Introduction — Why Product Integrity Matters More Than Ever

In today’s fast-moving manufacturing landscape, product integrity has evolved from a technical requirement into a core pillar of brand reputation. Product integrity refers to a product’s ability to reach consumers in its intended form—safe, uncontaminated, compliant with regulations, and consistent in quality. Any failure in this chain, especially in industries like food, chemicals, pharmaceuticals, or cosmetics, can result in expensive recalls, legal penalties, and long-lasting damage to consumer trust.

The rise of global supply chains and high-speed automated production lines has made it more challenging to maintain this integrity. As production speeds increase, so does the risk of undetected contaminants. For food manufacturers in particular, foreign body contamination remains one of the top causes of product recalls worldwide. This is where food metal detectors, and broader metal detection in food packaging, have become essential tools. Understanding how does a metal detector work, what do metal detectors detect, and specifically how do metal detectors work in food industry has become vital knowledge for modern manufacturers.

Against this backdrop, metal detection technology is no longer optional—it is a foundational safeguard that ensures products remain safe, compliant, and trusted by consumers.

Define Product Integrity in Modern Manufacturing

Product integrity in modern manufacturing refers to the comprehensive assurance that each item leaving the production line is free from defects, contaminants, and inconsistencies. It means that every product aligns with its defined safety, quality, and regulatory standards. In industries such as food production, this includes ensuring that no unintended materials—such as metal shavings, machine fragments, or packaging debris—enter the final product.

The presence of metal contaminants is one of the most critical risks, and this is where the metal detector in food and metal detector for food industry play indispensable roles. By integrating sensitive detection systems directly into the line, manufacturers can eliminate foreign bodies before products reach consumers.

Product integrity also relies on understanding equipment capabilities. For example, questions like how deep do metal detectors go or what can a metal detector detect influence how manufacturers select the right inspection machine for their products, packaging formats, and production speeds.

In the context of today’s manufacturing realities, product integrity is no longer merely a quality control concept—it is a brand survival strategy.

Explain the Rising Pressure on Brands Due to Stricter Regulations and Consumer Expectations

Brands today operate in an environment of unprecedented scrutiny. Food safety regulations have tightened around the world, requiring manufacturers to follow strict HACCP, ISO, and industry-specific standards. Regulatory bodies demand traceability, inspection visibility, and documented risk mitigation strategies. A single missed contaminant can trigger recalls that cost millions of dollars, and more importantly, erode consumer trust.

At the same time, modern consumers are more informed—and more demanding—than ever before. Social media amplifies any quality issue instantly, turning local incidents into global reputation crises. Customers expect transparency, consistency, and safety. They want assurance that manufacturers use advanced technologies such as food metal detectors and metal detector for food processing to ensure the integrity of what they consume.

These pressures have forced brands to adopt technologies that minimize risk while maintaining high throughput. Understanding how does a metal detector work and integrating metal detection directly into processing and packaging lines is now viewed as essential for meeting both regulatory demands and customer expectations.

Introduce the Role of Metal Detection as a Core Safeguard in High-Speed Production Environments

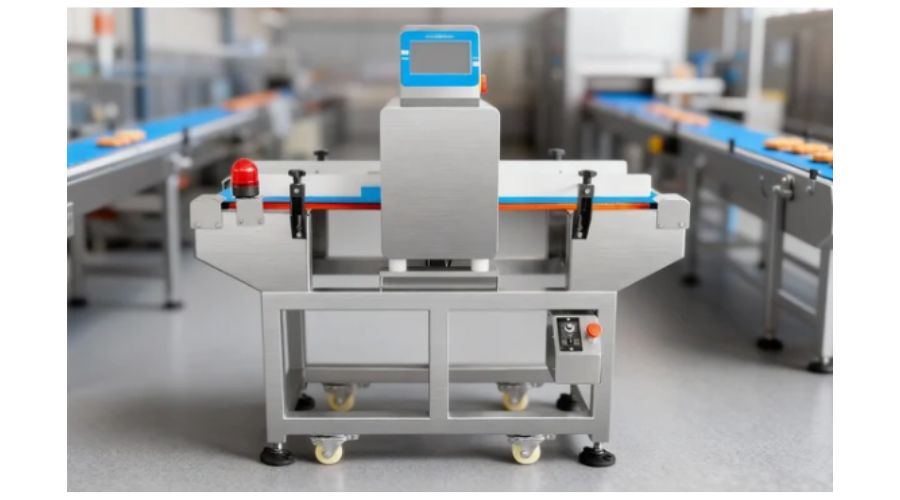

In high-speed production lines, where thousands of products pass through every hour, manual inspection is impossible. Automated metal detection has emerged as one of the most reliable and efficient safeguards to ensure product safety and consistency. Modern systems can detect ferrous, non-ferrous, and stainless-steel contaminants across a wide range of applications—even at high speeds and under challenging conditions.

