview of How Conveyor Design Directly Influences Metal Detector Accuracy, Sensitivity, And Reliability

Conveyor design affects three core aspects of detection performance: accuracy, sensitivity, and long-term reliability. Factors such as belt width, product height, vibration, speed consistency, and mechanical stability all impact how the metal detector works during continuous production.

For example, excessive vibration or inconsistent product spacing can weaken signal clarity, reducing the system’s ability to detect small contaminants. Similarly, metal components placed too close to the detection head can compromise sensitivity and increase false rejects. These issues directly affect food safety, operational efficiency, and overall inspection credibility.

In high-throughput environments, especially those using a metal detector for food production line inspection, optimizing conveyor design is essential for maintaining reliable foreign body detection and reducing unnecessary product waste. A well-matched conveyor and detector system ensures stable performance over time, supporting compliance, quality control, and brand protection in demanding food production environments.

The Relationship Between Conveyors and Metal Detectors

In modern food manufacturing, metal detectors and conveyors function as a single inspection system rather than independent components. The conveyor determines how products enter, pass through, and exit the inspection area, directly influencing detection reliability. Understanding this relationship is essential for manufacturers aiming to improve food safety, reduce false rejects, and maintain consistent inspection performance across high-speed production lines.

How Metal Detectors Work in a Conveyor-Based Food Production Line

To fully understand metal detection performance, it is important to examine how does a metal detector work when integrated into a conveyor-based production line. In this setup, products are transported at a controlled speed through the detector’s sensing aperture, where an electromagnetic field is continuously monitored.

At its core, how a metal detector works is by detecting disturbances in this field when metallic contaminants pass through. This answers a common question in the industry: what do metal detectors detect? They identify ferrous, non-ferrous, and stainless-steel contaminants that may originate from processing equipment, raw materials, or packaging components.

In conveyor applications, timing is critical. The detector must precisely synchronize with belt speed and product position to activate the reject mechanism at the correct moment. This is why a metal detector for food production line inspection must be carefully matched to conveyor specifications. Inconsistent speed, unstable product flow, or vibration can compromise how the metal detector works, reducing detection accuracy and increasing product loss.

The Concept of the “Detection Zone” and Its Dependence on Conveyor Structure

The “detection zone” refers to the three-dimensional space within the detector aperture where metal contamination can be reliably identified. While often assumed to be solely defined by the detector head, this zone is heavily influenced by conveyor design and construction.

Conveyor belt materials, frame components, rollers, and fasteners can all affect signal stability. Metal parts placed too close to the aperture may interfere with detection, narrowing the effective detection zone and limiting what can a metal detector detect in real-world production conditions. Even non-metallic materials with inconsistent density can impact signal clarity.

For food industry metal detectors, maintaining a stable and interference-free detection zone is critical. Proper conveyor design ensures consistent product positioning, minimal vibration, and controlled spacing, all of which support reliable foreign body detection. In this sense, the conveyor does not merely transport products—it actively defines the boundaries and effectiveness of the inspection process.

Common Misconceptions: Why Detector Performance Is Not Only About the Detector Itself

One of the most common misconceptions in the metal detector in food industry is the belief that upgrading the detector alone will solve performance issues. While advanced electronics and software play an important role, they cannot compensate for poor conveyor design or unstable mechanical conditions.

Manufacturers often ask what can a metal detector detect or assume that sensitivity limitations are purely a hardware issue. In reality, factors such as belt vibration, inconsistent product orientation, electrical noise, and improper grounding can significantly reduce inspection accuracy—even in high-end systems.

This is why leading food industry metal detectors are designed as integrated solutions rather than standalone units. The conveyor, detector, and reject system must work together to achieve consistent detection performance and support food safety standards. Viewing the inspection process as a complete system allows food producers to reduce false rejects, improve contamination control, and maintain long-term reliability on demanding production lines.

Conveyor Materials and Their Impact on Detection Sensitivity

Detection sensitivity is one of the most critical performance indicators for metal detection in food production. While many manufacturers focus on detector electronics, the materials used in conveyor construction have a direct and measurable effect on how a metal detector works in real-world environments. From belt composition to frame materials and mechanical components, every material choice influences signal stability, noise levels, and long-term inspection reliability—key factors for maintaining high food safety standards.

Belt Materials (PVC, PU, Rubber, Modular Plastic) and Signal Interference

Conveyor belt material plays a crucial role in determining how does a metal detector work as products pass through the sensing aperture. Different materials exhibit varying electrical and physical properties, which can affect signal consistency and background noise.

