Introduction

Brief Overview of Food Safety Challenges in Modern Food Processing

In today’s fast-paced food industry, ensuring food safety has become more complex than ever. With increasing production volumes, diverse raw materials, and global supply chains, the risk of contamination grows significantly. Traditional detection methods often fall short when it comes to identifying hidden or non-metallic hazards, which makes advanced technologies essential for modern food processing plants.

Why Contaminant Detection Is Critical for Consumer Health and Brand Protection

The presence of contaminants such as metal fragments, glass shards, stones, or bone pieces can pose serious health risks to consumers. Beyond health concerns, even a single contamination incident can damage a brand’s reputation, lead to costly recalls, and reduce consumer trust. This is why implementing a reliable X-Ray inspection system is not just an option—it is a necessity for food processors who aim to maintain high standards of safety and quality.

Introduction to X-Ray Inspection Systems as an Advanced Solution

X-Ray inspection equipment has emerged as a powerful solution for detecting a wide range of contaminants in packaged and bulk food products. Unlike conventional metal detectors, a food X-Ray inspection machine can identify metallic and non-metallic contaminants, including glass, stones, ceramics, bones, and even dense plastics.

Modern X-Ray inspection machines are designed to deliver high precision, speed, and efficiency. They not only enhance food safety but also help manufacturers comply with strict international regulations. With the integration of smart algorithms and real-time data recording, X-Ray inspection systems provide both detection accuracy and full traceability, ensuring long-term protection for both consumers and brands.

By adopting advanced food X-Ray inspection equipment, food processors can effectively safeguard their products, optimize quality control, and move confidently toward intelligent production.

Understanding X-Ray Inspection Technology

What is an X-Ray inspection system?

An X-Ray inspection system is an advanced quality control solution widely used in the food industry to identify contaminants and defects within products. Unlike conventional detection methods, food X-Ray inspection uses high-energy X-rays to scan products and create detailed images based on density variations. This process provides not only superior accuracy but also the ability to inspect through multiple types of packaging, including foil, metalized film, and glass containers, which are often challenging for traditional detection technologies.

This ability makes X-Ray inspection equipment a vital investment for food manufacturers who need to comply with international food safety standards such as HACCP, BRC, and IFS. By integrating an X-Ray inspection machine into production lines, companies can safeguard consumer health, avoid costly recalls, and strengthen their brand reputation in increasingly regulated global markets. As a result, these systems have become a core tool for modern food safety and quality assurance.

How X-Ray Inspection Machines Detect Contaminants?

An X-Ray inspection machine works on the principle of density-based detection. When X-rays pass through food products, the system captures grayscale images where denser materials—such as metal, glass, stone, or bone—appear differently compared to the surrounding food. Advanced image processing algorithms then analyze these density variations to identify foreign objects, regardless of their shape or position within the product.

Unlike other inspection methods, food X-Ray inspection systems are not affected by product temperature, moisture, or salt content. This makes them highly reliable across a wide range of applications, from frozen seafood and meat to baked goods, dairy, and packaged snacks. Additionally, the latest X-Ray inspection equipment can detect even the smallest contaminants, with precision levels as fine as 0.2 mm depending on the system configuration.

Beyond contaminant detection, these machines can also check for broken products, missing pieces, or inconsistencies in shape and size. This multifunctional capability ensures consumer safety while improving production efficiency and reducing waste.