Metal detection technology plays a vital role because it answers fundamental industry needs: what do metal detectors detect, how does a metal detector work, and more specifically how do metal detectors work in food industry. These systems use electromagnetic fields to identify metallic foreign bodies and trigger automatic rejection mechanisms without slowing down the production process. This makes them an ideal fit for high-speed environments where precision and efficiency are equally critical.

When integrated into food packaging or processing lines, metal detectors provide real-time protection, preventing contaminated products from reaching consumers. They help manufacturers maintain compliance, reduce waste, and protect both brand reputation and consumer health.

As production speeds continue to increase, the importance of reliable inspection solutions such as food metal detectors and metal detection in food packaging will only grow, solidifying metal detection as a core element of modern manufacturing quality assurance.

Challenges of Ensuring Quality on High-Speed Production Lines

Maintaining product safety and consistency on high-speed production lines has become increasingly complex. As automation enables faster throughput and higher productivity, the risk of foreign body contamination also rises. Manufacturers must now rely on advanced inspection technologies—such as food metal detectors, metal detector for food industry, and metal detection in food packaging—to maintain accuracy while keeping pace with modern production demands. Understanding how does a metal detector work and what do metal detectors detect is essential for overcoming these challenges.

High Throughput Increasing Risk of Undetected Contaminants

As production lines accelerate to meet growing demand, each product spends less time under inspection. High throughput significantly increases the likelihood that contaminants—such as metal fragments from machinery, broken processing tools, or packaging debris—can pass through undetected. Traditional systems often struggle to keep up, especially when thousands of items per hour move through the line.

This is why high-speed environments rely heavily on intelligent detection technology. Modern food metal detectors are designed to scan rapidly and consistently, even when product spacing is minimal. The faster the line runs, the more critical it becomes to understand how do metal detectors work in food industry and whether current inspection systems can handle high load conditions.

High-speed environments also raise practical questions, such as what can a metal detector detect or how deep do metal detectors go. The answers determine the system’s ability to capture contaminants inside dense products like meat blocks or packaged goods. Without the right technology in place, the probability of contaminants slipping through increases dramatically—putting consumer safety and brand integrity at risk.

Impact of Equipment Vibration, Product Variation, And Line Speed on Detection Accuracy

High-speed production environments introduce multiple real-world variables that directly impact metal detection performance. Equipment vibration, for example, can cause signal interference that masks or mimics the electromagnetic responses inspectors rely on. Product variation—such as moisture levels, density differences, and temperature changes—can also affect sensitivity. These challenges directly influence how reliable a metal detector in food system can be.

The higher the line speed, the greater the difficulty in maintaining stable detection accuracy. Even the most advanced detectors must compensate for product effect, signal noise, and shifting conveyor conditions. Manufacturers need to understand how does a metal detector work on a technical level to select equipment capable of stabilizing electromagnetic fields and filtering out false signals.

Modern inspection systems for food applications—such as metal detector for food processing machines—use sophisticated algorithms to balance these variables. They automatically adjust sensitivity and adapt to product characteristics in real time. This improves accuracy despite environmental challenges and ensures that even small contaminants fall within the scope of what do metal detectors detect.

Without these adaptive technologies, detection reliability would drop sharply under fast production speeds, making consistent quality nearly impossible to achieve.

Limitations of Manual Inspection and Traditional Quality Control Methods

Manual inspection has always been a weak link in quality assurance, and high-speed production lines make it even less viable. Human inspectors cannot match the precision, speed, or consistency required to identify microscopic metal fragments or hidden contaminants. Fatigue, distractions, and variability in human judgment further limit effectiveness.

Traditional quality control methods, such as visual checks or random sampling, provide only partial protection. They simply cannot identify internal contaminants or detect metal fragments embedded inside packaging—critical issues that modern food metal detectors are specifically designed to solve. Even understanding what can a metal detector detect highlights the limitations of manual methods; many contaminants are invisible to the human eye but are easily detected through electromagnetic sensing.