PVC and PU belts are commonly used in food processing due to their smooth surfaces and hygienic properties. PU belts, in particular, offer stable dielectric characteristics, making them well suited for high-sensitivity inspection. Rubber belts, while durable, may introduce greater signal variability due to thickness inconsistency or embedded reinforcement materials. Modular plastic belts, although popular for washdown environments, can create fluctuating signals if not properly designed for use with food industry metal detectors.

Because what do metal detectors detect is determined by changes in electromagnetic signals, unstable belt materials can mask small contaminants or trigger false rejects. Selecting the right belt material is therefore essential for any metal detector for food production line that requires reliable foreign body detection and consistent inspection accuracy.

Frame Materials: Stainless Steel VS. Painted Steel VS. Aluminum

The conveyor frame forms the structural backbone of the inspection system, and its material selection directly affects how the metal detector works under continuous operation. In food environments, stainless steel is the most widely used option due to its corrosion resistance, hygienic design, and compatibility with washdown conditions.

However, stainless steel must be carefully positioned and properly grounded near detection zones. Painted steel frames may introduce inconsistencies over time as coatings wear, potentially increasing electrical noise. Aluminum frames, while lightweight and non-magnetic, can still influence detection signals if placed too close to the aperture.

For metal detector in food industry applications, improper frame material selection can limit what can a metal detector detect in practice. Even highly sensitive detectors may underperform if surrounding structures introduce electromagnetic interference. This is why integrated conveyor and detector design is critical for maintaining detection sensitivity and minimizing false alarms.

The Risks of Metal Components Within or Near the Detection Area

One of the most common causes of reduced detection performance is the presence of metal components within or too close to the detection zone. Rollers, fasteners, motor shafts, bearings, and support brackets can all interfere with how a metal detector works if they are improperly positioned.

These components may create constant background signals that reduce sensitivity, making it more difficult to detect small contaminants. This directly impacts what do metal detectors detect, as signal masking can prevent the identification of fine metal fragments that pose serious food safety risks.

In a high-speed metal detector for food production line, even minor mechanical interference can result in increased false rejects or missed contamination events. Careful layout planning and the use of non-metal alternatives in critical areas are essential for reliable inspection performance.

Best Practices for Non-metal and Low-Interference Conveyor Design

To maximize detection sensitivity, best-in-class conveyor systems are designed with low-interference principles in mind. This includes using non-metal or metal-free zones around the detector aperture, stable belt materials, and vibration-resistant structures.

For food industry metal detectors, best practices include minimizing metallic components near the sensing head, ensuring proper grounding, and maintaining consistent belt speed and tension. These measures help stabilize signals and improve how the metal detector works under varying production conditions.

Ultimately, understanding what can a metal detector detect is not only about detector specifications—it is about system-level optimization. By applying thoughtful conveyor design, food manufacturers can enhance contamination detection, reduce product waste, and strengthen food safety and quality assurance across their production lines.

Conveyor Geometry and Layout Considerations

Conveyor geometry and layout play a decisive role in determining inspection accuracy in conveyor-based metal detection systems. Even when using advanced food industry metal detectors, poor geometric alignment between the conveyor, product, and detector aperture can significantly reduce detection sensitivity. Proper layout ensures consistent product presentation, stable signal conditions, and reliable contamination detection—key factors for maintaining high food safety standards.

Belt Width, Product Height, And Aperture Size Matching

One of the most critical design considerations is the relationship between belt width, product height, and detector aperture size. To understand how does a metal detector work effectively, it is important to recognize that detection sensitivity decreases as the aperture size increases. Larger apertures generate weaker detection fields, reducing the system’s ability to identify small contaminants.

This directly affects what do metal detectors detect in a production environment. Oversized apertures may fail to detect fine metal fragments, while undersized apertures can cause unnecessary product restrictions. For a metal detector for food production line, matching the aperture size as closely as possible to the product dimensions allows the detector to operate at optimal sensitivity, improving inspection accuracy and reducing false rejects.

Effects of Uneven Product Positioning and Product “tumbling”

Consistent product positioning is essential for stable detection performance. When products tumble, tilt, or shift unpredictably on the conveyor, signal patterns fluctuate, making it harder for the system to interpret detection signals accurately. This variability directly influences how the metal detector works during real-time inspection.

Uneven product presentation can also limit what can a metal detector detect, as contaminants may move to positions where detection sensitivity is lower. In high-speed environments, this can lead to missed contamination or increased false rejects—both of which negatively impact operational efficiency and food safety.

