Introduction

Maintaining hygiene and water resistance is critical in food processing environments, especially where washdowns and humidity are common. In such settings, standard equipment can easily fail or introduce contamination risks. That’s where waterproof and hygienic designs in X-Ray inspection systems become essential. These systems are not only crucial for detecting contaminants but must also withstand wet and harsh environments to ensure long-term reliability and food safety. Modern X-Ray inspection equipment designed for wet areas is built with these needs in mind.

Importance of Hygiene and Water Resistance in Food Processing Environments

Food production lines—especially those handling meat, seafood, dairy, or ready-to-eat meals—often require frequent high-pressure washdowns. Without proper waterproofing, equipment is vulnerable to water ingress, leading to system failures and hygiene breaches.

A food X-Ray inspection machine operating in such an environment must be designed with waterproof seals, corrosion-resistant materials, and smooth surfaces to prevent bacterial buildup. A hygienic design not only ensures compliance with sanitation standards but also improves the longevity and performance of X-Ray inspection equipment.

Overview of X-Ray Inspection Systems in Wet Production Lines

X-Ray inspection systems are widely used in wet production lines to detect physical contaminants such as bone, metal, glass, and stone in fluid or semi-fluid food products. However, in moist or washdown environments, traditional systems without waterproofing may suffer from frequent breakdowns or safety hazards.

Modern X-Ray inspection machines tailored for wet conditions often feature high IP ratings (such as IP66 or IP69K), stainless steel enclosures, and sloped surfaces to prevent water pooling. These enhancements ensure that the system maintains high detection sensitivity and stability, even after multiple cleanings or under high humidity.

By combining smart design with durable materials, these food X-Ray inspection systems provide consistent performance and reduce downtime, making them a smart investment for processors aiming to improve food quality.

The Challenges of Wet and Harsh Environments

In modern food manufacturing—particularly in seafood, meat, and dairy sectors—wet, high-humidity, and chemically aggressive environments are a daily reality. These production lines require constant sanitation to comply with strict food safety standards, leading to frequent washdowns and high exposure to moisture. While this is vital for hygiene, it also creates a uniquely harsh operational setting for sensitive electronics and detection technologies, such as X-Ray inspection systems.

Operating under such conditions demands more than just advanced detection capabilities—it requires X-Ray inspection equipment that is engineered for resilience, durability, and hygiene compliance. Without this, equipment failures, production halts, and compromised food quality become inevitable risks.

Common Environmental Risks: Water Ingress, Condensation, Corrosion

One of the most serious threats to X-Ray inspection machines in wet production zones is water ingress. If even a small amount of moisture breaches the machine’s housing, it can lead to electrical shorts, system malfunctions, and even total failure of the inspection unit. Over time, undetected ingress may compromise internal circuitry, rendering expensive X-Ray inspection equipment unusable.

Condensation is another insidious problem—especially when equipment is exposed to fluctuating temperatures due to cleaning cycles or changes in ambient air. Internal fogging can obscure imaging sensors, reducing detection clarity and increasing the risk of false negatives or undetected contaminants. In precision-dependent systems like food X-Ray inspection, this significantly undermines food safety.

Then there’s corrosion—a slow but relentless enemy. Equipment installed in seafood or meat processing plants is exposed to salt, blood proteins, and acidic residues. Without robust, corrosion-resistant components and food-safe coatings, the structural integrity of an X-Ray inspection system can degrade over time, leading to higher maintenance costs, unexpected breakdowns, and shortened service life.

These environmental challenges highlight the need for X-Ray inspection equipment that not only detects threats in food products—but also resists threats from the surrounding environment.

Impact on Food X-Ray Inspection Machine Lifespan and Accuracy

Environmental stress doesn’t just affect hardware longevity—it directly impacts inspection accuracy and operational reliability. When gaskets, seals, or enclosures begin to fail, moisture or chemical vapors may penetrate the machine’s detection chamber. This can cause blurry images, loss of sensitivity, and increased rates of false positives or missed contaminants.

In critical applications such as food X-Ray inspection, even a momentary lapse in accuracy can result in contaminated products reaching consumers. The consequences range from brand reputation damage to expensive product recalls, regulatory violations, and even legal liability.