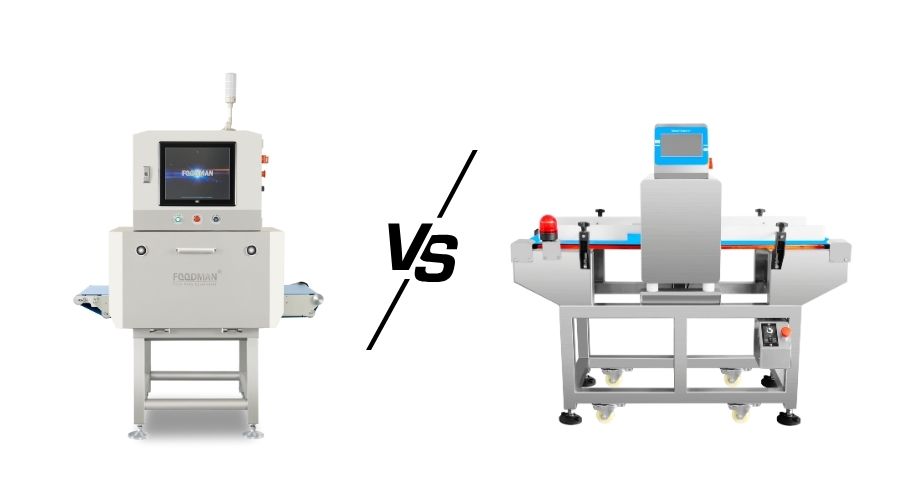

Key Differences Between X-Ray Inspection Equipment and Traditional Metal Detectors

While metal detectors remain common in food processing, they are limited to identifying metallic contaminants only, and their accuracy may be reduced when products are packaged in aluminum foil or other metallic packaging. In contrast, X-Ray inspection equipment can detect both metallic and non-metallic contaminants, such as glass, ceramics, stones, and dense plastics. This broader detection capability makes them far more versatile for today’s diverse food products.

Furthermore, an X-Ray inspection system can perform advanced quality control checks beyond contaminant detection. These include verifying product mass, detecting underfilled or overfilled packages, counting components in multipacks, identifying missing or broken items, and ensuring packaging integrity. For instance, a food X-Ray inspection machine can simultaneously verify that a candy bar has the correct number of pieces while also checking for contaminants.

This all-in-one functionality reduces the need for multiple inspection devices, saves factory floor space, and streamlines production. As a result, the X-Ray inspection machine provides not only higher safety standards but also improved operational efficiency.

By understanding these differences, food manufacturers can better appreciate why food X-Ray inspection is not just an optional tool but an essential investment for ensuring both safety and brand protection in today’s competitive and highly regulated market.

Safety Concerns About X-Ray Inspection

Common Misconceptions About Radiation Exposure in Food X-Ray Inspection

One of the biggest concerns surrounding food X-Ray inspection is the fear of radiation exposure. Many consumers mistakenly believe that food processed through an X-Ray inspection machine becomes radioactive or unsafe to eat. This misconception often stems from confusion with nuclear radiation or medical X-rays.

In reality, the radiation levels used in an X-Ray inspection system are extremely low, controlled, and carefully regulated. The process is similar to taking a photograph: X-rays pass through the product briefly, creating an image, but do not leave any residual radiation. Food that has been inspected using X-Ray inspection equipment is 100% safe for consumption, with no impact on taste, texture, or nutritional value.

Clarifying How X-Ray Inspection Systems Are Designed for Food Safety Compliance

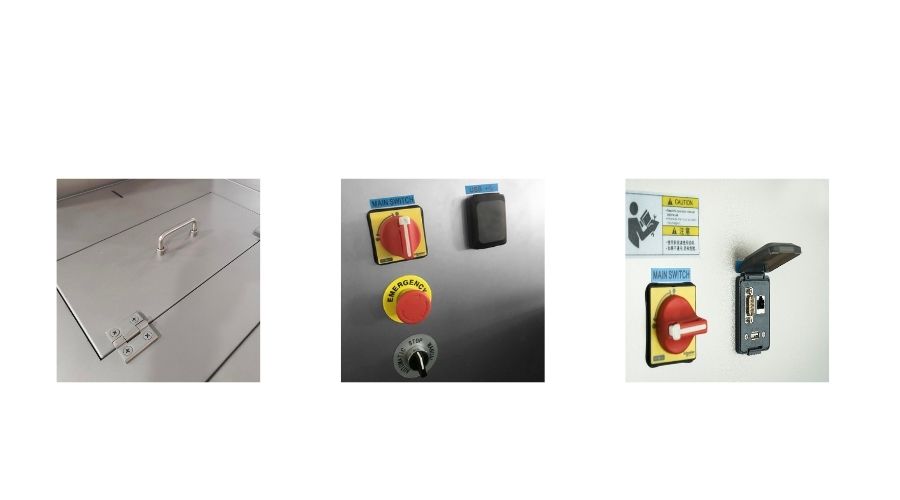

X-Ray inspection systems are specifically engineered to ensure food safety compliance. These machines are equipped with advanced shielding and safety interlocks that prevent any radiation leakage into the working environment. Operators and workers are fully protected during the inspection process, making X-Ray inspection machines safe for continuous use in food production lines.

