Introduction

Briefly Introduce What Real-Time Imaging Means in the Context of X-Ray Inspection

Real-time imaging in the context of X-Ray inspection refers to the immediate capture and processing of internal product images as they move along a production line. Unlike traditional batch-based analysis, real-time imaging allows X-Ray inspection systems to identify foreign objects, defects, or inconsistencies on the spot. This capability is enabled by high-speed sensors and advanced software, making modern X-Ray inspection machines far more efficient and responsive than their predecessors.

Highlight the Growing Demand for Instant and Accurate Quality Control in Industries Such as Food, Pharmaceuticals, And Logistics

Industries such as food, pharmaceuticals, and logistics operate in fast-paced environments where quality issues must be detected and resolved immediately. This has led to a sharp rise in demand for instant and accurate quality control solutions. Manufacturers are increasingly investing in high-performance X-Ray inspection equipment that can deliver real-time insights to prevent contaminated or defective products from reaching consumers. Whether scanning food trays for metal fragments or checking pharmaceutical blisters for missing pills, X-Ray inspection systems with real-time imaging have become essential for compliance, safety, and consumer trust.

Preview How Real-Time Imaging Enhances Detection Performance and Operational Efficiency

The integration of real-time imaging into food X-Ray inspection and other industrial applications has significantly enhanced detection capabilities. By analyzing products in motion, X-Ray inspection systems can automatically reject faulty items without slowing down production. This not only minimizes human error and waste but also ensures continuous quality control. Real-time imaging enables manufacturers to respond quickly to issues, reduce downtime, and streamline operations—making it a cornerstone of modern quality assurance strategies.

Understanding Real-Time Imaging Technology

Explain How Real-Time Imaging Works: Continuous Data Acquisition and Image Processing During Product Flow

Real-time imaging in X-Ray inspection refers to the continuous acquisition and analysis of images as products move along the production line. Unlike traditional stop-and-scan methods, a modern X-Ray inspection system uses dynamic scanning technology that allows for on-the-fly detection of contaminants or quality issues. As each product passes through the X-Ray inspection machine, the system captures and processes the image data immediately—eliminating lag time and enabling instant rejection of defective items. This real-time capability is especially crucial in high-speed manufacturing environments, where even a short delay can lead to quality compromise.

Key Components: High-Speed X-Ray Detectors, Imaging Software, And Processing Units

The core of a real-time X-Ray inspection system lies in its advanced components. High-speed X-ray detectors ensure that detailed images are captured without motion blur. These detectors work in tandem with powerful imaging software that interprets the image data, identifying foreign objects or structural inconsistencies with exceptional accuracy. The processing unit, typically embedded within the X-Ray inspection equipment, handles the data with minimal latency to ensure decisions are made in milliseconds. This architecture ensures that food X-Ray inspection is both rapid and reliable—without slowing down production.

Comparison with Traditional Batch or Delayed Inspection Methods

Traditional inspection methods, such as manual checks or post-production sampling, are not only time-consuming but also prone to human error. Even older-generation X-Ray inspection machines that process images in batches or with delay can miss defects or introduce bottlenecks. In contrast, real-time imaging provides continuous monitoring, which means every item is inspected thoroughly and consistently. This shift to real-time food X-Ray inspection dramatically enhances efficiency, product safety, and overall operational agility.

Advantages of Real-Time Imaging in X-Ray Inspection Systems

Real-time imaging has become a transformative capability in modern X-Ray inspection systems, delivering unprecedented accuracy, speed, and traceability in quality control. Whether in food processing, pharmaceuticals, or packaging, the integration of real-time imaging into X-Ray inspection equipment elevates performance and operational reliability.

Immediate Detection and Rejection

One of the most significant advantages of real-time imaging in an X-Ray inspection machine is its ability to instantly identify and reject products contaminated with foreign bodies or exhibiting structural defects. By analyzing each product in motion and triggering immediate removal, X-Ray inspection systems reduce downtime and prevent defective goods from progressing further down the line. This immediate response mechanism not only boosts efficiency but also significantly cuts down on production waste.

