Introduction — Safeguarding Bakery Products from Metal Contamination

Overview of Bakery Industry Challenges: Growing Production Volume and Stricter Food Safety Regulations

The bakery industry is one of the fastest-growing sectors in the global food industry, driven by rising consumer demand for convenient, ready-to-eat, and premium bakery products. However, as production scales up, so does the complexity of maintaining consistent food safety standards. Automated production lines, high-speed packaging systems, and diverse ingredient sourcing all increase the risk of foreign object contamination, including metal fragments.

To comply with increasingly strict international food safety regulations, such as HACCP, BRC, and FDA standards, bakeries are now integrating advanced metal detector in food industry solutions into their production lines. These systems play a vital role in protecting both consumers and brand reputation by ensuring that every loaf of bread, cookie, or pastry that reaches the shelf is completely free from contamination.

Why Contamination Is Critical: Even Small Metal Fragments Can Lead to Recalls, Brand Damage, and Legal Risks

Metal contamination is one of the most serious threats in modern food production lines. Even a small piece of stainless steel wire or an aluminum shaving from machinery can cause physical harm to consumers or trigger widespread recalls. Such incidents not only result in financial losses but also damage a brand’s reputation and consumer trust.

Understanding what do metal detectors detect and what can a metal detector detect is essential in preventing these risks. In bakery applications, these devices are designed to identify ferrous, non-ferrous, and stainless steel contaminants that might enter products during mixing, baking, slicing, or packaging. Whether the contamination originates from a broken mixing blade or a packaging machine component, food industry metal detectors can detect it in real time, ensuring any compromised product is automatically removed from the line.

Purpose of the Article: Explain How Metal Detectors Protect Bakery Products and Ensure Contaminant-Free Production

This article aims to explain how does a metal detector work and why it’s a critical safeguard in bakery operations. In simple terms, how a metal detector works or how the metal detector works involves generating a magnetic field that identifies metallic particles within products passing through the detection tunnel. Once a contaminant is detected, the system automatically rejects the affected product, maintaining a contaminant-free production flow.

By understanding the working principles and applications of metal detector for food production line systems, bakeries can significantly enhance their quality assurance process. These detectors not only ensure compliance with food safety standards but also help producers maintain consumer confidence in their brand. In the following sections, we’ll explore how these systems operate, where they’re most effectively placed in bakery production, and how to choose the right metal detector for different product types.

Understanding Metal Contamination in Bakery Production

Common Sources of Metal Contaminants

In bakery production, metal contamination can occur at almost any stage — from raw ingredient processing to final packaging. Even with modern automation, mechanical components such as mixers, conveyors, and slicers pose potential contamination risks. Over time, wear and tear on equipment can cause tiny metal particles to break off and fall into the dough or finished product.

Common sources include:

- Raw material handling: Metal fragments may enter through contaminated flour, sugar, or other ingredients.

- Processing equipment: Blades, beaters, and conveyors can shed ferrous or stainless steel particles due to friction or vibration.

- Packaging systems: Fast-moving sealing or cutting machines can also produce small metallic residues.

These contaminants are often invisible to the naked eye, which is why food industry metal detectors are indispensable. Understanding what do metal detectors detect and what can a metal detector detect helps bakery manufacturers select appropriate inspection systems. In general, metal detector in food industry applications can identify ferrous metals (like iron), non-ferrous metals (such as copper or brass), and stainless steel, even in challenging environments like warm or moisture-rich baked goods.

By placing metal detector for food production line systems strategically—such as after mixing, baking, or packaging—manufacturers can prevent contaminated products from leaving the factory and maintain the highest level of food safety assurance.

Consequences of Metal Contamination

Even a single incident of metal contamination can have severe consequences for bakery producers. The most immediate risks include product recalls, financial losses, and damage to brand reputation. When contaminated products reach consumers, they can cause physical injuries, leading to lawsuits and regulatory penalties.

In addition to financial repercussions, contamination incidents can destroy consumer confidence in a brand that may have taken years to build. For companies operating under global food safety standards, one failed inspection or customer complaint can also result in production halts or loss of certification.

Understanding how a metal detector works is essential for preventing such crises. In essence, how the metal detector works or how does a metal detector work involves generating an electromagnetic field within a detection tunnel. When a metal object passes through, it disrupts the field, triggering a rejection signal. This quick and automated process ensures that every product leaving the line is free from metallic impurities.

Therefore, integrating reliable food industry metal detectors into bakery production not only prevents contamination but also protects a company’s long-term reputation and market competitiveness. By implementing robust detection systems and regular maintenance, bakeries can maintain consistent quality, meet international compliance standards, and provide consumers with safe, trustworthy products.