A rugged and properly sealed X-Ray inspection machine, designed for wet environments, can significantly extend operational life while maintaining optimal inspection performance. Features such as IP66 or IP69K ingress protection, stainless steel enclosures, and non-corrosive internal materials are no longer optional—they are essential.

Regular, unscheduled maintenance caused by water damage not only affects uptime but also disrupts production flow. In contrast, reliable, water-resistant X-Ray inspection systems can reduce downtime, lower long-term maintenance costs, and ensure consistent, high-quality food X-Ray inspection output.

Stringent Hygiene Standards in Industries Like Seafood, Meat, and Dairy

In high-risk industries, where contamination control is paramount, equipment must go beyond basic durability. Food X-Ray inspection machines must also adhere to rigorous hygiene standards set by authorities such as the FDA, USDA, and EU food safety regulators.

To meet these demands, modern X-Ray inspection systems are designed with hygienic principles in mind. This includes smooth, angled surfaces that prevent standing water, easy-access panels that allow for thorough cleaning, and materials that are resistant to both microbial growth and cleaning chemicals. Welded seams and minimal crevices eliminate bacterial harborage points, ensuring full compliance with sanitary design standards.

The ability to withstand daily high-pressure washdowns—often with caustic or chlorine-based cleaners—makes hygienic design a non-negotiable feature. Furthermore, compliance with international standards such as 3-A, EHEDG, or NSF is a critical benchmark for manufacturers selecting inspection systems for wet environments.

By combining waterproof integrity with hygienic construction, advanced X-Ray inspection equipment helps food producers avoid contamination risks, reduce product recalls, and maintain consumer trust in the safety and integrity of their food products.

Waterproof Design: Shielding the Core Technology

In wet and washdown-heavy food processing environments, the reliability and longevity of an X-Ray inspection system hinge significantly on its waterproof design. These environments are especially demanding in sectors such as seafood, meat, dairy, and ready-to-eat meals, where hygiene requirements are enforced through rigorous, high-pressure cleaning protocols. Without proper protection, sensitive components inside an X-Ray inspection machine can become vulnerable to moisture, chemicals, and temperature shifts.

Therefore, integrating waterproofing and hygienic design into the core architecture of food X-Ray inspection equipment is not just a value-added feature—it is a critical necessity for safety, compliance, and production continuity.

IP Ratings and Their Significance (e.g., IP66, IP69K)

The Ingress Protection (IP) rating system provides an internationally recognized standard for evaluating how well an X-Ray inspection machine is sealed against intrusion from solid particles and liquids. In the context of food X-Ray inspection, these ratings help food manufacturers determine which machine is appropriate for washdown zones or cleanroom installations.

IP66 protection means the system is dust-tight and resistant to powerful water jets from any direction. This is suitable for most general food processing areas.

IP69K, one of the highest possible ratings, certifies that the X-Ray inspection equipment can withstand high-pressure, high-temperature water jets used in sanitation processes, often exceeding 80°C at close range.

In food manufacturing facilities, where sanitation crews may perform multiple cleanings per shift, selecting an X-Ray inspection system with IP66 or IP69K certification ensures that the equipment will continue to operate reliably without the risk of water damage or contamination. These ratings are particularly crucial in maintaining consistent food quality and meeting global food safety regulations.

Sealed Cabinet Structures and Separated Compartments

The physical structure of a waterproof X-Ray inspection system is engineered to create multiple protective layers. Modern designs incorporate fully sealed stainless steel enclosures, which are resistant to corrosion, cleaning agents, and temperature-induced expansion. This external sealing ensures that no moisture or dust can penetrate the inner core, even during intensive washdowns.

Additionally, advanced X-Ray inspection equipment is built with compartmentalized internal structures. Sensitive components such as X-Ray generators, detectors, and control boards are housed in separate, insulated zones. This modular separation not only prevents cross-contamination in the event of a breach but also simplifies maintenance and minimizes downtime.

By physically isolating critical components, the design enhances both operational stability and serviceability—key factors in 24/7 production environments.