Enhanced Sensitivity and Accuracy

Modern X-Ray inspection equipment equipped with real-time imaging offers higher sensitivity than traditional methods. These systems can detect low-density contaminants—such as bones, plastic fragments, or rubber—that would typically be missed by metal detectors. The advanced software algorithms powering today’s food X-Ray inspection solutions ensure that false positives and negatives are minimized, thereby improving both detection reliability and operational consistency.

Comprehensive Quality Control

Beyond contaminant detection, real-time imaging enhances the broader quality control process. A high-performance X-Ray inspection system can simultaneously inspect product shape, structural integrity, fill levels, and even packaging completeness. This inline capability allows manufacturers to enforce strict quality standards without slowing production. Moreover, every scan is digitally recorded, supporting traceability and regulatory compliance—an essential feature for food, pharmaceutical, and other high-risk industries.

Application Scenarios Across Industries

With the advancement of X-Ray inspection technology, real-time imaging is no longer limited to a single application. Modern X-Ray inspection systems are now central to quality control across multiple industries. Whether it’s preventing contaminated food from reaching consumers or ensuring the structural integrity of pharmaceutical products, real-time X-Ray inspection equipment delivers unmatched speed, accuracy, and reliability.

Food Industry

In the food processing sector, maintaining product safety is a top priority. Food X-Ray inspection has become a critical tool in achieving this goal. By leveraging real-time imaging capabilities, X-Ray inspection systems can detect a wide variety of contaminants—including bones in fish or poultry, metal shavings from machinery, pieces of glass from broken containers, and fragments of hard plastic.

These systems can scan products whether they are fresh, frozen, vacuum-sealed, or packaged in foil, overcoming limitations faced by traditional detection technologies such as metal detectors. Thanks to intelligent algorithms, modern X-Ray inspection machines not only detect foreign bodies but also check for product shape abnormalities, underfilled packaging, or missing items in multi-component products like ready meals. The result is improved consumer safety, reduced product recalls, and stronger compliance with food safety standards like HACCP and BRCGS.

Pharmaceutical Industry

In the pharmaceutical industry, accuracy and precision are non-negotiable. X-Ray inspection equipment is widely used to inspect tablets, capsules, powders, vials, blister packs, and medical devices. The real-time imaging function of these X-Ray inspection machines ensures that every unit is checked for integrity, content, and proper packaging—down to the smallest detail.

Whether verifying the presence of all tablets in a blister pack or checking for cracks in glass ampoules, X-Ray inspection systems provide non-invasive, high-resolution screening. This is especially important for high-speed production lines, where manual inspection is impractical. Pharmaceutical companies benefit from increased quality assurance, lower risk of costly recalls, and full traceability of inspection data for regulatory audits.

Logistics & General Manufacturing

In logistics, electronics, and general manufacturing, X-Ray inspection systems play a growing role in quality control and verification. Real-time imaging makes it possible to inspect sealed cartons, aluminum cans, plastic containers, or even wrapped pallets—without unpacking. This saves significant time and labor while reducing the chance of human error.

X-Ray inspection machines in these industries are used to detect missing components in assembled kits, confirm product count, identify packaging defects, and locate foreign objects such as screws, wires, or unwanted materials introduced during packing. Some advanced X-Ray inspection equipment even integrates with ERP or MES systems for automatic rejection and reporting, helping streamline supply chain traceability and improving operational transparency.

Integration with AI and Smart Systems

Modern X-Ray inspection systems are no longer just about hardware—they’re becoming increasingly intelligent through the integration of artificial intelligence (AI), cloud technology, and data-driven automation. These enhancements are transforming traditional X-Ray inspection equipment into smart solutions capable of learning, adapting, and improving over time.

How Artificial Intelligence Enhances Real-Time Decision-Making

AI plays a pivotal role in elevating X-Ray inspection capabilities. By analyzing massive amounts of imaging data in real time, AI algorithms can distinguish between acceptable product variations and actual defects with remarkable speed and accuracy. This allows X-Ray inspection machines to make immediate decisions on whether to reject or accept a product, significantly reducing false positives and minimizing unnecessary waste.

