Introduction

Overview of Multi-Lane Production Lines in Modern Manufacturing

In today’s fast-paced manufacturing environment, multi-lane production lines have become the standard for high-throughput industries such as food processing, packaging, and pharmaceuticals. These systems are designed to simultaneously process multiple product streams, significantly boosting production efficiency and output. However, with speed and scale comes complexity, especially in maintaining consistent quality control across every lane. This is where advanced inspection technologies, such as the X-Ray inspection system, play a vital role in managing risks and ensuring consistent product integrity.

The Increasing Need for High-Precision Food X-Ray Inspection

As consumer demand for safe, high-quality food continues to rise, manufacturers must adhere to ever-stricter regulations and quality standards. In multi-lane settings, any lapse in inspection accuracy could lead to contaminated or defective products reaching the market. This has elevated the need for food X-Ray inspection systems that offer not only high sensitivity but also exceptional lane-by-lane precision.

Modern X-Ray inspection equipment is now expected to identify foreign objects, such as glass, metal, and bone fragments, even in high-speed operations. Additionally, it must maintain detection accuracy without compromising throughput—making high-precision X-Ray technology a core requirement in quality control strategies.

Role of X-Ray Inspection Machines in Ensuring Product Consistency and Safety

To address the challenges of multi-lane inspection, manufacturers are turning to X-Ray inspection machines equipped with lane-specific scanning capabilities and AI-powered image processing. These machines can inspect individual product lanes simultaneously, ensuring uniform detection results across all lines without overlaps or blind spots.

Whether it’s identifying contaminants, verifying fill levels, or ensuring seal integrity, modern X-Ray inspection systems bring consistency and reliability to multi-lane operations. Their ability to deliver real-time analysis and automatic rejection of defective items allows manufacturers to reduce waste, protect brand reputation, and meet global food safety standards.

By integrating advanced X-Ray inspection equipment into multi-lane production lines, companies can ensure that every item—regardless of lane—is subjected to the same rigorous quality checks, thus maintaining both safety and consumer trust.

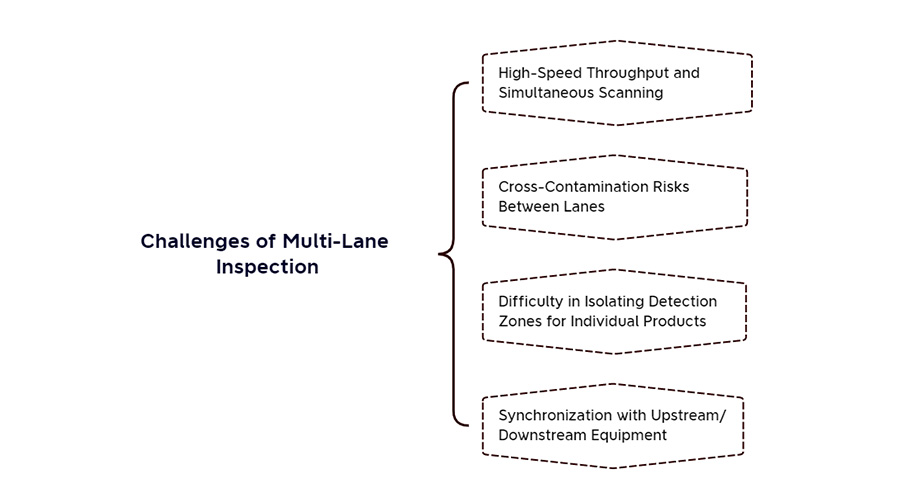

Challenges of Multi-Lane Inspection

High-Speed Throughput and Simultaneous Scanning

Multi-lane production lines are designed to maximize output by processing several lanes of products concurrently, often at very high speeds. This creates a significant challenge for X-Ray inspection systems, which must perform rapid, simultaneous scanning without compromising detection accuracy. The X-Ray inspection equipment deployed must be capable of capturing clear images across multiple lanes in real time, ensuring no product is missed during the inspection process.