How Metal Detectors Work in Bakery Production

Core Detection Principle

Understanding how a metal detector works is fundamental to ensuring contaminant-free bakery production. At its core, a metal detector for food production line generates an electromagnetic field inside the detection tunnel. When a metallic object—whether ferrous, non-ferrous, or stainless steel—passes through, it disrupts this field. The detector senses the disruption and triggers a signal, often resulting in automatic rejection of the contaminated product.

Knowing what do metal detectors detect and what can a metal detector detect allows bakery operators to configure sensitivity levels accurately. This ensures that even tiny fragments from processing equipment or packaging materials are caught without generating unnecessary false alarms. Proper understanding of how the metal detector works is essential to maximize food safety and maintain consistent quality standards in bakery production.

Key Components of a Metal Detector

A typical metal detector in food industry consists of several critical components that work together to identify metallic contaminants efficiently:

Detection Coil/Tunnel: The area where products pass through and electromagnetic fields are generated.

Control Unit: Analyzes signals from the detection coil and determines if a contaminant is present.

Rejection Mechanism: Automatically removes contaminated products from the production line to prevent them from reaching consumers.

Conveyor or Feed System: Ensures smooth and continuous product flow for accurate detection.

By understanding how does a metal detector work, bakery operators can select equipment with appropriate coil sizes, sensitivity settings, and rejection systems. Modern food industry metal detectors also allow data logging, which supports traceability and compliance with regulatory standards.

Integration Points in Bakery Lines

For maximum effectiveness, metal detector for food production line systems must be strategically integrated into bakery operations. Common integration points include:

Post-mixing: Detect any metal fragments introduced with raw ingredients.

Post-baking: Ensure that metal contaminants from ovens or conveyor chains are caught.

Pre-packaging: Confirm that final products are free from metallic contamination before shipping.

Understanding how a metal detector works and the principles behind what can a metal detector detect helps operators position detectors where the risk of contamination is highest. Proper integration of food industry metal detectors enhances production line safety while maintaining efficiency and minimizing waste, ensuring that every batch meets strict food safety requirements.

Benefits of Metal Detection in Bakery Production

Enhanced Product Safety

Implementing a metal detector for food production line significantly enhances food safety by preventing metal contaminants from reaching consumers. Understanding how a metal detector works allows operators to accurately identify what do metal detectors detect—from ferrous to non-ferrous and stainless steel fragments. This proactive detection ensures that even tiny metallic particles introduced during ingredient handling or equipment wear are caught, reducing the risk of injuries or complaints. Effective use of food industry metal detectors guarantees that bakery products are consistently safe and reliable.

Compliance with Food Safety Standards

Bakery manufacturers are required to meet stringent regulatory standards, including HACCP and ISO certifications. By understanding how the metal detector works, companies can demonstrate proper placement and operation of metal detector in food industry systems. Knowing what can a metal detector detect and maintaining documented detection logs helps meet audit requirements and ensures traceability. Properly configured food industry metal detectors serve as a key tool in achieving and proving compliance, supporting the company’s commitment to food safety.

Improved Operational Efficiency

Modern food industry metal detectors are designed to integrate seamlessly with bakery production lines. Understanding how does a metal detector work allows operators to minimize false rejects while maintaining high throughput. Strategically using metal detector for food production line technology ensures that contaminated products are removed automatically without disrupting workflow. This combination of accurate detection and automation reduces waste, saves labor costs, and improves overall production efficiency.

Brand Protection and Customer Trust

Consumers increasingly prioritize safety and quality when choosing baked goods. By leveraging how a metal detector works, bakeries can prevent contamination incidents that may lead to recalls or reputational damage. Knowledge of what do metal detectors detect and what can a metal detector detect enables companies to consistently deliver safe, high-quality products. Properly utilizing metal detector in food industry systems not only protects the brand but also builds customer trust, reinforcing the bakery’s commitment to food safety and quality excellence.

