Introduction: From Guesswork to Precision

Evolution of Fat-to-Lean Ratio Control in the Meat Industry — from Manual Estimation to Data-Driven Precision

For decades, controlling the fat-to-lean ratio in meat products was largely based on manual inspection and subjective judgment. Skilled butchers relied on visual cues and experience to estimate fat content, which often led to inconsistencies in quality. As consumer expectations and regulatory requirements became more demanding, these traditional approaches proved insufficient. The introduction of food X-Ray inspection technology revolutionized the process, enabling meat processors to replace guesswork with fat analysis that is accurate, repeatable, and verifiable.

Why “precision” Is the Key Differentiator in Today’s Competitive Meat Market?

In a market where customers expect consistent quality, even small deviations in fat-to-lean ratio can impact taste, texture, and market value. Retailers and export markets demand products that meet strict specifications, and failing to deliver can damage both profits and brand reputation. This is why precision has become the defining factor for success. Modern X-Ray inspection systems provide meat producers with the capability to monitor every product in real time, ensuring that fat levels are exactly within target ranges. By using X-Ray inspection equipment for continuous monitoring, companies can deliver consistency that sets them apart from competitors while meeting regulatory and customer standards.

Introduction to Fat Analysis X-Ray Inspection Systems as a Modern Solution for Accurate, Real-Time Measurement

The Fat Analysis X-Ray Inspection System combines advanced imaging technology with sophisticated software to deliver precise fat-to-lean measurements in seconds. Unlike traditional laboratory methods that require time-consuming sampling, an X-Ray inspection machine can scan 100% of products inline, providing immediate feedback to operators and automated trimming equipment. This real-time capability not only improves quality control but also reduces waste, optimizes raw material usage, and ensures compliance with both domestic and international standards. With food X-Ray inspection technology, meat processors can achieve a new level of operational efficiency and accuracy that was once impossible with manual methods.

The Science Behind Fat-to-Lean Ratio Detection

How X-Ray Energy Interacts Differently with Fat and Lean Muscle Tissue

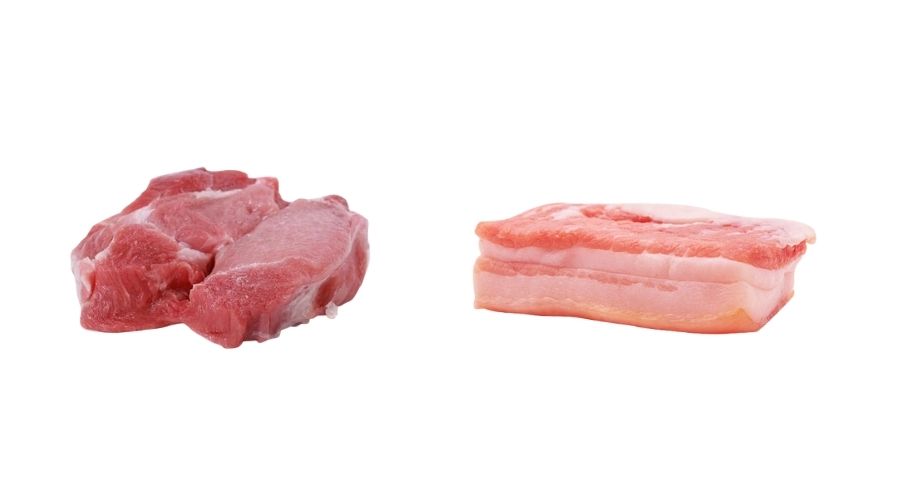

At the core of fat analysis using X-ray technology is the fundamental physics of how different tissues absorb and transmit X-ray energy. Fat and lean muscle differ not only in density but also in atomic composition—fat contains more lipids and less water compared to lean muscle, which is richer in protein and moisture. These differences mean that fat absorbs less X-ray energy, while lean muscle absorbs more.

When a food X-Ray inspection system scans a meat product, it sends X-ray beams through the item and records the varying absorption rates at each point. These absorption patterns are then processed into detailed images or data maps that show exactly where fat and lean meat are located. Importantly, this is a completely non-destructive process, so the product remains intact and ready for packaging or further processing.

Modern X-Ray inspection machines leverage high-resolution detectors and sophisticated algorithms to translate these absorption variations into precise fat-to-lean ratio measurements within fractions of a second. This speed and accuracy make the technology ideal for high-volume meat production where both efficiency and quality control are critical.

Dual-Energy X-Ray Technology: Separating Fat from Lean Using Density and Absorption Rate Differences

The Fat Analysis X-Ray Inspection System often uses dual-energy X-ray technology, which involves capturing two sets of images at different energy levels. This approach takes advantage of the fact that fat and lean tissues respond uniquely to each energy spectrum. Low-energy X-rays are more sensitive to fat content, while high-energy X-rays penetrate more deeply and are better suited to analyzing denser lean muscle.