To support reliable detection in a metal detector in food industry application, conveyors should be designed to stabilize products using guides, sidewalls, or product spacing mechanisms that maintain consistent orientation through the detection zone.

Incline, Decline, And Curved Conveyor Sections near Metal Detectors

Inclined, declined, or curved conveyor sections can introduce mechanical and positional instability that affects how a metal detector works. Changes in elevation or direction often cause products to accelerate, decelerate, or shift, disrupting signal consistency and detection timing.

These layout features may also interfere with what do metal detectors detect by altering the distance between the product and the sensing coils. For food industry metal detectors, best practice is to avoid placing detection heads near conveyor transitions. When unavoidable, additional engineering measures—such as extended straight sections or controlled belt speed—are required to maintain reliable inspection performance.

Recommended Straight-Run Distances Before and After the Detector

Straight-run conveyor sections before and after the detector are essential for stabilizing product flow and ensuring accurate detection and rejection. These sections allow products to enter the detection zone in a controlled and repeatable manner, supporting how the metal detector works under consistent conditions.

Insufficient straight-run length can compromise what can a metal detector detect, as unstable product motion may distort signals or delay reject timing. For a metal detector for food production line, manufacturers typically recommend specific straight-run distances based on belt speed, product size, and reject mechanism type.

By adhering to these layout guidelines, food manufacturers can significantly improve detection sensitivity, reduce false rejects, and strengthen overall food safety and quality control performance.

Conveyor Speed and Product Spacing

How Belt Speed Influences Detection Time and Signal Stability

Belt speed determines how long a product remains within the detector’s sensing field, which directly affects detection time and signal stability. To understand how does a metal detector work in a conveyor-based system, it is important to recognize that sufficient exposure time is required for the detector to identify disturbances caused by metallic contaminants.

At higher belt speeds, the available detection window becomes shorter, making it more challenging for the system to reliably detect small or low-density metal fragments. This directly impacts what do metal detectors detect, as insufficient detection time may reduce sensitivity and increase the risk of missed contaminants. In addition, rapid belt movement can introduce mechanical vibration, further destabilizing signals and affecting how the metal detector works under real production conditions.

For a metal detector for food production line, matching belt speed to detector capability is essential to maintain inspection accuracy while supporting throughput requirements.

Product Spacing Consistency and Its Effect on False Rejects

Consistent product spacing plays a key role in ensuring reliable detection and rejection. When products are too close together or overlap, signal interference can occur, making it difficult for the system to distinguish individual items. This affects what can a metal detector detect, particularly in high-density product flows.

Inconsistent spacing can also cause false rejects, where clean products are mistakenly removed due to overlapping signals or incorrect timing of the reject mechanism. For a metal detector in food industry application, false rejects not only reduce line efficiency but also increase product waste and operational costs.

Maintaining uniform spacing through proper conveyor design and control systems helps stabilize detection signals, improves rejection accuracy, and supports overall food safety and quality assurance goals.

High-Speed Production Challenges and Optimization Strategies

High-speed production lines present unique challenges for metal detection, including reduced detection time, increased vibration, and tighter synchronization requirements. While modern food industry metal detectors are designed to operate at high throughput, system-level optimization is essential to maintain reliable inspection performance.

To ensure consistent detection at high speeds, manufacturers must consider conveyor stability, precise encoder feedback, and optimized reject timing. These measures help ensure how a metal detector works remains reliable even under demanding conditions. Additionally, segmenting products, using controlled acceleration zones, and implementing advanced signal processing can expand what do metal detectors detect without sacrificing line efficiency.

By addressing these challenges proactively, food producers can achieve a balance between productivity and food safety, ensuring that metal contamination risks are effectively managed across fast-moving production lines.

Vibration, Mechanical Stability, and Noise Interference

How Conveyor Vibration Can Create Detection Noise

Conveyor vibration introduces fluctuations that can interfere with the detector’s electromagnetic field, creating what is commonly referred to as detection noise. To understand how does a metal detector work under these conditions, it is important to recognize that metal detection relies on stable, repeatable signal patterns.

When vibration is present, the detector may interpret mechanical movement as a disturbance, affecting how the metal detector works and reducing its ability to accurately identify real contaminants. This can distort what do metal detectors detect, particularly when attempting to detect small metal fragments or low-density stainless steel.

In a metal detector for food production line, unmanaged vibration can lead to increased false rejects or missed contamination events, directly impacting production efficiency and food safety compliance.