This gap makes advanced detection equipment indispensable. Modern systems using metal detection in food packaging technology can detect contaminants inside sealed bags, boxes, or airtight containers—tasks beyond the capability of manual inspection. Their ability to maintain accuracy regardless of speed is why they have become a permanent fixture in food safety programs worldwide.

As production lines become faster and products more varied, traditional inspection methods can no longer meet quality and safety standards. Only automated systems with a precise understanding of how do metal detectors work in food industry can consistently protect consumers and brands in today’s competitive landscape.

Key Advantages of Integrating Metal Detectors Into Fast Production Lines

As production environments continue to evolve toward higher automation and speed, integrating advanced food metal detectors has become essential for maintaining product safety and consistency. Modern systems used in the food metal detector sector provide more than just detection—they offer speed, stability, and protection that traditional inspection methods cannot match. Understanding how do metal detectors work in food industry helps manufacturers appreciate the critical value they bring to current high-speed workflows.

Real-Time Detection at Full Production Speed

One of the most significant advantages of integrating metal detectors into fast production lines is their ability to deliver real-time detection without slowing down throughput. Whether products are moving at hundreds of pieces per minute or passing through continuous conveyor flows, modern detection systems maintain precise sensitivity during full-speed operation.

This ability is based on a clear understanding of how does a metal detector work. Industrial detectors create a stable electromagnetic field and analyze disruptions caused by foreign metal contaminants. Because this process happens instantly, real-time inspection becomes possible even on the fastest automated lines.

Manufacturers frequently ask what do metal detectors detect or what can a metal detector detect, especially when dealing with highly processed or dense products. Today’s advanced systems detect a wide range of metals—ferrous, non-ferrous, and stainless steel—regardless of the production speed. For processors dealing with thick or layered products, questions like how deep do metal detectors go also matter. Modern high-sensitivity systems can detect metal deeply embedded within packaged meats, powders, liquids, or produce, ensuring safety even in challenging environments.

Automatic Rejection Systems Minimizing Operator Involvement

High-speed production lines cannot rely on manual rejection, especially when thousands of units pass through inspection points every hour. Integrated automatic rejection systems significantly reduce workforce burden while preventing contaminated products from continuing down the line.

These systems work seamlessly with metal detector in food setups to eject defective packages precisely and consistently. Depending on product type and line structure, rejection mechanisms may include air blasts, pushers, drop gates, or diverter arms. Because they operate automatically, the risk of human error is minimized.

Automatic rejection also ensures traceability. Pairing rejection logs with metal detection in food packaging technology provides a complete digital record of when and why a product was removed. This reduces the need for operator intervention while maintaining compliance with global food safety standards such as HACCP, BRC, and IFS.

For processors handling mixed product formats, automatic rejection is particularly valuable. Systems such as metal detector for food processing can adapt to various weights, shapes, and materials without constant manual adjustment, allowing uninterrupted high-speed operation.

Consistent Sensitivity Under Variable Product Conditions

In real production environments, products rarely behave identically. Moisture levels fluctuate, temperatures vary, packaging formats differ, and product density can change throughout the day. These variations—known as “product effect”—create noise that can reduce detection accuracy.

Modern metal detector for food industry systems are designed to compensate automatically for these variations. Using advanced signal processing algorithms, they learn the product signature and maintain consistent sensitivity even when conditions shift. This is a significant improvement over earlier generations of detection technology.

Understanding how do metal detectors work in food industry reveals how these systems distinguish between actual metal contaminants and natural product variations. By stabilizing electromagnetic fields and filtering out interference, metal detectors ensure reliable performance across:

Frozen or thawing products

High-salt or high-moisture foods

Multi-layer packaging

Temperature-changing environments

When combined with smart self-calibration, manufacturers achieve stable, repeatable detection—regardless of product or environmental fluctuations.

Reduction of Costly Recalls and Improved Brand Protection

Perhaps the most impactful advantage of integrating metal detectors into fast production lines is the long-term protection they offer manufacturers. Contaminant-related recalls are some of the most expensive and damaging events a brand can face. They involve product retrieval, compensation claims, legal liability, and loss of consumer trust.

Using technologies like food metal detectors and metal detection in food packaging minimizes the risk of contaminated products reaching consumers. Because modern systems detect even tiny metal fragments, they act as a final safety barrier before products are shipped.