Preventing System Failure Through Ingress Protection

Moisture-related failure is one of the most common causes of X-Ray inspection system downtime in food factories. Water ingress can lead to short-circuited boards, corroded wiring, blurred X-ray images, or malfunctioning sensors. In a worst-case scenario, contamination can spread to other machinery or product batches, triggering costly recalls and regulatory consequences.

To address these risks, high-quality X-Ray inspection machines are equipped with layered defense systems, such as:

Industrial-grade gaskets made from food-safe, heat-resistant materials to ensure long-term sealing.

Sloped or curved housing surfaces that prevent water from pooling and facilitate rapid drainage after washdowns.

Positive pressure enclosures or air knife systems that prevent moisture from entering through vents or seams.

These features help create a watertight and hygienic shell around the core technologies, allowing food X-Ray inspection systems to operate continuously even in aggressive washdown environments.

Ultimately, robust ingress protection is not just about durability—it’s about preserving detection accuracy, minimizing downtime, and protecting food quality from contamination-related risks. It also sends a message to regulators and customers alike: this facility takes product safety seriously.

Hygienic Design for Food Safety Compliance

In modern food processing facilities, especially those handling liquids, semi-liquids, or products prone to microbial growth, ensuring hygiene is just as critical as the technical capabilities of the X-Ray inspection system. The design of food X-Ray inspection equipment must not only support precise detection of contaminants but also facilitate thorough cleaning and sanitation to prevent bacterial buildup and cross-contamination. This is essential for maintaining rigorous food safety standards, meeting regulatory requirements, and protecting consumer health.

A well-designed hygienic X-Ray inspection machine serves a dual purpose: it guarantees the effectiveness of contaminant detection while minimizing risks associated with microbial contamination. Additionally, hygienic design helps manufacturers avoid costly product recalls, production shutdowns, and reputational damage that result from contamination incidents.

Smooth Surfaces, Sloped Panels, and Easy-to-Clean Structures

One of the core principles in hygienic design for X-Ray inspection systems is the use of smooth, non-porous surfaces. These surfaces resist accumulation of dirt, food residue, and microbial biofilms, making cleaning easier and more effective. Moreover, the integration of sloped panels and rounded corners in the X-Ray inspection equipment design prevents water and cleaning agents from pooling on surfaces. This is vital in food processing environments where standing water can become a breeding ground for bacteria.

Such design features not only expedite washdown procedures but also reduce the chance of cross-contamination by ensuring that all areas of the X-Ray inspection machine are fully accessible for cleaning staff. In wet or humid environments—common in sectors like dairy, seafood, and meat processing—these easy-to-clean structures are crucial for maintaining continuous production without compromising food quality or safety.

Use of Food-Grade Stainless Steel and Anti-Bacterial Coatings

Material selection is fundamental when it comes to hygienic design in food X-Ray inspection systems. Food-grade stainless steel is universally recognized for its excellent corrosion resistance, mechanical strength, and inertness. These properties allow the X-Ray inspection machine to withstand frequent exposure to harsh cleaning agents, high-pressure water jets, and aggressive sanitation protocols without degrading or contaminating the product.

Beyond stainless steel, many advanced X-Ray inspection machines incorporate specialized anti-bacterial coatings or treatments on critical contact surfaces. These coatings actively inhibit microbial growth and biofilm formation, providing an additional layer of defense against contamination. The synergy of durable materials and anti-bacterial surface technologies ensures that the X-Ray inspection equipment supports safer food production environments and aligns with increasingly stringent regulatory standards.

Meeting HACCP and Other Sanitary Design Standards

Compliance with international food safety frameworks such as HACCP (Hazard Analysis and Critical Control Points) is a driving factor behind the hygienic design of modern X-Ray inspection systems. These frameworks emphasize the minimization of contamination risks throughout the food production lifecycle, making equipment design a key control point.

Leading manufacturers of food X-Ray inspection machines rigorously apply sanitary design principles to meet or exceed HACCP guidelines, ISO 22000, and other global food safety certifications. Features such as fully sealed enclosures, CIP (Clean-in-Place) compatibility, and hygienic interfaces ensure that these systems integrate seamlessly into existing production lines while supporting automated and efficient cleaning routines.