Maintaining precision under these conditions requires advanced detector technology and powerful image processing algorithms within the X-Ray inspection machine. Without such capabilities, fast-moving products can lead to blurred images or missed contaminants, reducing the overall effectiveness of food safety controls.

Cross-Contamination Risks Between Lanes

In multi-lane setups, the proximity of different product streams increases the risk of cross-contamination, which can complicate inspection and product safety assurance. Traditional food X-Ray inspection machines may struggle to differentiate contaminants when products from adjacent lanes overlap or when foreign objects appear near lane boundaries.

Effective X-Ray inspection systems must incorporate sophisticated lane separation techniques and high-resolution imaging to accurately isolate each lane’s product profile. This prevents false detections caused by material overlap and helps maintain high detection reliability essential in food manufacturing environments.

Difficulty in Isolating Detection Zones for Individual Products

Isolating detection zones is critical for ensuring that each product is inspected independently, especially in multi-lane lines where products move in close succession. However, this task becomes challenging when products vary in size or shape, or when the conveyor speeds fluctuate.

Advanced X-Ray inspection machines are equipped with dynamic zone detection and customizable algorithms to overcome these difficulties. Such X-Ray inspection equipment can automatically adjust the detection zones in real time, ensuring each product receives focused scanning and contaminant analysis. This capability is vital for minimizing false positives and maintaining inspection accuracy across diverse food product types.

Synchronization with Upstream/Downstream Equipment

Integration and synchronization with other production line equipment is another complex challenge for multi-lane X-Ray inspection systems. The inspection process must be precisely timed with upstream sorting or filling machines and downstream rejecters or packagers.

Seamless communication protocols and control interfaces in modern X-Ray inspection equipment allow for real-time coordination across the entire production line. This synchronization minimizes bottlenecks and ensures that rejected products are efficiently removed without disrupting overall throughput, ultimately maintaining smooth operation and product quality consistency.

Key Technologies Enabling High Accuracy

Achieving high accuracy in multi-lane production lines relies heavily on cutting-edge technologies embedded within modern X-Ray inspection systems. These technological advancements address the unique challenges posed by simultaneous scanning of multiple lanes, ensuring precise contaminant detection without compromising production speed. Below, we explore the key technologies that enable superior performance in food X-Ray inspection applications.

High-Resolution Detectors

At the core of any advanced X-Ray inspection machine lies the detector technology. For multi-lane inspection, high-resolution detectors are essential to differentiate products and contaminants across adjacent lanes with clarity.

Modern X-Ray inspection equipment employs sophisticated sensors with enhanced pixel density that capture detailed images specific to each lane. This lane-specific detection allows the system to isolate foreign objects even in dense product flows, where materials may be tightly packed or overlapping.

Higher pixel density translates directly into improved defect identification, as smaller or low-contrast contaminants become visible in the captured images. This capability is especially crucial in food processing lines where delicate products such as seafood, dairy, or processed meats require precise inspection to ensure consumer safety.

By integrating high-resolution detectors, X-Ray inspection systems maintain consistent accuracy across all lanes without sacrificing throughput, even at high line speeds.

Multi-Lane Calibration Algorithms

Beyond hardware, intelligent software plays a pivotal role in maintaining accuracy across multiple lanes. Multi-lane X-Ray inspection systems leverage advanced calibration algorithms designed to dynamically adjust sensitivity settings on a per-lane basis.

These algorithms analyze real-time data to correct for lane position variances and product differences such as size, density, or packaging material. This adaptability allows the X-Ray inspection machine to fine-tune its detection parameters instantaneously, minimizing false positives and false negatives.

Real-time calibration is critical in complex food manufacturing environments where product variations are common. Whether processing differently shaped items or shifting production speeds, the system can compensate automatically, ensuring reliable contaminant detection without manual intervention.

This intelligent software approach not only enhances detection performance but also streamlines operation, reducing downtime associated with manual recalibration.

