Metal Detectors vs. X-ray Systems: Strategies for Enhanced Food Safety

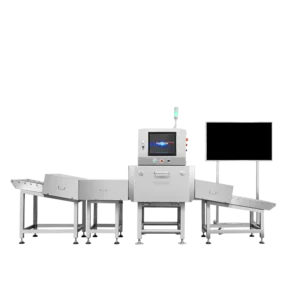

Introduction Ensuring Food Quality and Safety Through Inspection Food safety is no longer a hidden concern but a global priority directly impacting public health, brand reputation, and regulatory compliance. With increasingly complex food supply chains and growing production volumes, manufacturers must adopt advanced inspection technologies to prevent contamination and ensure product integrity. Among the many