Moreover, AI-driven X-Ray inspection systems can be trained on product-specific datasets, enabling them to better understand context—such as distinguishing between a bone in a chicken thigh (expected) versus a piece of metal (unacceptable). This level of decision-making was previously unattainable in traditional systems without AI support.

Examples of AI-Driven Defect Classification and Adaptive Inspection

AI allows X-Ray inspection equipment to go beyond simple foreign body detection. For example, smart X-Ray inspection machines can now classify defects by type—such as identifying whether a detected object is metal, glass, stone, or plastic—and assign a severity level or corrective action.

In adaptive inspection, the AI adjusts scanning parameters based on product density, size, or packaging material. This means the X-Ray inspection system optimizes performance for each item passing through the line, leading to greater sensitivity and fewer missed defects. In high-mix production environments, this adaptability is a major competitive advantage.

Benefits of Cloud Connectivity and Remote Monitoring

Many next-generation X-Ray inspection systems offer cloud connectivity, enabling real-time remote monitoring and diagnostics. This functionality allows quality managers and technicians to view inspection data, adjust settings, and receive alerts—no matter where they are located.

Through cloud-based dashboards and analytics, manufacturers can identify trends, compare performance across lines or facilities, and ensure compliance with food safety standards. This not only reduces downtime but also supports predictive maintenance, ensuring X-Ray inspection machines remain in optimal working condition.

By combining intelligent software with robust X-Ray inspection equipment, manufacturers gain a scalable, future-proof solution that aligns with Industry 4.0 and smart factory initiatives.

Key Features to Look for in Real-Time X-Ray Inspection Machines

As industries such as food, pharmaceuticals, and logistics move toward smarter, faster, and more precise quality control solutions, selecting the right X-Ray inspection machine becomes increasingly important. Modern X-Ray inspection systems equipped with real-time imaging capabilities offer numerous advanced features that enhance operational efficiency and ensure product safety. Below are the key features manufacturers should look for when choosing an intelligent X-Ray inspection system:

High-Speed Image Acquisition and Processing

The foundation of any effective X-Ray inspection system is its ability to capture and process images in real time. High-speed image acquisition enables X-Ray inspection equipment to scan products as they move along the production line without delay or interruption. Advanced processors and imaging software analyze these images instantly, allowing for immediate identification of foreign materials or defects. This is especially crucial in high-throughput environments where speed cannot come at the expense of accuracy.

Multi-Angle or Dual-Energy Imaging for Complex Products

For irregularly shaped or dense products, such as frozen meals, meat cuts, or pharmaceutical kits, basic imaging may not be sufficient. Leading X-Ray inspection machines are now equipped with multi-angle or dual-energy imaging technologies. These innovations improve depth perception and material differentiation, making it easier to detect contaminants like bones, glass, or metal in challenging conditions. Incorporating such imaging capabilities greatly expands the detection range and versatility of X-Ray inspection equipment.

Real-Time Alert and Rejection System

An essential component of a robust X-Ray inspection machine is a real-time alert and rejection system. This feature ensures that any contaminated or defective item is immediately flagged and automatically removed from the production line. Integration with conveyor belts, diverters, or air nozzles ensures swift and precise rejection, reducing the risk of contamination reaching the end consumer. Real-time alerts also provide operational visibility, helping staff take prompt action when abnormalities occur.

