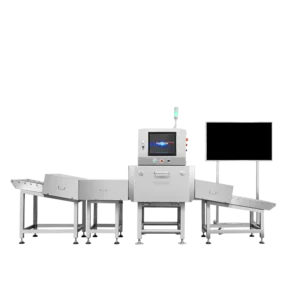

Dual Energy X-Ray Inspection System for Bones FXR-BN40

It can detect leftover bones in meat processing, such as clavicles, fan bones, calcified bones, and others.

Detecting small, hard, and calcified bones in the poultry and meat processing industries is challenging due to their low density and varying shapes, influenced by factors such as age, breed, and specific cuts of meat.

The Foodman Dual Energy X-Ray Inspection System is a state-of-the-art solution tailored for the modern poultry industry. This X-ray machine effectively detects calcified, hard, and small bones in poultry products, including boneless raw meats like chicken breasts, legs, and wings, as well as processed items such as chicken nuggets, sausages, and meat patties.

By enhancing the detection of non-metallic contaminants, this system ensures quality and safety, enabling the accurate identification and removal of even the smallest foreign objects and bones.

APPLICATIONS

chicken breast

boneless chicken wings

sausages

meat patties

TECH SPECS

Model: FXR-BN40

X-Ray Tube:480W

X-ray Detector:0.1, 0.2, 0.4, 0.8mm TDI Dual Energy

Max Product Width:400mm

Max Product Height:170mm

Conveyor Belt Speed:5-40m/min

Sensitivity(mm)

Calcified bone: 1.0mm

Fan bone: 2.0 mm

Rib bone: 2.0 mm

Wishbone: 2.0 mm

Stainless Steel Wire: 0.2*2 mm

Stainless Steel Ball: 0.3 mm

Aluminum: 0.7 mm

Ceramic: 0.8mm

Glass: 0.8mm

Operation Display:17-inch colored touch screen, Windows System

Power Supply:AC220V, 2Kv, 50/60Hz

Rejector:Support various rejector

Waterproof:Level IP66

Operating Requirement Temperature:-10℃~40℃,Humidity:30%~90%

Main Structure: SUS304 Stainless Steel

Connectivity:Ethernet/IP (EIP)/USB/TCP/IP Modbus TCP/RTU

X-ray Emissions:< 1uSv/hr

KEY FEATURES

Dual Energy Technology

Employs progressive dual-energy X-ray technology to enhance the system’s capability to distinguish between bones and other low-density materials such as meat and cartilage.

Bone Detection Precision

Fitted with advanced detectors and algorithms, it is capable of identifying even the tiniest bones, ensuring the safety and quality of the product.

Durability and Hygiene

Constructed from robust materials, this system is designed for food-grade environments. Its waterproof and dustproof features facilitate easy maintenance.

Minimal False Reject Rates

By reducing false rejects, it optimizes production efficiency and enhances product yield, effectively minimizing waste.

Safe and Reliable

Our X-ray machine complies with food safety regulations, maintaining X-ray leakage below 1 μSv/hour to meet stringent FDA and CE standards. You can trust our system to uphold the highest food safety benchmarks.

High Throughput Efficiency

Tailored for large-scale poultry processing, the Foodman Dual Energy X-Ray Inspection System can inspect up to 120 pieces per minute. This high throughput reduces bottlenecks and increases overall productivity while ensuring accurate inspections.

What Makes FOODMAN X-RAY INSPECTION SYSTEM DIFFERENT?

Commitment to Safety