By achieving these standards, X-Ray inspection equipment not only guarantees regulatory compliance but also reinforces customer confidence in product safety and brand integrity. This level of commitment to hygiene reflects a proactive approach in safeguarding public health and sustaining competitive advantage in the food industry.

In conclusion, the hygienic design of X-Ray inspection systems is a vital factor in ensuring safe, reliable, and efficient food production—especially in environments prone to moisture and contamination risks. By combining smooth, easy-to-clean structural elements with high-grade materials and strict adherence to sanitary standards, modern food X-Ray inspection machines provide robust protection for both the manufacturing process and consumer well-being. This comprehensive approach enables manufacturers to maintain consistent food quality, meet stringent safety requirements, and uphold the highest levels of operational excellence.

Performance Benefits of Hygienic and Waterproof X-Ray Systems

In food processing industries where wet and harsh environments prevail, choosing hygienic and waterproof X-Ray inspection systems brings significant performance advantages. These benefits not only improve the reliability of food safety inspections but also contribute to operational efficiency and cost savings. By investing in robust X-Ray inspection equipment, manufacturers can ensure continuous, high-quality inspection even under challenging conditions.

Enhanced Durability and Reduced Maintenance Costs

One of the primary benefits of hygienic and waterproof X-Ray inspection machines is their enhanced durability. The integration of waterproof seals, corrosion-resistant materials, and hygienic design features protects sensitive internal components from moisture and contaminants. This reduces wear and tear, significantly extending the service life of the equipment.

As a result, maintenance frequency and repair costs decrease, lowering overall operational expenses. Reliable durability means fewer unexpected breakdowns, which is especially critical in continuous production environments. For food manufacturers, this translates into consistent food X-Ray inspection performance and better return on investment in inspection technology.

Consistent Detection Accuracy Under Extreme Humidity

Humidity and moisture can severely impact the performance of conventional X-Ray inspection systems, leading to image distortion or sensor malfunction. However, waterproof and hygienically designed X-Ray inspection machines maintain consistent detection accuracy even in high-humidity environments such as seafood processing plants or dairy facilities.

By preventing water ingress and reducing condensation inside the system, these advanced X-Ray inspection systems ensure that foreign contaminants are accurately identified without false negatives or positives. This reliability is crucial for protecting consumer safety, maintaining regulatory compliance, and upholding stringent food quality standards.

Minimal Downtime Due to Water Damage or Contamination

Downtime caused by water damage or contamination in inspection equipment can disrupt production schedules and lead to costly delays. Hygienic and waterproof X-Ray inspection equipment is specifically engineered to mitigate these risks. Features such as sealed enclosures, IP66 or IP69K-rated protection, and hygienic surface designs reduce the likelihood of water-related failures.

When combined with easy-to-clean and CIP-compatible designs, these systems enable rapid maintenance and reduce cleaning-related downtime. The result is more efficient production lines with fewer interruptions, helping manufacturers meet high throughput demands while ensuring continuous food X-Ray inspection integrity.

In summary, hygienic and waterproof X-Ray inspection systems deliver significant performance benefits by enhancing durability, maintaining detection accuracy in moist environments, and minimizing downtime. These advantages make them indispensable tools for food processing operations committed to achieving superior food quality and safety.

Choosing the Right X-Ray Inspection System for Wet Conditions

Selecting the appropriate X-Ray inspection system for wet and harsh food processing environments is critical to ensuring reliable operation and maintaining high food safety standards. The right system not only delivers accurate contaminant detection but also withstands challenging conditions such as high humidity, frequent washdowns, and exposure to cleaning chemicals. Careful consideration of design features and customization options will help manufacturers optimize their food X-Ray inspection processes in wet-line applications.

Key Selection Criteria: IP Rating, Component Isolation, Material

When choosing an X-Ray inspection machine for wet conditions, the first factor to evaluate is the system’s ingress protection (IP) rating. An IP66 rating is often the minimum requirement, providing strong defense against dust and powerful water jets, while IP69K offers the highest protection, including resistance to high-pressure and high-temperature washdowns. This ensures the X-Ray inspection equipment can operate reliably in environments subjected to rigorous sanitation protocols.