Additionally, modern food X-Ray inspection equipment operates within strict safety parameters, often producing lower radiation doses than a typical airport security scanner. This ensures both the food and the people working around the system remain safe. Manufacturers design every X-Ray inspection system to comply with global food safety standards, ensuring the technology not only improves contaminant detection but also upholds health and safety requirements.

International Safety Regulations and Certifications That Govern X-Ray Inspection Equipment

To further eliminate safety concerns, X-Ray inspection equipment is regulated by internationally recognized safety standards and certifications. For example, organizations such as the FDA (Food and Drug Administration), CFIA (Canadian Food Inspection Agency), and EFSA (European Food Safety Authority) provide clear guidelines on radiation limits and safe operation.

Additionally, X-Ray inspection systems are designed to meet compliance with standards like HACCP (Hazard Analysis Critical Control Point), BRC (British Retail Consortium), and IFS (International Featured Standards). Certification bodies verify that each X-Ray inspection machine operates safely within these limits before being installed in food processing plants.

By adhering to these international regulations, food X-Ray inspection not only ensures maximum contaminant detection but also guarantees that both consumers and workers remain protected. This combination of safety and performance is why leading food manufacturers worldwide trust X-Ray inspection systems as a reliable solution for modern quality control.

Is Food Exposed to Harmful Radiation?

Explanation of Extremely Low Radiation Levels Used in X-Ray Inspection Machines

A common question surrounding food X-Ray inspection is whether radiation levels pose a health risk. The reality is that an X-Ray inspection machine uses extremely low energy levels, just enough to generate a detailed image of the product’s internal structure. These radiation doses are significantly lower than those encountered during medical imaging procedures and are carefully controlled to remain within safe limits.

Modern X-Ray inspection systems are designed with advanced shielding and precise calibration, ensuring that radiation exposure is minimal and well below international safety thresholds. This makes the technology not only effective for contaminant detection but also entirely safe for everyday food processing operations.

How Food Is Not Altered or Made Radioactive During Inspection

Another misconception is that food inspected by X-Ray inspection equipment becomes radioactive or chemically altered. This is scientifically incorrect. During the inspection process, the X-rays pass through the product momentarily, creating a density-based image without leaving behind any residual radiation.

In practice, food X-Ray inspection systems are comparable to airport baggage scanners—quick, safe, and non-invasive. The physical properties, taste, texture, and nutritional value of the food remain unchanged after passing through an X-Ray inspection machine. Consumers can be assured that the inspected food is entirely safe for consumption.

Supporting Scientific Evidence and Industry Research

Extensive scientific studies and industry research confirm that food X-Ray inspection is completely safe. Organizations such as the World Health Organization (WHO), the U.S. Food and Drug Administration (FDA), and the European Food Safety Authority (EFSA) have all reviewed and approved the use of X-Ray inspection systems in food production.

Industry research has consistently shown that the low radiation levels used by X-Ray inspection equipment do not alter food in any way. Moreover, global food safety standards like HACCP, BRC, and IFS recognize X-Ray inspection machines as compliant tools for quality assurance.

These findings provide solid evidence that X-Ray inspection systems are both safe and effective, allowing manufacturers to detect contaminants while guaranteeing that inspected food remains healthy, nutritious, and completely safe for consumers.

Benefits of X-Ray Inspection Beyond Safety

High Accuracy in Detecting Metals, Glass, Stones, Bones, And Plastics

One of the greatest advantages of a modern X-Ray inspection system is its high accuracy in identifying contaminants that go beyond just metal. Unlike traditional metal detectors, an X-Ray inspection machine can detect a wide range of foreign objects such as glass, stones, bones, ceramics, and dense plastics. This makes food X-Ray inspection a far more versatile and reliable solution for safeguarding food quality.

Whether the product is bulk, packaged, or irregularly shaped, X-Ray inspection equipment provides precise detection with minimal false rejects, ensuring both safety and production efficiency.

Non-destructive Detecting—maintaining Food Quality and Integrity

Another key benefit of food X-Ray inspection is that it is completely non-destructive. During inspection, an X-Ray inspection machine scans products without causing any physical damage or alteration. The food remains intact, preserving its taste, texture, and nutritional value.