Impact of Worn Rollers, Loose Frames, And Motor Placement

Worn rollers, loose conveyor frames, and improperly placed motors are common sources of both mechanical and electrical interference. Over time, these issues can intensify vibration and introduce inconsistent movement, making it harder for the system to interpret detection signals accurately.

Poor motor placement, especially near the detection head, can generate electromagnetic interference that affects what can a metal detector detect in practical applications. Similarly, loose or aging components can cause irregular belt motion, disrupting how a metal detector works during continuous operation.

For metal detector in food industry environments, these mechanical issues not only degrade detection accuracy but also increase maintenance requirements and unplanned downtime—both of which can compromise quality assurance and inspection reliability.

Strategies to Improve Mechanical Stability and Reduce Electrical Interference

Improving mechanical stability begins with robust conveyor design and proactive maintenance. Using precision-balanced rollers, rigid frame structures, and vibration-dampening mounts helps stabilize belt movement and protect how the metal detector works under demanding conditions.

To reduce electrical interference, motors and control cabinets should be positioned away from the detection zone, with proper grounding and shielded cabling. These strategies enhance signal clarity and expand what do metal detectors detect by minimizing background noise.

For food industry metal detectors, adopting a system-level approach that integrates mechanical design, electrical layout, and preventive maintenance is essential. These measures not only reduce false rejects and missed detections but also strengthen long-term food safety performance and operational reliability across the entire metal detector for food production line.

Integration of Metal Detectors with Conveyor Systems

Effective metal detection in food production depends not only on detection accuracy but also on precise system integration. Even the most advanced food industry metal detectors cannot deliver reliable performance without seamless coordination between the detector, conveyor, and reject system. Proper integration ensures contaminated products are accurately identified, rejected, and documented—supporting operational efficiency and food safety compliance.

Reject Mechanisms (Air Blast, Pusher, Drop Flap) and Conveyor Compatibility

Reject mechanisms are the final action point in the inspection process, removing contaminated products from the line once metal is detected. Common reject options include air blast systems, pushers, and drop flaps, each requiring specific conveyor configurations to function effectively.

To fully understand how does a metal detector work in a conveyor system, it is important to consider how detection signals trigger reject actions. If the reject mechanism is not properly matched to conveyor speed, product type, and spacing, detection accuracy may be compromised—even if what do metal detectors detect is correctly identified.

For a metal detector for food production line, reject compatibility is critical. Inadequate reject timing or insufficient separation can result in missed rejects or excessive product loss, undermining how the metal detector works in real production environments and reducing inspection credibility.

Synchronization Between Detector Signals and Conveyor Movement

Precise synchronization between detector signals and conveyor movement is essential for accurate rejection. This synchronization ensures that the correct product is removed at the exact moment contamination is detected.

When synchronization is poor, it can distort what can a metal detector detect in practice—not because the detector fails to sense metal, but because the reject system activates too early or too late. This issue is especially critical in high-speed metal detector in food industry applications where even minor timing errors can lead to false rejects or missed contamination events.

Using encoders, speed sensors, and integrated control logic helps align detection signals with conveyor motion, ensuring how a metal detector works remains reliable across varying line speeds and production conditions.

The Importance of Proper System Integration and Commissioning

System integration does not end with installation. Proper commissioning is essential to verify that all components—detector, conveyor, reject system, and controls—operate together as a unified inspection solution.

During commissioning, parameters such as belt speed, reject delay, product spacing, and detection sensitivity are tested and fine-tuned. This process confirms what do metal detectors detect under real production conditions and ensures consistent performance aligned with food safety and quality assurance requirements.

For food industry metal detectors, professional integration and commissioning reduce operational risks, minimize false rejects, and improve long-term reliability. A fully integrated metal detector for food production line not only enhances contamination control but also delivers measurable improvements in efficiency, compliance, and brand protection.

Common Conveyor Design Mistakes That Reduce Metal Detector Performance

Even the most advanced food industry metal detectors cannot perform optimally if the conveyor design is flawed. Several common mistakes in conveyor layout, materials, and electrical setup can significantly compromise detection sensitivity, increase false rejects, and threaten food safety. Recognizing and correcting these mistakes is essential for reliable operation in a metal detector for food production line.

Using Metal Fasteners or Rollers Too Close to the Detection Head

One of the most frequent errors is placing metal fasteners, bolts, or rollers near the detector aperture. Even small amounts of nearby metal can interfere with the electromagnetic field and reduce how the metal detector works. This interference may mask small contaminants, negatively impacting what can a metal detector detect.

In practice, improper placement of metallic components often leads to false alarms, unnecessary product rejection, or missed contamination. For metal detector in food industry applications, careful planning to keep all metallic objects outside the detection zone is critical to maintain accurate inspection performance.

