Solutions Across Multiple Industries

Explore our X-Ray inspection systems, metal detectors, and vision inspection systems designed specifically for the meat, seafood, fruit, and vegetable industries. Browse our past projects and case studies to see how our advanced technology enhances your production line.

- Snack

- Meat Poultry

- Beverage

- Bulk

- Seafood

- Fruits & Vegetables

- Cheese & Dairy

Snack

Ensure snack safety and quality with our advanced X-Ray inspection system. Designed for chips, biscuits, nuts, and more, it accurately detects foreign bodies like metal, glass, and stones—even in complex packaging—without compromising product integrity or speed.

- Multi-pack Compatibility

- Small Contaminant Sensitivity

- Aluminum Foil Compatibility

- Advanced Image Analysis

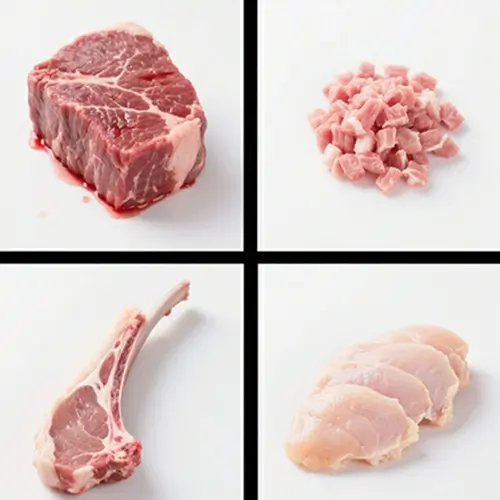

Meat Poultry

Ensure the highest safety standards with our X-Ray inspection system, designed specifically for meat and poultry products. It accurately detects bone fragments, metal pieces, and other foreign contaminants—even in dense or overlapping portions.

- High-resolution Bone Detection

- Real-time Image Processing

- Dual-energy Inspection Technology

- Waterproof Hygienic Design

Beverage

Ensure beverage safety with precision. Our X-Ray inspection system detects contaminants such as glass shards, metal fragments, and dense particles in bottled and canned drinks—without interrupting production flow. Ideal for juice, water, soft drinks, and more.

- Minimal False Positives

- Cap and Seal Check

- Liquid Level Monitoring

- High-speed Bottle Scanning

Bulk

Our X-Ray Inspection System is designed for bulk food and raw materials, detecting foreign bodies like stones, glass, and metal with unmatched precision. Ideal for nuts, grains, powders, and more — it ensures safety before packaging or processing begins.

- AI Self-learning

- Various Rejection Systems Available

- Accurate Foreign Object Removal

- Low False Reject Rate

Seafood

Ensure the highest quality and safety in seafood processing with our advanced X-Ray inspection system. Designed to detect bones, shells, metal fragments, and other foreign contaminants, it delivers precise inspection for various seafood products including fish fillets, shrimp, squid, and more — even through ice or vacuum packaging.

- High-resolution TDI Sensor

- Easy Cleaning Structure

- Real-time Image Display

- Multi-lane Detection Support

Fruits & Vegetables

Our X-Ray inspection system accurately detects foreign objects and internal defects in fruits and vegetables, ensuring high-quality, safe produce. It delivers fast, non-destructive inspection suited for delicate and irregularly shaped items, helping maintain freshness and consumer confidence.

- Internal Defect Identification

- Handle Irregular Shapes

- Easy Operation Interface

- Real-time Image Processing

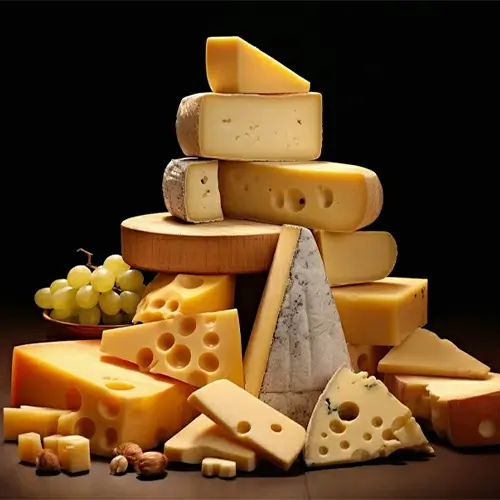

Cheese & Dairy

The X-Ray inspection system for cheese and dairy products offers reliable detection of foreign objects like metal, bone, and plastic contaminants. It ensures product safety and quality without damaging delicate dairy items. With advanced imaging technology, it delivers fast, accurate, and non-destructive inspection for consistent quality control in cheese and dairy production.

- Adapted for Soft Products

- Real-time Defect Detection

- High-speed Inspection

- Hygienic Stainless Steel

Frequently Asked Questions

Everything You Need to Know About Foodman X-Ray Inspection System, Metal Detector and Vision Inpsection System

Product-Specific FAQs Section

No. Food-grade X-Ray systems operate at safe energy levels that do not affect taste, texture, or nutritional quality.

Yes. They generate inspection images and data logs, which can be stored for audits, compliance, and process optimization.

Automatic reject devices, such as air blasts or retractable arms, eject contaminated items from the production line.

Missing labels, misaligned seals, incorrect barcodes, print errors.

Label verification, barcode reading, seal inspection, packaging integrity.

Maintenance and Support FAQs Section

Yes. Most modern X-Ray, metal detection, and vision systems allow remote monitoring, troubleshooting, and updates via secure internet connections.

Key components include the aperture, conveyor belt, reject system, and electronic modules. Routine inspection and cleaning are critical.

Common spare parts include conveyor belts, shielding curtains, sensors, touch screens, and the X-Ray tube. Keeping these in-house minimizes repair delays.

Yes. Although X-Ray inspection machines use low-energy levels safe for operators, radiation leakage checks should be performed at least annually to comply with safety regulations.

Environmental stress can reduce detection accuracy and shorten equipment lifespan. Regular cleaning, installing protective enclosures, and ensuring proper ventilation will help maintain stable operation.