Component isolation is another important consideration. Systems designed with separated compartments for electrical controls, radiation sources, and detectors prevent water and moisture from affecting critical parts. This isolation enhances both the durability and accuracy of the X-Ray inspection system under wet conditions.

Material choice plays a pivotal role in system longevity. Food-grade stainless steel, known for its corrosion resistance and ease of cleaning, is the industry standard for hygienic X-Ray inspection machines. Non-toxic, anti-bacterial coatings further support food safety by preventing microbial growth on exposed surfaces.

Customization Options for Different Wet-Line Applications

Food production lines vary widely in their wet environment challenges, making customization essential when selecting X-Ray inspection equipment. For example, seafood processing plants may require enhanced corrosion resistance and higher IP ratings due to saltwater exposure, while dairy facilities might prioritize CIP (Clean-in-Place) compatibility for frequent cleaning cycles.

Customization options include adjustable pipe sizes and configurations to fit specific line dimensions, specialized sealing materials to resist aggressive cleaning agents, and modular designs that facilitate maintenance without compromising waterproofing. Some X-Ray inspection systems also offer tailored software settings and AI-powered detection algorithms to adapt to different product viscosities and contaminant types encountered in wet lines.

By selecting a customizable X-Ray inspection machine, manufacturers can ensure optimal performance and compliance regardless of the unique demands posed by their specific wet food processing applications.

In conclusion, choosing the right X-Ray inspection system for wet environments requires a focus on ingress protection, component isolation, durable materials, and application-specific customization. Investing in a purpose-built food X-Ray inspection solution ensures reliable contaminant detection, reduced downtime, and enhanced food safety across diverse wet processing lines.

Future Trends in Hygienic and Waterproof Design

As the food industry continues to evolve, the design of X-Ray inspection systems for wet and hygienic environments is rapidly advancing. Innovations in technology and engineering are enabling more reliable, efficient, and user-friendly food X-Ray inspection solutions. Looking ahead, several key trends are shaping the future of waterproof and hygienic X-Ray inspection equipment, enhancing their performance and ease of use in demanding food processing lines.

Integration of AI for Predictive Maintenance in Wet Settings

Artificial Intelligence (AI) is becoming a game-changer in the operation and maintenance of X-Ray inspection machines, especially in wet and harsh environments. By leveraging AI algorithms, modern systems can monitor operational parameters and detect early signs of wear or potential failure caused by moisture, corrosion, or mechanical stress.

This predictive maintenance capability allows food manufacturers to schedule timely repairs or part replacements before issues lead to downtime. For wet-line applications, where cleaning cycles and water exposure increase equipment stress, AI-driven predictive maintenance enhances the reliability and longevity of X-Ray inspection systems, ultimately safeguarding food quality and reducing operational costs.

Modular Systems for Easier Sanitation and Upgrades

Modularity is another key trend influencing the design of waterproof and hygienic X-Ray inspection equipment. Modular X-Ray inspection machines allow components such as detectors, control units, and rejection mechanisms to be easily accessed, replaced, or upgraded without dismantling the entire system.

This design simplifies sanitation processes by enabling thorough cleaning of individual modules, crucial in wet environments where maintaining hygiene is paramount. Additionally, modularity supports scalability and customization, allowing manufacturers to adapt their food X-Ray inspection systems quickly to new product lines or updated regulatory requirements, maximizing operational flexibility.