Integration with Other Inspection Technologies

Metal Detection vs. X-Ray Inspection

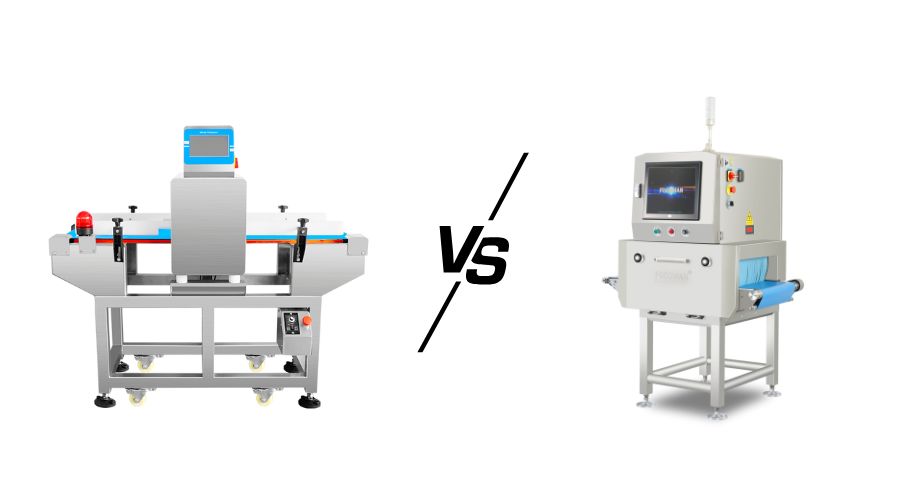

While metal detector in food industry systems are highly effective for identifying ferrous, non-ferrous, and stainless steel contaminants, they have limitations when detecting low-density foreign objects such as glass, stones, or plastic. Understanding how a metal detector works and what can a metal detector detect helps manufacturers decide when to complement metal detection with X-Ray inspection. By combining food industry metal detectors with X-Ray technology, bakeries can achieve comprehensive food safety coverage, detecting both metallic and non-metallic hazards and ensuring contaminant-free products.

Seamless Integration with Production Lines

Modern metal detector for food production line systems are designed for smooth integration with existing bakery lines. Knowing how the metal detector works allows operators to place detection points strategically to maximize efficiency without disrupting workflow. Food industry metal detectors can be paired with checkweighers, sorting machines, and X-Ray systems to create a fully automated quality control setup. This integration ensures continuous monitoring, minimal product loss, and real-time food safety traceability, while maintaining high production throughput.

Best Practices for Maintaining Reliable Metal Detection

Routine Calibration and Sensitivity Tests

To ensure that metal detector in food industry systems operate effectively, routine calibration and sensitivity testing are essential. Understanding how a metal detector works allows quality teams to verify that the system correctly identifies contaminants and maintains optimal detection thresholds. Regularly testing what do metal detectors detect and what can a metal detector detect helps minimize false rejects while ensuring that no hazardous metal fragments pass through the metal detector for food production line. These practices are fundamental for sustaining consistent food safety standards.

Proper Staff Training

Even the most advanced food industry metal detectors rely on skilled operators for optimal performance. Staff must be trained on how the metal detector works, including understanding detection alerts, system settings, and the types of contaminants the equipment can identify. Educating personnel about how does a metal detector work ensures accurate monitoring and response during production. Well-trained operators help maximize the reliability of metal detector for food production line systems, maintaining both product safety and operational efficiency.

Continuous Improvement

Maintaining high-performance metal detector in food industry systems requires ongoing evaluation and continuous improvement. By analyzing detection data and performance metrics, manufacturers can refine processes and adjust system settings based on how the metal detector works. Implementing feedback loops and process enhancements ensures that what do metal detectors detect and what can a metal detector detect remain aligned with evolving food safety standards. Continuous improvement also reduces operational risks and supports consistent compliance across bakery production lines.

Conclusion — Building a Safer Bakery Production Line

Metal Detectors Are Essential for Eliminating Metallic Hazards in Bakery Production

Metal detectors for food production line are a critical component of any bakery’s food safety strategy. By understanding how a metal detector works and monitoring what do metal detectors detect, bakeries can prevent metallic contaminants from reaching consumers. Whether it is fragments of stainless steel, iron, or aluminum, employing reliable metal detector in food industry systems ensures that all baked goods remain safe and compliant with industry standards. This proactive approach significantly reduces the risk of recalls and protects both the brand and the consumer.

With AI Technology, Multi-frequency Detection, And Automated Traceability, Bakeries Can Ensure Contaminant-Free Products

Modern food industry metal detectors incorporate advanced technologies such as AI algorithms, multi-frequency detection, and automated data logging. These features enhance the understanding of how the metal detector works and improve the system’s ability to detect diverse contaminants — essentially answering what can a metal detector detect. With integrated traceability, every product’s inspection history can be recorded, allowing quality teams to respond quickly to any potential issue and maintain a high standard of food safety across the production line.

Investing in Advanced Metal Detection Not Only Meets Compliance — It Builds Consumer Confidence and Brand Value

Beyond regulatory requirements, deploying advanced metal detector for food production line solutions strengthens consumer trust and enhances brand reputation. By demonstrating a commitment to food safety and leveraging the latest in food industry metal detectors, bakeries signal that product quality and customer protection are top priorities. Understanding how the metal detector works and ensuring proper operation helps companies reduce risks, improve efficiency, and reinforce the value of their brand in the competitive bakery market.

FAQ

Q1: How often should metal detectors be calibrated?

A1: Routine calibration and sensitivity tests should be conducted regularly to ensure accurate detection and maintain food safety.

Q2: Why is staff training important for metal detection?

A2: Proper training ensures operators understand how the metal detector works, interpret alerts correctly, and maintain consistent quality control.

Q3: What are the benefits of using metal detectors for bakery products?

A3: Benefits include enhanced product safety, compliance with food safety standards, operational efficiency, and brand protection.