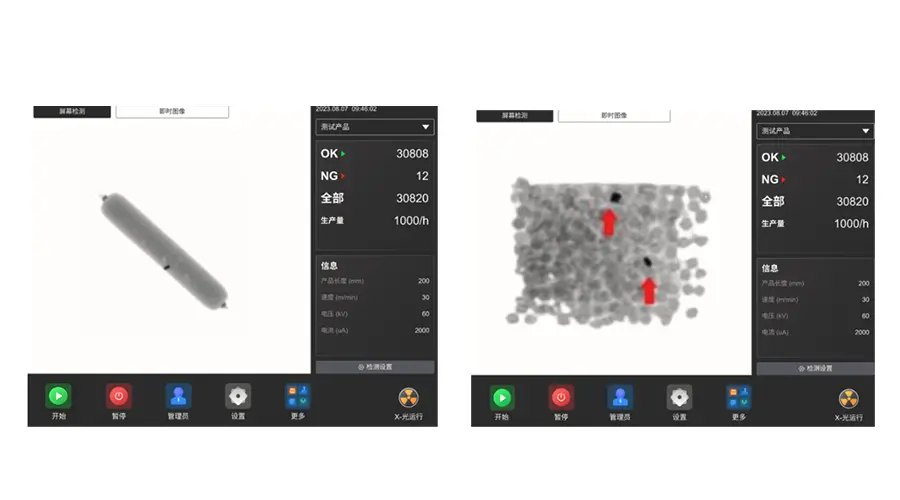

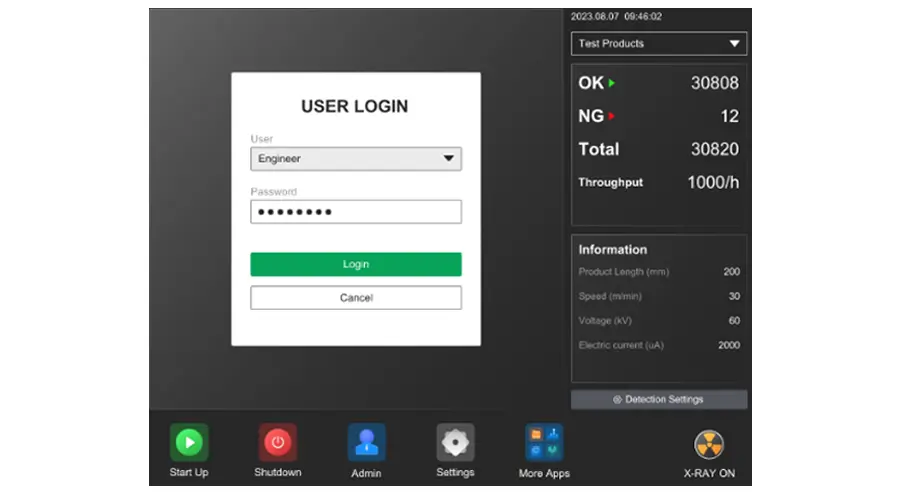

Intuitive User Interface with Visual Feedback

No matter how advanced the hardware, the usability of the X-Ray inspection system plays a critical role in day-to-day performance. A user-friendly interface with visual feedback empowers operators to monitor inspection results in real time, adjust settings easily, and interpret data without extensive training. Many X-Ray inspection systems now include touchscreen controls, clear imaging displays, and diagnostic tools that simplify operations and improve workflow efficiency.

Challenges and Considerations

While real-time imaging brings significant benefits to X-Ray inspection systems, it also introduces a set of challenges that manufacturers and operators must address to ensure consistent performance and return on investment. As the demand for smarter, faster, and more reliable X-Ray inspection equipment grows, so does the importance of planning for the following considerations:

Data Volume and Storage Management

Real-time X-Ray inspection machines generate a substantial volume of high-resolution images and operational data. Managing this data effectively is critical for traceability, compliance, and performance analytics. Manufacturers must ensure that the X-Ray inspection system includes robust data compression, secure storage options, and seamless integration with plant-wide data management systems. Additionally, the ability to retrieve and analyze historical inspection data is crucial for quality audits and process optimization.

Calibration and Maintenance for High-Throughput Systems

To maintain accuracy and reliability, X-Ray inspection machines operating at high speeds must be regularly calibrated. Components such as detectors, light sources, and conveyors require routine checks and preventive maintenance to avoid performance drift or mechanical failure. Selecting an X-Ray inspection system with built-in self-diagnostics, maintenance alerts, and easy-access components can reduce downtime and service costs significantly. Furthermore, using industry-certified X-Ray inspection equipment ensures long-term durability even under continuous, high-volume usage.