Smart Diagnostics for Real-Time Performance Monitoring

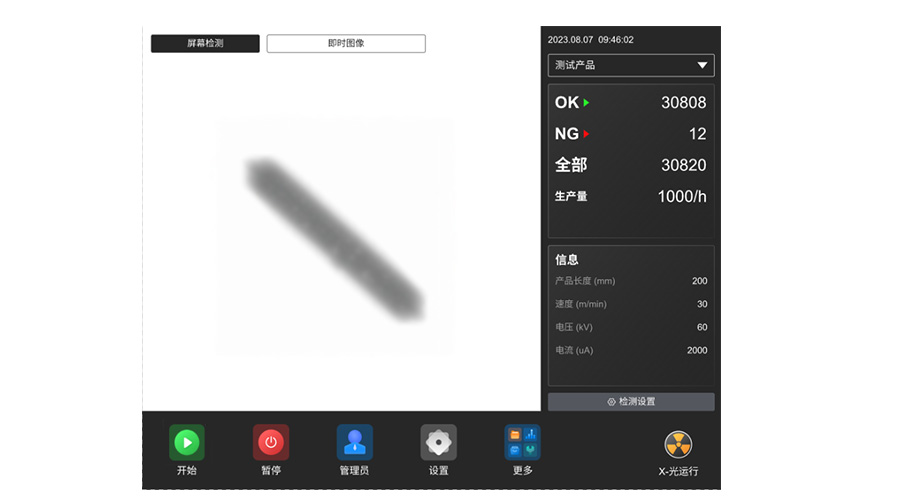

Smart diagnostics integrated into X-Ray inspection systems provide real-time monitoring of machine health and inspection performance. Sensors continuously track factors like temperature, humidity, detector status, and contamination events, feeding data into centralized control platforms.

For wet processing lines, this real-time insight helps operators quickly identify any issues caused by moisture ingress or cleaning cycles, minimizing the risk of undetected contaminants or system failures. Alerts and automated reports generated by these smart diagnostics improve maintenance efficiency and ensure the X-Ray inspection equipment maintains consistent detection accuracy, thereby upholding the highest food safety standards.

In summary, the future of hygienic and waterproof design in X-Ray inspection systems is closely tied to advancements in AI, modular construction, and smart diagnostics. These trends empower food producers to maintain superior food quality and safety even under the toughest wet processing conditions, making food X-Ray inspection machines more reliable, adaptable, and efficient than ever before.

Conclusion

Summary of How Waterproof and Hygienic Designs Boost Food X-Ray Inspection Performance

Waterproof and hygienic design features are critical for optimizing the performance and reliability of X-Ray inspection systems in wet and challenging food processing environments. By incorporating high IP ratings, sealed cabinets, and corrosion-resistant materials, X-Ray inspection machines are protected against water ingress, condensation, and damage from cleaning agents. These design elements ensure consistent operation, minimizing downtime and maintenance costs.

At the same time, hygienic structures with smooth surfaces, sloped panels, and food-grade stainless steel enable thorough cleaning and help prevent bacterial growth, which is vital for maintaining stringent food safety standards. Such designs support continuous, accurate food X-Ray inspection even under frequent washdowns and aggressive sanitation protocols.

Together, these waterproof and hygienic innovations enhance the overall durability, detection accuracy, and uptime of X-Ray inspection equipment, thereby ensuring superior food quality and compliance with industry regulations.

Encouraging Zero-Contamination Goals in Food Quality Control

Achieving zero contamination is the ultimate objective in modern food quality control, and advanced X-Ray inspection systems play an indispensable role in reaching this goal. Waterproof and hygienic design elements not only safeguard the equipment but also strengthen the food safety barrier by enabling reliable detection of foreign objects in harsh environments.

By investing in well-engineered X-Ray inspection machines, food producers can significantly reduce the risk of contamination-related recalls and consumer safety incidents. This commitment to excellence helps build brand trust and supports regulatory compliance across diverse sectors such as dairy, seafood, meat, and beverages.

Looking forward, integrating these design principles with emerging technologies like AI and smart diagnostics will further empower food manufacturers to uphold the highest standards of food quality and safety—paving the way toward truly zero-defect production in the food industry.

FAQ

Q: Why is waterproofing important in food X-Ray inspection machines for wet production lines?

A: Waterproofing prevents moisture ingress that can damage internal components of X-Ray inspection equipment. It ensures system reliability, safety, and hygiene compliance in washdown and high-humidity food production environments.

Q: How does hygienic design enhance food X-Ray inspection performance?

A: Hygienic design minimizes contamination risks by using smooth, corrosion-resistant materials, avoiding bacterial traps, and allowing for easy cleaning, which is crucial for maintaining food quality and safety standards.

Q: What maintenance strategies help extend the lifespan of X-Ray inspection equipment in wet environments?

A: Strategies include regular cleaning with approved detergents, checking seals and gaskets, scheduled component inspections, and using predictive AI diagnostics to detect issues early.