Beyond direct cost savings, strong detection capabilities enhance brand reputation. When consumers trust that a manufacturer prioritizes safety, long-term loyalty grows. Many global brands highlight their use of advanced inspection equipment—such as metal detector in food systems—as part of their quality assurance story.

By understanding what can a metal detector detect and selecting the right system for specific product types, manufacturers can build a more reliable food safety program that reduces recalls, improves compliance, and strengthens consumer confidence.

Technology Innovations Improving Metal Detection Accuracy

As food safety standards grow increasingly strict, modern production environments demand inspection technologies that provide higher detection sensitivity, stronger stability, and better adaptability to complex products. Significant advancements in food metal detectors have reshaped the industry, enhancing both the accuracy and reliability of contaminant detection. Understanding how do metal detectors work in food industry highlights just how far the technology has progressed—especially in its ability to identify small, embedded, or hard-to-detect contaminants across a wide range of processed and packaged foods.

Multi-frequency and Dual-Signal Detection for Complex Products

Traditional single-frequency systems often struggled with products that have high moisture, high salt content, or temperature variations. These characteristics create “product effect,” which can mask or mimic metal signals. Modern systems address this challenge with multi-frequency and dual-signal detection, dramatically improving accuracy for difficult product categories.

Multi-frequency technology allows food metal detectors to transmit and analyze multiple signal wavelengths simultaneously. This is particularly useful when manufacturers need to understand what do metal detectors detect across different types of contaminants. For example, ferrous metals respond better to low frequencies, while non-ferrous and stainless steel contaminants may require higher frequencies. Using several frequencies at once increases the chances of identifying all metal types.

Dual-signal detection enhances this further by processing two separate signal pathways, helping the system differentiate between product effect and true contaminants. This innovation is especially beneficial in metal detection in food packaging, where foil packaging, dense meats, or large-format products can make contamination harder to detect.

With these technologies, manufacturers no longer need to ask how deep do metal detectors go or whether they can detect metals in complex environments. The improved signal clarity allows for deeper penetration and more accurate contaminant identification across even the most challenging applications.

Intelligent Product Learning to Reduce False Rejects

One of the most significant advancements in modern inspection systems is intelligent product learning. Older metal detectors relied heavily on manual adjustments to calibrate sensitivity for each product. Today, advanced systems automatically learn and store product characteristics, drastically reducing false rejects and improving production efficiency.

During product learning, the detector continuously scans multiple samples to understand their natural electromagnetic properties. This helps determine how does a metal detector work with real-world materials and packaging types. Once the detector establishes a stable product signature, it becomes much better at distinguishing between product effect and actual contamination.

This intelligence is essential for the metal detector for food industry, where products vary in shape, density, temperature, and composition. By understanding these variations, the system can maintain high sensitivity without triggering unnecessary rejections.

Product learning also makes detection more consistent across diverse product categories—from wet foods to frozen meats to powdered ingredients—ensuring that the detector always knows what can a metal detector detect and how to reject contaminants accurately.

Advanced Noise Filtering and Environmental Compensation

Production environments are full of variables: equipment vibration, electrical interference, air pressure changes, and temperature fluctuations. In the past, these factors often caused unstable readings or performance inconsistencies in metal detection systems. Today’s advanced noise filtering algorithms significantly enhance stability and accuracy by isolating the signals that matter.

Sophisticated digital filtering removes electromagnetic noise and interference, allowing detectors to maintain stable operation and high sensitivity even in demanding factory conditions. This filtering is crucial for ensuring accuracy in metal detector for food processing applications, where multiple machines operate simultaneously and electrical noise levels can be high.

Environmental compensation technology automatically adjusts to external changes, such as temperature shifts or humidity variations. These adjustments help maintain compliance with safety regulations while ensuring reliable performance throughout the production day.

By enhancing signal clarity, these innovations directly improve metal detector in food applications, enabling accurate detection even when environmental conditions are less than ideal.

Stainless-Steel Detection Improvements for Challenging Applications

Stainless steel contamination is one of the most difficult challenges in the food industry. Because stainless steel is non-magnetic and has low conductivity, older systems struggled to detect it reliably—especially inside foil packaging or dense products such as meats.

Modern advancements have greatly enhanced the ability of food metal detectors to identify stainless-steel fragments. Multi-frequency scanning, improved signal processing, and optimized coil design enable manufacturers to achieve higher sensitivity even when dealing with hard-to-detect materials.