Operator Training for Real-Time Response

Even with the most advanced X-Ray inspection equipment, human expertise remains vital. Real-time systems demand that operators respond quickly to alerts and anomalies. Comprehensive training is essential to ensure staff understand how to interpret real-time imaging results, adjust parameters as needed, and initiate appropriate responses to faults or contaminants. Many modern X-Ray inspection systems now offer intuitive user interfaces and visual aids to assist with this, but continuous learning and support should remain a top priority.

Future Outlook

As industries continue to evolve toward greater automation, safety, and precision, the future of X-Ray inspection technology is poised for remarkable innovation. X-Ray inspection systems are no longer just tools for foreign body detection—they are becoming intelligent platforms that support end-to-end quality assurance, predictive maintenance, and smart manufacturing.

Trends in Deep Learning for Smarter Real-Time Inspection

One of the most exciting trends shaping the next generation of X-Ray inspection machines is the integration of deep learning and AI. These technologies enable systems to learn from massive datasets, improve detection accuracy over time, and adapt to different product types without manual reprogramming. With smarter algorithms, food X-Ray inspection systems can now distinguish between harmless variations (like air bubbles) and true contaminants, reducing false positives and improving line efficiency.

3D Imaging and Predictive Analytics

Future-ready X-Ray inspection equipment is also moving toward 3D imaging capabilities, allowing for more detailed internal analysis of complex or irregularly shaped products. This is particularly valuable in industries like pharmaceuticals and prepared foods. Combined with predictive analytics, 3D-enabled X-Ray inspection systems can forecast potential faults or contamination risks before they occur, further enhancing operational reliability.

Modular and Compact Systems for Diversified Production Lines

With increasing demand for flexible production, manufacturers are seeking X-Ray inspection machines that are modular, scalable, and easy to integrate into various environments. Compact X-Ray inspection equipment allows small- to mid-sized facilities to deploy advanced detection without the need for large infrastructure investments. This shift is making food safety and quality control more accessible across the supply chain, especially for SMEs and export-oriented businesses.

In conclusion, the future of X-Ray inspection systems lies in smarter software, more versatile hardware, and deeper integration into the digital ecosystem of modern factories. Investing in forward-thinking technology today will give manufacturers a competitive edge in safety, efficiency, and customer trust tomorrow.

Conclusion

Real-time imaging has transformed the landscape of X-Ray inspection, turning traditional quality control into an intelligent, responsive process. By enabling instant analysis and decision-making, real-time imaging significantly enhances the performance of modern X-Ray inspection systems, allowing manufacturers to detect and reject contaminated or defective products with unmatched precision and speed.

In industries like food processing, pharmaceuticals, and logistics, where safety and quality are non-negotiable, X-Ray inspection equipment with real-time capabilities plays a crucial role. It ensures compliance with strict international standards, protects brand reputation, and safeguards consumer health—all while improving overall line efficiency.

The benefits are clear: enhanced detection accuracy, reduced false rejections, seamless integration with automation systems, and comprehensive traceability. For any business looking to future-proof its operations, investing in an advanced X-Ray inspection machine that supports real-time imaging isn’t just a technical upgrade—it’s a strategic move toward smarter manufacturing.

As production demands grow and regulatory pressures tighten, real-time X-Ray inspection systems will continue to lead the way in modern quality assurance. Now is the time to adopt intelligent detection technologies that elevate performance, reduce risk, and deliver lasting value.

FAQ

Q: What is real-time imaging in X-Ray inspection?

A: Real-time imaging refers to the continuous capture and immediate processing of X-Ray images as products move along a production line. Unlike batch inspection, it enables instant detection and rejection of contaminated or defective items without halting production.

Q: What are the main benefits of using real-time X-Ray inspection systems?

A: Key benefits include immediate foreign body detection, reduced false positives, minimized waste, enhanced operational efficiency, and full traceability for compliance with regulations like HACCP and BRCGS.

Q: How does artificial intelligence enhance real-time X-Ray inspection?

A: AI improves detection accuracy by learning from large datasets, distinguishing between harmless and harmful anomalies, classifying defect types, and adapting scanning parameters based on the product’s characteristics.