Beam Collimation and Shaping

To achieve precise inspection in multi-lane configurations, controlling the X-Ray beam itself is vital. Beam collimation and shaping technologies help prevent signal overlap between adjacent lanes, which can cause ambiguous imaging and reduce detection reliability.

By narrowing and focusing the X-Ray beam specifically onto each lane, the X-Ray inspection equipment minimizes interference and cross-talk between neighboring product streams. This targeted irradiation enhances image contrast and sharpness within individual lanes, allowing for clearer identification of foreign objects.

Furthermore, beam shaping techniques optimize the energy distribution of the X-Ray source, improving penetration and contrast tailored to the product type and packaging. This ensures that even low-density contaminants are detected without excessive exposure that could damage sensitive products.

Incorporating advanced beam collimation and shaping features in food X-Ray inspection systems leads to higher inspection accuracy, fewer false alarms, and better overall product quality assurance.

Intelligent Image Processing

In the rapidly evolving landscape of food safety, X-Ray inspection systems have become indispensable tools for ensuring product quality and contaminant detection. The integration of intelligent image processing technologies, especially AI-driven image recognition, significantly enhances the capabilities of modern X-Ray inspection machines used in food production.

Integration of AI-Driven Image Recognition

AI-driven image recognition is transforming how food X-Ray inspection equipment analyzes products. Traditional X-Ray systems relied heavily on preset thresholds and static detection parameters, which could limit their ability to adapt to product variations or new contaminants. Today, AI algorithms enable X-Ray inspection machines to “learn” from vast amounts of image data, recognizing complex patterns and subtle anomalies that might otherwise be missed.

This integration allows X-Ray inspection systems to automatically differentiate between acceptable product characteristics and true contaminants, improving both speed and accuracy. The AI models continuously refine their detection logic, ensuring that the inspection process adapts to changing product lines and environmental factors without manual recalibration.

Real-Time X-Ray Inspection System Analysis for Shape, Density, and Contaminants

One of the key advantages of intelligent image processing in X-Ray inspection equipment is the real-time analysis of multiple product attributes such as shape, density, and the presence of foreign objects. The food X-Ray inspection system examines these features simultaneously, enabling it to detect not only traditional contaminants like metal, glass, or bone but also anomalies related to product integrity, such as missing components or deformities.

By processing these variables in real time, the X-Ray inspection machine can provide immediate feedback to the production line, allowing for quick rejection of defective or contaminated items. This rapid analysis is critical in high-speed, multi-lane production lines where accuracy cannot be sacrificed for throughput.

Reducing False Positives in High-Volume Operations

False positives—where safe products are mistakenly flagged as defective—pose a significant challenge in high-volume food processing. Excessive false alarms can cause unnecessary waste, slow down production, and increase operational costs.

Modern X-Ray inspection systems equipped with AI-powered image processing drastically reduce false positive rates. By learning from previous inspections and continuously updating detection criteria, the X-Ray inspection equipment can better distinguish between harmless variations and genuine threats. This improvement leads to smoother production workflows, less product loss, and greater confidence in the inspection results.

In conclusion, the integration of intelligent image processing into food X-Ray inspection machines elevates detection accuracy, enhances operational efficiency, and supports stringent food safety standards. As technology continues to advance, these smart inspection systems will play an increasingly vital role in protecting consumers and maintaining product quality across the food industry.

System Design for Multi-Lane Environments

In high-throughput manufacturing, especially in the food industry, multi-lane production lines are essential for maximizing productivity. To maintain precision and safety across each lane, the X-Ray inspection system must be intelligently designed to handle simultaneous product flows without compromising on detection accuracy. Modern X-Ray inspection equipment achieves this through several critical design elements.

Modular Conveyor Layout with Lane Dividers

The foundation of an effective multi-lane X-Ray inspection machine lies in its modular conveyor design. These systems are equipped with clearly defined lane dividers that isolate individual product streams, ensuring no overlap or interference between items. This layout allows the X-Ray inspection system to treat each lane independently, which is particularly important for food X-Ray inspection where product consistency and cleanliness are paramount.