By combining data from both energy levels, the X-Ray inspection system can calculate the exact proportions of fat and lean in each product, regardless of its shape, size, or surface irregularities. This dual-energy approach is significantly more precise than single-energy scanning and eliminates the inconsistencies often caused by lighting conditions, surface color, or operator subjectivity in visual checks.

Whether it’s deployed as a standalone X-Ray inspection machine or integrated into a broader X-Ray inspection equipment line, dual-energy technology ensures that every measurement is both objective and repeatable. This is crucial for meeting stringent customer specifications and maintaining consistent product quality in competitive markets.

Why Food X-Ray Inspection Is More Reliable Than Visual Checks or Manual Sampling

Historically, many meat processors relied on visual inspection or laboratory analysis of a small batch sample to estimate fat-to-lean ratios. While these methods can provide approximate results, they suffer from two major weaknesses—human subjectivity and limited coverage. Visual inspection depends on the skill and judgment of the operator, which can vary from person to person. Lab sampling, on the other hand, may only analyze a tiny fraction of a production lot, potentially missing significant variations within the same batch.

Food X-Ray inspection equipment addresses these shortcomings by scanning 100% of the production output in real time. Every piece is analyzed with the same accuracy, ensuring no product leaves the line without verification. The system automatically records and stores measurement data, creating a traceable quality history for each batch, which is invaluable for audits, customer verification, and compliance with food safety regulations.

By eliminating guesswork and dramatically improving coverage, X-Ray inspection systems reduce the risk of shipping non-compliant products, protect brand reputation, and give processors the ability to fine-tune operations for better yield and profitability.

Integrating Fat Analysis into Production Lines

How X-Ray Inspection Machines Can Be Seamlessly Installed in Existing Workflows

One of the key strengths of modern Fat Analysis X-Ray Inspection Systems is their ability to integrate effortlessly into existing meat processing lines. Designed with modularity and flexibility in mind, X-Ray inspection machines can be installed directly over conveyor belts or within packaging lines without requiring a complete overhaul of the production setup.

Manufacturers of X-Ray inspection equipment offer a variety of sizes and configurations, ensuring that the system fits seamlessly into different production environments—from high-volume beef processing plants to specialized seafood facilities. In most cases, installation can be completed with minimal disruption, and staff training ensures operators quickly adapt to the new system. This plug-and-play compatibility enables meat producers to start benefiting from advanced food X-Ray inspection technology almost immediately.

Inline Fat Analysis for Continuous Monitoring Without Slowing Production

Traditional fat analysis methods, such as lab testing, often interrupt production because they require physical sampling and time-consuming analysis. In contrast, X-Ray inspection systems offer inline fat analysis that continuously monitors every piece of meat moving along the production line.

By using advanced sensors and imaging software, the X-Ray inspection machine scans products at high speed without contact or damage, maintaining full throughput while providing accurate fat-to-lean ratio measurements in real time. This inline approach ensures that processors can make immediate adjustments to cutting, trimming, or blending operations without halting production. For busy facilities aiming to balance quality control with operational efficiency, inline food X-Ray inspection is a game-changer.

Data Workflow: Collecting, Analyzing, And Using Results for Automated Processing Adjustments

The value of a Fat Analysis X-Ray Inspection System extends beyond immediate measurement—it lies in its ability to generate actionable data. As products pass through the X-Ray inspection machine, each scan produces detailed records of fat distribution and lean content. This data is stored and analyzed automatically, creating a comprehensive quality log for every batch.

More advanced X-Ray inspection equipment can be linked directly to automated processing controls. For example, if fat levels exceed a preset threshold, the system can signal downstream machinery to adjust trimming blades, modify blending ratios, or redirect products for reprocessing. This closed-loop control not only ensures compliance with customer specifications but also minimizes waste and optimizes raw material usage.

By combining food X-Ray inspection technology with real-time analytics, meat producers can transform their production lines into smart, data-driven operations that deliver consistent quality, improved efficiency, and stronger profit margins.

Beyond Accuracy: The Business Impact

Minimizing Over-Trimming to Reduce Raw Material Loss

Fat analysis using food X-Ray inspection systems allows meat processors to precisely measure fat distribution in every cut. By doing so, X-Ray inspection machines can minimize over-trimming, ensuring that only the necessary fat is removed while preserving valuable lean meat. Integrating advanced X-Ray inspection equipment into production lines helps reduce raw material loss, optimize yield, and cut costs. Accurate fat analysis through X-Ray inspection not only prevents waste but also ensures that each portion meets the desired fat-to-lean ratio, enhancing overall operational efficiency. In addition, continuous monitoring enables processors to identify trends over time, adjust trimming guidelines dynamically, and prevent cumulative losses, maximizing both profitability and sustainability.