This is especially important in metal detection in food packaging, where stainless steel from processing equipment can enter the product unintentionally. Understanding what do metal detectors detect helps manufacturers choose systems capable of identifying stainless steel at the smallest possible sizes—even when embedded deep inside the product.

With these improvements, high-risk products such as poultry, seafood, processed meats, ready-to-eat meals, and high-density food formats can be inspected with far greater accuracy.

Application Scenarios Across Industries

Metal detection technology is vital across multiple industries where product safety, compliance, and brand protection are essential. Understanding how does a metal detector work and what do metal detectors detect helps illustrate why different sectors rely on these systems to identify contaminants and ensure consumer safety. Below are the key application areas where modern metal detection plays a critical role.

Food Processing: Snacks, Meats, Dairy, Ready Meals

The food industry is the most widely recognized application area for metal detection systems. Modern food metal detectors are used extensively across snacks, meats, dairy products, and ready-to-eat meals to identify even the smallest metal fragments introduced during processing. Whether it’s cutting, mixing, slicing, or packaging, metal contamination can occur in many ways—making metal detector for food processing equipment indispensable.

In high-risk industries such as meat and poultry, manufacturers need to know how do metal detectors work in food industry to ensure effective screening. These systems detect ferrous, non-ferrous, and stainless-steel contaminants, helping companies maintain compliance with global food safety regulations.

Equally important is understanding what can a metal detector detect in different types of food. Dense products like cheese or ready meals require detectors with strong signal penetration, echoing the importance of how deep do metal detectors go when working with thick or complex food items.

Whether integrated into conveyor systems or used for packaged products, metal detector in food applications remain the cornerstone of modern food safety programs.

Pharmaceuticals: Tablets, Capsules, Powders

Metal detection technology is also a critical safeguard in pharmaceutical manufacturing. Tablets, capsules, and powders must be free of metal contaminants to ensure patient safety and regulatory compliance. Detectors are typically installed at tablet presses, capsule fillers, and powder transfer points.

Pharmaceutical lines require extremely high sensitivity because products are small and impurities must be detected at the smallest possible size. Knowing how does a metal detector work helps highlight the importance of coil design and signal processing in achieving such fine detection levels.

Because tablets and powders move at high speed, the system must distinguish between noise and real contamination—meaning manufacturers must understand what do metal detectors detect and how modern systems differentiate between product characteristics and foreign materials.

Even though pharmaceutical products aren’t food, many technologies used resemble those in food metal detectors, such as multi-frequency capability and automatic rejection mechanisms.

Packaging Lines: Foil Packaging, Vertical Form-Fill-Seal Systems

Packaging lines create their own unique challenges. Foil-sealed items, metalized films, and vertical form-fill-seal (VFFS) systems often complicate traditional metal detection because packaging materials can interfere with detection signals.

In these scenarios, metal detection in food packaging plays a critical role. Specialized systems using ferrous-in-foil technology or multi-frequency scanning ensure accurate detection despite packaging interference. This is especially important for snack foods, dairy items, sauces, and ready meals commonly sealed in foil.

Understanding how do metal detectors work in food industry helps explain how detectors adjust frequency and filtering to compensate for packaging effects, ensuring high accuracy even at maximum production speed.

For VFFS systems, metal detectors are installed directly after sealing to ensure contaminants are caught before palletizing or shipping. Their ability to adapt to rapidly changing product flow demonstrates what can a metal detector detect even in fast, automated environments.

Pet Food and Agricultural Products

Metal detection is equally essential in pet food and agricultural processing. Pet food—whether kibble, wet food, or treats—must meet strict safety standards similar to human food. Here, food metal detectors are used to inspect large volumes of high-density products, ensuring contaminants from equipment wear, grinding, or mixing are identified.

Agricultural products such as grains, nuts, seeds, and dried fruits often require metal detection before further processing or export. Their natural variability in size, moisture, and density means it’s important to understand how deep do metal detectors go when screening bulk materials.

Because these products are often dusty, irregular, and fast-moving, companies rely on advanced metal detector for food industry technologies to maintain sensitivity across changing product conditions.

Systems installed at belt conveyors, gravity-fall points, or bulk packaging lines help detect ferrous and non-ferrous contaminants, illustrating what do metal detectors detect in raw, unrefined materials.