This makes X-Ray inspection systems ideal for industries where maintaining product quality is as important as detecting contaminants. By enabling non-invasive checks, X-Ray inspection equipment helps manufacturers achieve strict safety standards without compromising product integrity.

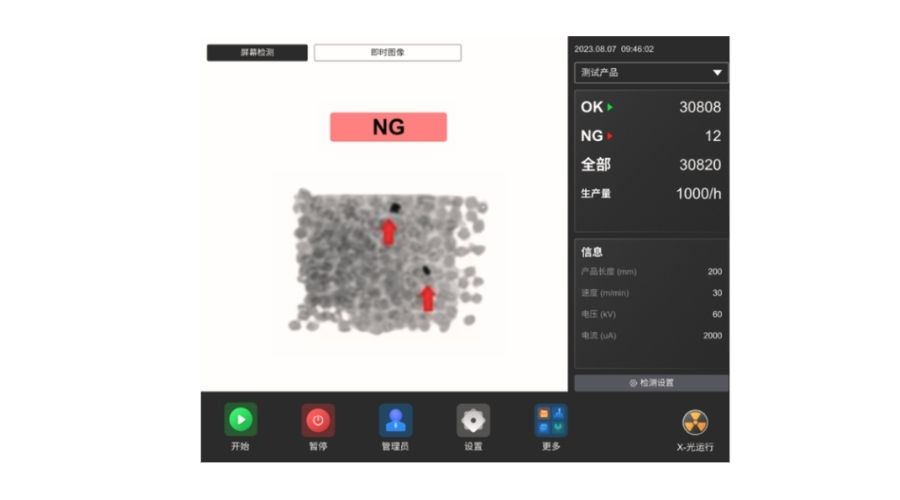

Enhancing Traceability with Image Records and Data Storage

In today’s competitive food industry, traceability is essential for building trust and ensuring compliance. Advanced X-Ray inspection systems are equipped with image recording and data storage features, allowing manufacturers to maintain detailed inspection records.

Every product that passes through an X-Ray inspection machine generates an image that can be stored and reviewed for auditing or quality assurance purposes. This not only supports regulatory compliance but also provides manufacturers with valuable insights for continuous improvement.

By combining contaminant detection with data traceability, food X-Ray inspection plays a vital role in brand protection and consumer confidence.

Regulatory Compliance and Industry Standards

Food Safety Standards (e.g., FDA, EU, HACCP, BRC, ISO) That Approve X-Ray Inspection Equipment

Food safety is heavily regulated worldwide, and compliance is a non-negotiable requirement for manufacturers. X-Ray inspection equipment is widely recognized and approved under global standards such as FDA (U.S. Food and Drug Administration), EU food directives, HACCP (Hazard Analysis and Critical Control Points), BRC (British Retail Consortium), and ISO certifications. These organizations confirm that X-Ray inspection systems are safe, effective, and suitable for use in food processing environments.

By adhering to these standards, manufacturers using food X-Ray inspection demonstrate their commitment to consumer safety and quality assurance. This not only reduces regulatory risks but also strengthens brand reputation in competitive markets.

Why Global Food Exporters Rely on Food X-Ray Inspection to Meet Compliance Requirements

For global food exporters, compliance with international safety standards is essential to access key markets. Traditional methods such as metal detection often fall short, especially when detecting non-metallic contaminants. That’s why exporters increasingly invest in X-Ray inspection machines—to guarantee their products meet the strict requirements of importing countries.

An advanced X-Ray inspection system ensures that products are free from contaminants like glass, stones, bones, and dense plastics, giving exporters the confidence to pass inspections across multiple regulatory environments. As a result, food X-Ray inspection has become a critical part of global supply chains, ensuring that products can move across borders without delays or compliance issues.

Case Examples of Industries Successfully Using X-Ray Inspection Systems

Many industries have already integrated X-Ray inspection equipment into their production lines with measurable success. For example:

Meat and poultry processors use X-Ray inspection machines to detect bones and other hard contaminants, ensuring consumer safety and regulatory approval.

Dairy producers rely on X-Ray inspection systems to check for contaminants in cheese blocks and packaged milk products, maintaining compliance with HACCP and BRC.

Snack and confectionery manufacturers employ food X-Ray inspection to identify small fragments of glass or metal in packaged goods, protecting both consumers and brand reputation.