Modular conveyors also offer the flexibility to adjust lane configurations based on product size and production volume, making the X-Ray inspection equipment highly adaptable for diverse manufacturing environments.

Customizable Inspection Zones in X-Ray Inspection Equipment

Advanced X-Ray inspection systems feature customizable detection zones that align precisely with the layout of the conveyor. Each inspection zone can be individually tuned to accommodate the product type, expected contaminant profiles, and inspection sensitivity required for each lane.

This level of customization enhances the accuracy of the X-Ray inspection process, enabling the system to detect even minute foreign objects—like glass, bone, or metal—in specific sections without false triggering. This is particularly beneficial for food X-Ray inspection, where precision is critical to maintaining consumer safety and brand reputation.

Synchronization with Rejectors for Lane-Specific Product Removal

An essential component of multi-lane X-Ray inspection machines is their ability to integrate seamlessly with lane-specific rejectors. Once a contaminant or defect is detected in a specific lane, the system signals the corresponding reject mechanism to remove the affected product without disturbing the others.

This targeted rejection capability minimizes waste and keeps the production line running smoothly. By combining accurate detection with intelligent removal, modern X-Ray inspection equipment ensures both safety and efficiency in high-speed, multi-lane production environments.

Benefits of Accurate Multi-Lane X-Ray Inspection

In today’s high-throughput manufacturing environments, especially in food and pharmaceutical sectors, efficiency must go hand in hand with precision. Multi-lane X-Ray inspection systems have emerged as a game-changer, enabling producers to maintain uncompromising quality standards while maximizing throughput. This article explores the key benefits of implementing accurate multi-lane X-Ray inspection equipment.

Increased Productivity Without Sacrificing Quality

One of the most significant advantages of modern X-Ray inspection machines designed for multi-lane operations is the ability to inspect multiple product streams simultaneously. Whether inspecting packaged snacks, baked goods, or meat products using food X-Ray inspection technologies, manufacturers can process more units per minute without compromising the accuracy of contamination detection.

Each lane is treated as an independent inspection channel, ensuring that foreign objects such as metal, bone fragments, glass, or stones are accurately identified—even in fast-paced production environments. This capability allows companies to scale production while preserving the high standards enforced by regulatory bodies and consumer expectations.

Centralized Control with Lane-by-Lane Analysis

Advanced X-Ray inspection systems feature centralized control interfaces that allow operators to monitor and adjust inspection parameters in real time for each lane. This lane-by-lane analysis capability ensures that different product types or packaging formats can be processed concurrently without interference.

For example, a multi-lane X-Ray inspection machine used in a meat processing facility might inspect different cuts of meat simultaneously, each requiring different density thresholds for accurate detection. By isolating each lane’s configuration, the X-Ray inspection equipment guarantees individualized performance while maintaining overall system efficiency.

Minimizing Waste Through Precise Detection and Rejection

Accurate X-Ray inspection not only improves quality assurance but also reduces waste. In traditional systems, false positives can result in entire batches being rejected unnecessarily. However, modern food X-Ray inspection machines with lane-specific rejectors allow only the affected product to be removed, preserving good items in adjacent lanes.

This level of precision helps reduce material waste, packaging waste, and rework costs, contributing to both economic and environmental sustainability. Over time, the savings generated from reduced false rejections and improved efficiency make multi-lane X-Ray inspection systems a highly cost-effective investment.

Future Trends in Multi-Lane X-Ray Inspection

As the manufacturing landscape embraces Industry 4.0, X-Ray inspection systems are evolving beyond basic foreign body detection. In high-throughput environments like food and pharmaceutical packaging lines, especially those with multi-lane setups, the future of X-Ray inspection is being shaped by intelligent automation and data-driven decision-making. Below are key trends redefining the future of X-Ray inspection equipment in multi-lane production.