Ensuring Consistent Product Quality to Strengthen Brand Reputation

Consistency is key for building trust and maintaining a strong brand reputation in the meat industry. X-Ray inspection systems with integrated fat analysis ensure that every product meets exact fat specifications, regardless of batch variations. Food X-Ray inspection machines provide real-time, inline monitoring, enabling processors to detect inconsistencies before products leave the production line. By utilizing X-Ray inspection equipment, companies can guarantee uniform quality, increase customer satisfaction, and reinforce their reputation as a producer of safe, high-quality meat products. Moreover, documented X-Ray inspection results can be shared with distributors, retailers, and regulatory authorities, demonstrating a commitment to transparency and accountability. This builds confidence in the brand and can lead to stronger market positioning and long-term customer loyalty.

Reducing Risk of Recalls and Non-compliance Fines Through Precise Quality Control

Recalls and regulatory fines can be costly and damaging to a brand. X-Ray inspection systems with fat analysis capabilities reduce these risks by providing precise, non-destructive, and 100% inline inspection of all meat products. Food X-Ray inspection machines detect deviations from required fat levels early, ensuring compliance with national and international standards. Implementing X-Ray inspection equipment enables meat processors to maintain thorough documentation of quality metrics, enhance traceability, and demonstrate adherence to regulatory requirements. Additionally, integrated X-Ray inspection systems can alert operators to deviations immediately, allowing corrective actions before products reach the market. This proactive quality control not only safeguards product safety and corporate reputation but also strengthens operational resilience and reduces potential financial losses from recalls or customer complaints.

Versatility Across Product Types

Fat-to-Lean Ratio Control in Large Primal Cuts

Fat analysis X-Ray inspection systems excel at evaluating large primal cuts, such as beef loins, pork shoulders, and whole poultry portions. X-Ray inspection machines provide precise, non-destructive measurement of fat distribution across these sizable cuts, allowing processors to maintain consistent quality and achieve target fat-to-lean ratios. Using advanced X-Ray inspection equipment, meat producers can reduce manual trimming errors, optimize yield, and ensure that each cut meets customer specifications and regulatory standards. Food X-Ray inspection also helps identify internal fat pockets that are not visible externally, preventing inconsistencies in final products.

Application in Ground Meat and Processed Products

Ground meat and processed products present unique challenges due to their heterogeneous composition. Fat analysis through X-Ray inspection systems enables real-time monitoring of mixed meat batches, ensuring that the fat content remains consistent across each portion. Food X-Ray inspection machines can scan high-speed production lines, detecting deviations before packaging and distribution. Integrating X-Ray inspection equipment into processing lines ensures both accuracy and efficiency, while minimizing waste and rework. This application is especially critical for sausages, meatballs, and other value-added products where precise fat content is crucial for taste, texture, and labeling compliance.

Multi-protein Use Cases: Beef, Pork, Poultry, And High-Fat Seafood like Salmon

Modern X-Ray inspection systems are versatile across multiple protein types. Fat analysis using these machines is effective not only for beef, pork, and poultry but also for high-fat seafood such as salmon and mackerel. Each protein type has distinct density and absorption characteristics, which X-Ray inspection equipment can detect and analyze accurately. Food X-Ray inspection allows producers to maintain consistent fat levels regardless of protein source, enhancing product quality, meeting market standards, and providing traceable, reliable data for regulatory and customer assurance. This multi-protein capability makes X-Ray inspection systems indispensable for facilities handling diverse product lines.

Combining Fat Analysis with Other X-Ray Functions

Integrating Foreign Object Detection for Both Safety and Quality Assurance

Modern meat processors require more than just fat content measurement—they also need to ensure that every product is free from contamination. Advanced X-Ray inspection systems can combine fat analysis with foreign object detection, identifying metal, glass, bone fragments, or other hazardous materials in real time. By integrating both safety and quality assurance in a single X-Ray inspection machine, processors eliminate the need for separate equipment and additional handling steps. This dual-function approach in food X-Ray inspection not only boosts operational efficiency but also safeguards brand reputation by ensuring both product consistency and consumer safety.

Merging Weight Grading and Fat Analysis in a Single X-Ray Inspection System

In meat processing, both weight accuracy and fat-to-lean ratio control are critical to profitability and compliance. Modern X-Ray inspection equipment can merge weight grading and fat analysis into a single, streamlined process. This integration enables processors to check each product for weight precision while simultaneously verifying fat content, all in real time. By leveraging food X-Ray inspection technology for both tasks, companies can reduce waste, optimize raw material use, and deliver products that meet exact specifications. This combination also allows production lines to adjust cutting and portioning on the fly, ensuring maximum efficiency.

