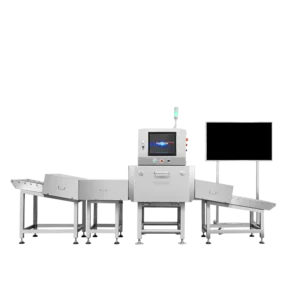

X-Ray Inspection for Eco-Friendly Packaging

Introduction Overview of Eco-Friendly Packaging Trends and Materials In recent years, the food, beverage, and consumer goods industries have increasingly shifted towards eco-friendly packaging to reduce environmental impact and promote sustainability. Materials such as recycled plastics, rPET bottles, biodegradable films, and compostable laminates are becoming standard choices for manufacturers aiming to meet the growing demand