Best Practices for Maximizing Detection Performance

Maximizing the performance of a food metal detector requires more than just choosing the right equipment. It involves strategic planning, routine verification, proper reject handling, and continuous staff training. These best practices help ensure compliance, protect consumers, and maintain the integrity of the production line. For manufacturers who often ask questions like “how does a metal detector work”, “how do metal detectors work in food industry”, or “what can a metal detector detect”, the following strategies provide a clear roadmap for optimizing detection results.

Strategic Placement of Detectors Along the Line

Proper detector placement is one of the most effective ways to improve overall foreign body control. Different stages of food production carry different risks, making placement a strategic decision rather than a simple technical installation.

Incoming Inspection

Placing food metal detectors at the raw material entry point helps prevent contaminants introduced through supply chains. This reduces downstream risks and prevents unnecessary product waste.

Processing Stage

Machinery such as slicers, grinders, and mixers can wear down over time. Installing a metal detector for food processing after high-risk equipment ensures early detection of metal fragments generated during mechanical operations. This placement also aligns with questions like “what do metal detectors detect” because it emphasizes detection of stainless steel, ferrous, and non-ferrous metals—all common in processing environments.

Final Packing

The last inspection point—often linked to metal detection in food packaging—is crucial for catching contamination introduced during packaging or handling. At this stage, manufacturers must consider product effect, packaging materials, and even the question “how deep do metal detectors go”, as larger or denser packages may influence detection depth.

By positioning a metal detector for food industry equipment at each critical control point, manufacturers create redundancy and greatly reduce the chance of contaminated products reaching consumers.

Regular Calibration and Validation with Test Pieces

No matter how advanced a system is, consistent calibration is essential for maintaining detection accuracy. Calibration ensures the detector performs consistently and answers the fundamental question “how does a metal detector work” in practice—not just in theory.

Best practices include:

Routine Validation: Use certified test pieces containing ferrous, non-ferrous, and stainless steel spheres to verify performance. This confirms what a metal detector can detect under real production conditions.

Frequent Sensitivity Checks: Perform checks at the start of each shift, during product changes, and after any machine adjustment.

Documentation: Record each validation result to meet industry standards such as HACCP, BRCGS, and IFS.

Adjust for Product Effect: Moisture, salt content, temperature, and product density can impact detection signals in a metal detector in food system. Adjusting sensitivity and frequency parameters helps maintain stable performance.

Regular calibration ensures that food metal detectors maintain optimal sensitivity and continue performing reliably over time.

Proper Reject Mechanism Selection: Air-Blast, Pusher, Drop Flap, Diverter

Detection alone is not enough—contaminated products must be removed from the line efficiently and accurately. The reject mechanism is a critical part of any metal detector for food industry system and plays an essential role in overall food safety.

Air-Blast Reject

Ideal for lightweight packaged products such as snacks or sachets. It works well with high-speed lines and pairs effectively with small-format food metal detector systems.

Pusher Reject

Suitable for heavier products that cannot be moved by air, such as meat trays or large cartons.

Drop Flap Reject

Best for bulk or free-flowing materials like powders and grains. It ensures precise isolation of contaminated product streams.

Diverter Reject

Used in continuous flow production, redirecting contaminated items to an alternative lane without stopping the line.

The right reject mechanism ensures the detection system functions as a complete, reliable control point—catching contaminants and guaranteeing no defective products move forward.

Staff Training and Quality Documentation

Even the most advanced systems require skilled operators who understand how do metal detectors work in food industry and how to manage them effectively. Human knowledge remains a critical component of high-performance foreign body detection.

Essential training topics include:

Basic Principles: Operators should understand how a metal detector works, including signal interpretation, product effect, and environmental factors.

Proper Equipment Operation: Training should cover changeovers, sensitivity adjustments, error response, and correct test procedures.

Reject System Handling: Staff must know how to verify correct operation of air-blast, pusher, and other reject mechanisms.

Recordkeeping: Accurate documentation ensures compliance during audits and maintains traceability in case of incidents.

A well-trained team ensures consistent operation, quick troubleshooting, and reliable quality control documentation—all essential for maximizing the performance of any metal detector for food industry system.

Future Trends: Smarter and Faster Metal Detection

The landscape of metal detector for food industry technology is evolving rapidly. Manufacturers are seeking solutions that are not only more sensitive but also smarter, faster, and more integrated. As production speeds increase and product variety grows, embracing future trends is essential to stay ahead in food safety and quality control.