Inadequate Straight Conveyor Sections

Conveyor straight-run length directly affects product stability and detection reliability. Insufficient straight sections before and after the detector can result in uneven product presentation, tumbling, or misalignment. This, in turn, affects how does a metal detector work, making it harder for the system to consistently identify foreign objects.

A metal detector for food production line needs straight conveyor sections that allow products to enter the sensing zone smoothly and consistently. Without adequate straight runs, food industry metal detectors may generate increased false rejects or fail to detect small contaminants, undermining food safety standards.

Mismatched Conveyor Speed and Detector Capability

Another common mistake is running the conveyor at a speed that exceeds the detector’s capacity to accurately sense metal. High belt speeds reduce the time products spend in the detection zone, which directly impacts what do metal detectors detect.

Even with high-sensitivity electronics, if the belt moves too fast for the system to respond, how a metal detector works becomes compromised. Synchronizing detector capability with conveyor speed is especially important in high-throughput metal detector in food industry operations to minimize missed contaminants and false rejects.

Poor Grounding and Electrical Layout

Electrical noise caused by poor grounding, incorrect wiring, or proximity to motors and other high-power equipment can degrade detector performance. This interference distorts signals, affecting how the metal detector works and reducing sensitivity to contaminants.

For food industry metal detectors, proper grounding, shielded cabling, and thoughtful electrical layout are essential to ensure reliable performance. Correct electrical design supports consistent operation, maximizes what can a metal detector detect, and ensures the system meets food safety and HACCP compliance requirements.

Conclusion

A well-designed conveyor system is as important as the metal detector itself for ensuring reliable contamination detection in food production. The combination of conveyor materials, geometry, speed, and integration with the detector determines overall performance. By understanding these factors, manufacturers can improve food safety, reduce false rejects, and maintain operational efficiency across high-speed production lines.

Summary of How Conveyor Design Directly Affects Metal Detector Performance

Throughout this blog, we have explored how conveyor design influences how a metal detector works in real-world food production environments. Belt materials, frame construction, vibration, product presentation, and electrical layout all play a role in determining what do metal detectors detect and what can a metal detector detect.

Even the most advanced food industry metal detectors or a high-end metal detector for food production line can underperform if the conveyor introduces mechanical instability, signal interference, or inconsistent product positioning. Proper attention to these details ensures detection sensitivity is maintained and contamination risks are minimized, reinforcing both compliance and brand protection.

The Importance of a System-Level Approach to Food Safety Inspection

One of the key takeaways is that effective metal detection is not just about selecting a high-quality detector—it requires a system-level approach. This means integrating the detector, conveyor, reject mechanisms, and control systems to work harmoniously.

Understanding how does a metal detector work in the context of the full production line allows manufacturers to optimize metal detector in food industry applications. A well-integrated system improves inspection reliability, reduces false alarms, and ensures food safety standards are consistently met across diverse product types and packaging formats.

Final Recommendations for Food Manufacturers Aiming to Reduce False Rejects and Improve Detection Reliability

To maximize the benefits of metal detector for food production line installations, food manufacturers should:

Select conveyor materials and components that minimize signal interference.

Ensure product stability and spacing for consistent presentation in the detection zone.

Match belt speed and detector capability to maintain adequate detection time.

Implement robust mechanical and electrical design to reduce vibration and noise.

Integrate reject mechanisms and control systems carefully, followed by professional commissioning.

By following these recommendations, manufacturers can enhance how the metal detector works, increase what can a metal detector detect, reduce false rejects, and maintain the highest levels of food safety and operational efficiency.

In essence, optimizing conveyor design is not just a mechanical consideration—it is a strategic investment in reliable metal detection, quality assurance, and consumer protection.

FAQ

Q: Why is conveyor design important for metal detector performance?

A: Conveyor materials, geometry, belt speed, vibration, and mechanical stability all directly affect how a metal detector works. Poor design can reduce sensitivity, create false positives, or mask contaminants, compromising food safety.

Q: How do vibration and electrical interference affect metal detection?

A: Conveyor vibration and improper grounding or electrical layout can distort detection signals. Stabilizing belts, using shielded cabling, and isolating motors reduce noise, improving what can a metal detector detect and overall inspection reliability.

Q: What are common mistakes in integrating conveyors and metal detectors?

A: Common errors include placing metal components near the detection head, inadequate straight runs, mismatched belt speed, and poor electrical grounding. Correcting these ensures consistent detection and reduces false rejects.