These real-world applications demonstrate how X-Ray inspection not only meets compliance standards but also adds value to production efficiency and quality assurance.

Practical Considerations for Manufacturers

Where to Install X-Ray Inspection Machines in Processing Lines

When integrating an X-Ray inspection machine into a food production line, strategic placement is essential. Most manufacturers install X-Ray inspection systems at critical control points—such as after packaging, before distribution, or directly after mixing raw materials. For bulk products, food X-Ray inspection may be most effective earlier in the process, while for packaged goods, X-Ray inspection equipment is usually placed at the end of the line to ensure final product safety. Correct placement maximizes detection accuracy and minimizes the risk of contaminated products reaching consumers.

Training and Maintenance for Safe, Efficient Operation

To fully benefit from X-Ray inspection systems, manufacturers must invest in operator training and routine maintenance. Staff should be trained to interpret images, adjust sensitivity levels, and respond quickly when contaminants are detected. Preventive maintenance on X-Ray inspection machines—such as calibration checks, software updates, and part replacements—ensures long-term efficiency and compliance. Regular training also helps operators stay updated on safety protocols, making food X-Ray inspection both reliable and user-friendly. Well-maintained X-Ray inspection equipment reduces downtime, prevents costly recalls, and enhances overall production efficiency.

Cost-Benefit Analysis: Balancing Safety, Efficiency, And ROI

Although investing in an X-Ray inspection system requires upfront costs, the long-term benefits far outweigh the initial expense. By preventing recalls, avoiding fines, and protecting brand reputation, food X-Ray inspection directly contributes to higher profitability. In addition, X-Ray inspection equipment often performs multiple functions—such as contaminant detection, weight verification, and package integrity checks—reducing the need for additional machines. This multifunctionality improves efficiency and lowers operating costs. Ultimately, the ROI of an X-Ray inspection machine lies in its ability to ensure safety, maintain compliance, and boost consumer trust—all while supporting a streamlined, cost-effective production line.

Conclusion

Reinforcing the Safety of X-Ray Inspection for Food Processing

X-Ray inspection has proven to be a safe, effective, and non-destructive method for detecting contaminants in food. Modern X-Ray inspection systems are designed with strict radiation shielding and compliance standards, ensuring that both operators and products remain completely safe. The use of food X-Ray inspection allows manufacturers to identify foreign objects such as metals, glass, stones, bones, and dense plastics without altering the food’s quality or integrity. With proper installation and operation, X-Ray inspection equipment integrates seamlessly into production lines while maintaining safety and efficiency.

Encouragement for Food Manufacturers to Adopt Advanced X-Ray Inspection Systems

Investing in an X-Ray inspection machine is no longer optional for forward-thinking food manufacturers. By adopting advanced X-Ray inspection systems, producers can enhance product quality, minimize risks of contamination, and protect brand reputation. Food X-Ray inspection provides detailed imaging and real-time detection, helping manufacturers maintain strict control over production and consistently meet regulatory requirements. The versatility of X-Ray inspection equipment also allows for the detection of a wide range of contaminants, making it an indispensable tool for modern food processing operations.

Final Call-to-Action: Ensuring Consumer Trust Through Safe, Efficient, And Reliable Contaminant Detection

Ultimately, the adoption of X-Ray inspection represents a commitment to consumer safety and trust. By utilizing cutting-edge X-Ray inspection machines and food X-Ray inspection equipment, manufacturers can ensure reliable contaminant detection, maintain compliance with international standards, and streamline their production processes. Safe, efficient, and accurate X-Ray inspection systems not only prevent costly recalls but also reinforce a brand’s reputation for quality. Food producers are encouraged to integrate X-Ray inspection into their operations to deliver products that consumers can trust, every time.

FAQ

Q: Is food exposed to harmful radiation during X-Ray inspection?

A: No. The radiation levels are extremely low, safe, and do not make food radioactive or alter its quality.

Q: Are X-Ray inspection machines compliant with international food safety standards?

A: Yes. They comply with FDA, HACCP, BRC, IFS, and other global food safety regulations.

Q: What is the ROI of investing in X-Ray inspection equipment?

A: By preventing recalls, ensuring compliance, and protecting brand reputation, X-Ray inspection offers long-term cost savings and higher efficiency.