AI-Enhanced Decision-Making Per Lane

Traditional X-Ray inspection machines apply a uniform set of detection rules across all product lanes. However, the next generation of systems leverages artificial intelligence (AI) to make real-time, lane-specific decisions. These smart X-Ray inspection systems can analyze product density, shape, and composition with adaptive thresholds, learning from historical inspection data. In food X-Ray inspection, for instance, the system can distinguish between bone fragments in meat and benign calcium deposits, reducing false positives without compromising safety.

Integration with Factory MES/ERP Systems

To ensure full traceability and production efficiency, modern X-Ray inspection equipment is increasingly integrated into factory-level Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) platforms. This integration allows multi-lane X-Ray inspection machines to provide real-time inspection data tied to specific batches, shifts, and packaging lines. For industries like pharmaceuticals and high-speed food X-Ray inspection, this connectivity supports compliance, process transparency, and rapid decision-making based on centralized data.

Predictive Analytics for Lane-Specific Maintenance

Predictive maintenance is a game-changer for multi-lane production. By monitoring lane-specific performance metrics such as reject rates, belt speed variations, and image noise, advanced X-Ray inspection systems can forecast potential failures or maintenance needs before downtime occurs. This proactive approach ensures each lane in a high-speed X-Ray inspection machine operates at peak efficiency and accuracy, extending equipment lifespan while minimizing unexpected halts.

Conclusion: Embracing the Future of Multi-Lane X-Ray Inspection

The Growing Importance of Accurate, Lane-Specific X-Ray Inspection Systems

In today’s fast-paced food and pharmaceutical production lines, X-Ray inspection systems are no longer a luxury—they are a necessity. Especially in high-speed, multi-lane environments, the ability to detect contaminants or defects on a per-lane basis ensures both safety and compliance. Accurate, lane-specific X-Ray inspection capabilities reduce false positives, improve overall yield, and maintain consumer trust. As product variety and packaging complexity increase, advanced X-Ray inspection machines designed for multi-lane analysis will become the backbone of modern quality control operations.

How Technology Is Reshaping Food Quality Control in High-Speed, Multi-Lane Environments

Smart technologies are fundamentally reshaping how manufacturers approach food X-Ray inspection. Lane-by-lane data collection, AI-powered detection algorithms, and seamless integration with MES/ERP systems are allowing real-time decisions that optimize both efficiency and quality. Advanced X-Ray inspection equipment enables manufacturers to handle diverse product types—whether it’s detecting bones in meat, checking fill levels in snacks, or verifying tablet presence in blister packs—all in a single, unified platform. These innovations ensure that each lane operates independently yet synchronously, resulting in a truly adaptive inspection workflow.

Final Thoughts on Selecting the Right X-Ray Inspection Machine for Complex Production Setups

Choosing the right X-Ray inspection machine depends on multiple factors: product type, lane configuration, detection requirements, and system scalability. Manufacturers should look for X-Ray inspection systems that offer high-resolution detectors, smart rejection mechanisms, AI-based classification, and compatibility with various packaging formats. Most importantly, the system should support centralized management with lane-level customization—critical for large-scale food X-Ray inspection applications.

As the industry evolves, investing in intelligent, multi-lane X-Ray inspection equipment will not only ensure regulatory compliance but also deliver long-term operational excellence. From snacks to pharmaceuticals, and from bakery lines to blister packaging, the future of inspection is precise, adaptive, and lane-specific.

FAQ

Q: How do multi-lane X-Ray inspection systems increase productivity?

A: By inspecting several lanes simultaneously, these systems improve line speed and reduce bottlenecks. Operators can monitor all lanes from a centralized interface, streamlining quality control without compromising accuracy.

Q: What industries benefit most from multi-lane X-Ray inspection equipment?

A: Industries such as food, pharmaceuticals, and packaging—especially those with high-speed, multi-product lines—benefit significantly. Food X-Ray inspection is particularly enhanced in applications like snack foods, ready meals, and confectionery.

Q: What should be considered when selecting an X-Ray inspection machine for a multi-lane setup?

A: Key factors include the number of lanes, product type and size, inspection speed, detection resolution, AI capabilities, ease of integration, and service support. Choosing a system that balances accuracy and flexibility is crucial.