Centralized Data Collection for Production Optimization and Reporting

An X-Ray inspection system that integrates multiple functions becomes more than just a detection tool—it becomes a central hub for production data. Fat content results, weight grading metrics, and foreign object detection records can all be collected and analyzed in one platform. With centralized data from X-Ray inspection machines, processors can identify process inefficiencies, optimize line performance, and maintain full traceability for audits and customer reporting. This data-driven approach ensures that food X-Ray inspection is not only improving quality control but also supporting smarter business decisions and long-term operational excellence.

Future Trends in Precision Fat Control

AI-Powered Prediction of Fat Distribution Before Cutting

The next generation of X-Ray inspection systems will go beyond simple measurement—they will predict fat distribution before a cut is even made. By combining food X-Ray inspection technology with advanced artificial intelligence algorithms, processors can use both historical production data and real-time imaging to forecast the exact fat-to-lean ratio of each primal cut. This capability allows X-Ray inspection machines to guide cutting and trimming decisions with exceptional accuracy, ensuring optimal yield while minimizing costly errors. AI-driven fat analysis will also enable processors to adapt dynamically to variations in livestock, seasonality, or supplier quality, creating a more resilient and data-driven production workflow. In competitive markets, this predictive power can mean the difference between meeting or exceeding customer expectations.

Cloud-Based Analytics for Multi-site Quality Management

For meat producers operating across multiple facilities, centralized quality control is essential to maintaining consistent standards. Future X-Ray inspection equipment will seamlessly integrate with cloud-based analytics platforms, enabling instant sharing and comparison of fat analysis data between sites. With food X-Ray inspection results accessible from anywhere, production managers and quality control teams can identify trends, address deviations quickly, and ensure uniform compliance across regions. This approach supports not only regulatory adherence but also internal performance benchmarking, supplier evaluation, and predictive maintenance of X-Ray inspection machines. The combination of cloud storage, AI processing, and instant reporting turns raw inspection data into actionable business intelligence.

Sustainability Benefits: Reduced Waste, Improved Resource Efficiency

Modern consumers and retailers are increasingly demanding sustainable practices from meat suppliers, and advanced X-Ray inspection systems can directly contribute to these goals. Through precise fat analysis, processors can optimize trimming, portioning, and blending processes, reducing raw material waste and maximizing usable yield from each carcass. This not only cuts operational costs but also reduces the environmental footprint of production. When food X-Ray inspection is combined with other functions—such as foreign object detection, weight grading, and moisture content measurement—processors can achieve multiple quality and safety goals with a single X-Ray inspection machine, reducing equipment redundancy and energy consumption. The result is a leaner, more efficient, and more eco-friendly operation, aligning business performance with long-term sustainability strategies.

Conclusion

Recap: The Role of X-Ray Inspection Equipment in Precise Fat-to-Lean Ratio Control

Throughout this discussion, it’s clear that X-Ray inspection equipment plays a central role in achieving accurate and consistent fat-to-lean ratio control in meat processing. By using advanced fat analysis technology, meat producers can move beyond manual estimation and visual checks to precise, real-time measurements. Whether integrated as a standalone X-Ray inspection machine or as part of a larger X-Ray inspection system, these tools ensure that every cut meets the desired specifications while reducing waste and maximizing yield. Food X-Ray inspection not only supports product quality and brand reputation but also strengthens compliance with industry regulations—delivering measurable benefits across the entire production chain.

Call-to-Action: Why Now Is the Time for Meat Producers to Invest in Advanced Food X-Ray Inspection Technology

With consumer expectations, regulatory requirements, and market competition all on the rise, there has never been a better time for meat producers to adopt advanced food X-Ray inspection solutions. Investing in a modern X-Ray inspection system with integrated fat analysis capabilities allows processors to improve accuracy, increase operational efficiency, and meet sustainability goals. From detecting deviations in fat content to preventing costly recalls, today’s X-Ray inspection machines are more than just quality control tools—they are strategic assets for growth and competitiveness. The meat industry’s future belongs to producers who embrace data-driven precision, and advanced X-Ray inspection equipment is the key to staying ahead.

FAQ

Q: What is a Fat Analysis X-Ray Inspection System?

A: A Fat Analysis X-Ray Inspection System is specialized equipment that uses X-ray imaging to measure fat-to-lean ratios in meat products accurately and in real time.

Q: Is Fat Analysis X-Ray Inspection System safe for consumers?

A: Yes, Fat Analysis X-Ray Inspection System uses low radiation levels that are completely safe and do not affect food quality or taste.

Q: What types of meat products can benefit from fat analysis?

A: Fat analysis via X-Ray inspection equipment is effective for beef, pork, poultry, ground meat, processed products, and even high-fat seafood.