Foodman Vision Inspection System

The Foodman vision inspection system combines sensitive industrial cameras and AI algorithms for 360° online product sealing and coding inspection. It detects and removes 99.9% of defects, enhancing product quality. The system easily connects to existing production lines, making it ideal for the pharmaceutical, cosmetic, food, and beverage industries.

The Foodman Vision Inspection System is equipped with high-sensitivity industrial cameras and powerful AI algorithms, enabling 360° online inspection of product sealing, labeling, and coding. This advanced technology ensures unparalleled accuracy, identifying even the smallest defects to maintain product integrity.

With an impressive defect detection rate of 99.9%, the system guarantees superior quality control by identifying and removing defective products before they reach consumers. This high level of accuracy helps reduce waste, improve operational efficiency, and protect brand reputation.

Designed for versatility, the Foodman Vision Inspection System integrates effortlessly into existing production lines. Its adaptability makes it the perfect solution for the pharmaceutical, cosmetic, food, and beverage industries, ensuring high-quality standards across diverse product categories.

Key Functions

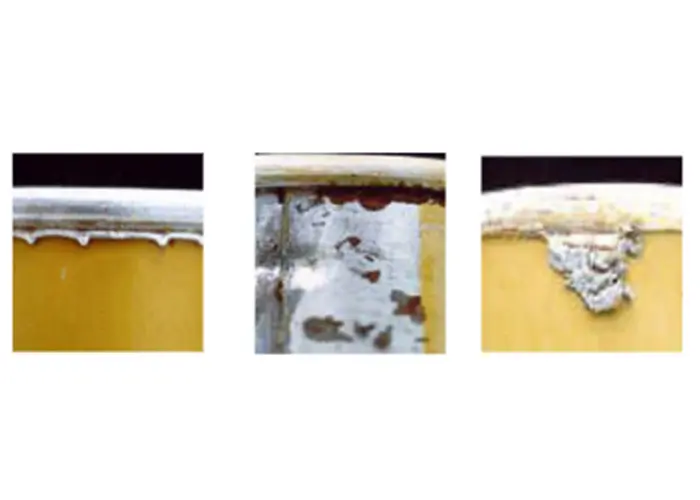

Appearance Damage Inspection

It detects scratches, dents, and cracks on aluminum cans, blister packs, and plastic containers

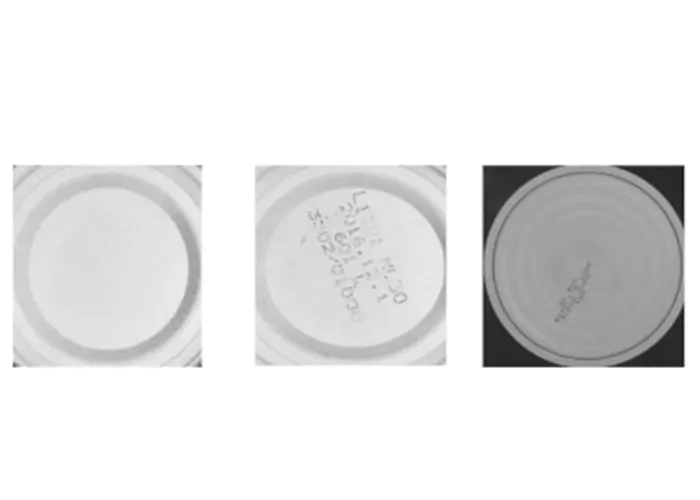

Label and Coding Inspection

It can inspect incorrect or missing labels and verify inkjet codes for presence, absence, and defects. It detects barcodes and 1D/2D codes effectively.

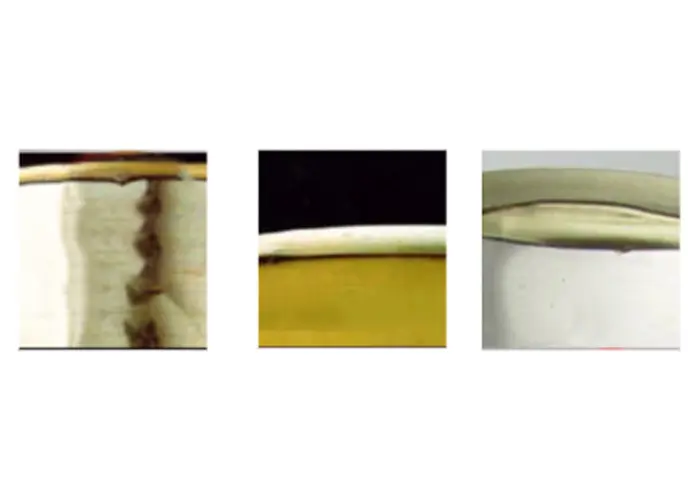

Seal Integrity Inspection

It inspects packaging seals (bottles, cans, bags) to prevent leakage and contamination, ensuring proper flatness and alignment for optimal performance and shelf life.

APPLICATIONS

canned Food

drug

shampoo

beverage

KEY FEATURES

Image Acquisition with Multi-Angle Cameras

The vision system leverages multiple strategically positioned cameras to capture comprehensive images of products as they move through the inspection zone, ensuring complete coverage from various angles.

Intelligent Data Analysis

Captured images are processed through advanced AI-powered deep learning algorithms, which identify product characteristics, detect defects, and generate precise data models for accurate recognition and sorting.

Automated Execution and Alerts

The system automatically eliminates defective products based on the analysis results and provides immediate alerts to operators, ensuring swift action and minimal disruptions to the production line.

Accelerated AI Modeling & FDM Vision

The Foodman AI algorithm efficiently builds an initial model using 1,000 samples and refines it into a complete data model within one week, significantly improving detection precision.

Real-Time Quality Control & Traceability

The intuitive HMI interface displays real-time inspection results, offers detailed visual reporting, and ensures easy management of images and data for seamless traceability.

Adaptable for Diverse Industries

Backed by 16 years of expertise, the FDM Vision Inspection System supports versatile applications across food, beverage, pharmaceutical, and cosmetic production lines, with customizable configurations to meet unique operational requirements.

What Makes FOODMAN X-RAY INSPECTION SYSTEM DIFFERENT?

Image acquisition

Data processing

Execution unit

AI image algorithm & FDM VISION

Real-time quality monitoring and traceability

Versatile Application Across Products

Ask for the Best Solutions

Please fill in the blank some basic informations we need. We give provide the best solution for your products.