AI-Based Adaptive Algorithms

Artificial intelligence (AI) is revolutionizing how do metal detectors work in food industry applications. Modern food metal detectors can now use adaptive algorithms to learn product characteristics, dynamically adjusting sensitivity for each batch. This reduces false rejects and improves overall line efficiency. For producers asking what can a metal detector detect, AI-enhanced detectors offer superior detection of ferrous, non-ferrous, and stainless steel contaminants across a wide variety of products, even those with challenging product effects.

IoT-Enabled Monitoring and Real-Time Analytics

Internet of Things (IoT) integration is another key trend shaping the future of metal detection in food packaging and processing. IoT-enabled food metal detectors can transmit real-time performance data to central dashboards, allowing quality managers to monitor throughput, detection events, and equipment status remotely. This not only answers how does a metal detector work at a systems level but also helps manufacturers predict maintenance needs and maintain continuous compliance.

Integration with Full-Line Inspection Platforms (X-Ray, Vision Systems)

Future metal detector for food processing systems are increasingly part of integrated inspection platforms. By combining X-ray inspection, vision systems, and metal detection in food packaging, manufacturers can achieve comprehensive contamination control in one line. Integrated systems allow operators to understand what do metal detectors detect in context with other inspection methods, ensuring maximum product integrity. This holistic approach reduces the risk of overlooked contaminants and simplifies line management.

Sustainability Impact: Lowering Food Waste Caused by False Rejects

Smarter food metal detectors directly contribute to sustainability. Traditional systems sometimes reject safe products due to false positives. AI-powered adaptive systems and precise reject mechanisms minimize unnecessary product waste. For production managers concerned with both safety and environmental impact, modern metal detector in food solutions help achieve both—protecting consumers while reducing food waste. Understanding how deep do metal detectors go and how sensitivity adjustments work ensures only true contaminants are removed, enhancing sustainability outcomes.

This section highlights the future of food metal detectors: smarter, faster, and more sustainable. By embracing AI, IoT, and integrated platforms, food processors can achieve superior contamination control while optimizing efficiency and environmental responsibility.

Conclusion — Building a More Reliable and Efficient Production Line

Ensuring product integrity is a top priority in today’s fast-paced manufacturing environment. Food metal detectors play a critical role in identifying contaminants before they reach consumers. By incorporating advanced metal detector in food technology, manufacturers can safeguard product quality, reduce risk, and maintain compliance with industry standards. Understanding how does a metal detector work and how do metal detectors work in food industry applications allows companies to deploy systems effectively along the production line.

Reinforce the Importance of Metal Detectors in Protecting Product Integrity

Metal detection is an essential component of modern quality assurance. Food metal detectors answer the critical question of what do metal detectors detect and what can a metal detector detect—from ferrous and non-ferrous metals to stainless steel. By installing metal detector for food processing systems at strategic points, companies ensure that potential hazards are caught early, maintaining consistent product integrity throughout production.

Emphasize Their Role in High-Speed Production Efficiency, Compliance, and Brand Trust

High-speed production lines demand reliable inspection solutions. Food metal detectors deliver real-time detection and automatic rejection, minimizing downtime and manual intervention. They also help manufacturers comply with strict regulations in the metal detection in food packaging sector. A robust metal detection system enhances brand trust, assuring customers that each product leaving the line meets the highest safety standards. Understanding how deep do metal detectors go can guide proper placement and calibration, ensuring maximum efficiency and coverage.

Encourage Companies to Adopt Advanced Metal Detection Solutions for Future-Proof Processing

To stay competitive and future-ready, companies should invest in advanced metal detector for food industry technologies. Innovations like multi-frequency detection, AI-based adaptive algorithms, and IoT-enabled monitoring allow food metal detectors to operate accurately under variable conditions, reduce false rejects, and provide actionable analytics. Adopting these solutions ensures that production lines remain efficient, compliant, and capable of protecting product integrity for years to come.

FAQ

Q1: How deep do metal detectors go when scanning products?

A1: Detection depth depends on product density, size, and packaging. High-sensitivity detectors can identify metal fragments embedded deeply inside packaged meats, powders, or multi-layer products.

Q2: What are best practices for maximizing metal detector performance?

A2: Strategic placement along the line, regular calibration, appropriate reject mechanisms, and staff training are key. Using test pieces and documenting results ensures reliable operation and regulatory compliance.

Q3: Can metal detectors be integrated with other inspection systems?

A3: Yes. Modern food metal detectors can be combined with X-ray and vision inspection systems, creating full-line contamination control and enhancing overall product integrity monitoring.