Introduction

Overview of Eco-Friendly Packaging Trends and Materials

In recent years, the food, beverage, and consumer goods industries have increasingly shifted towards eco-friendly packaging to reduce environmental impact and promote sustainability. Materials such as recycled plastics, rPET bottles, biodegradable films, and compostable laminates are becoming standard choices for manufacturers aiming to meet the growing demand for sustainable packaging. These materials help reduce plastic waste, lower carbon footprints, and support circular economy initiatives.

However, while the environmental benefits of these materials are significant, they also introduce new challenges for quality control and contaminant detection. Lightweight, multilayered, or recycled materials may have variable densities and compositions, which can complicate traditional inspection methods. To ensure that products remain safe and contaminant-free, manufacturers are turning to advanced X-Ray inspection machines and X-Ray inspection equipment.

Importance of Food and Product Safety in Sustainable Packaging

Ensuring food safety and product integrity is critical, even when using eco-friendly materials. Contaminants such as metal fragments, glass shards, stones, or plastic residues can inadvertently enter packaging during production or recycling processes. Undetected contaminants can pose serious risks to consumers and damage brand reputation, potentially resulting in costly recalls or regulatory penalties.

Traditional inspection methods may struggle to identify foreign objects hidden within multilayer or recycled packaging, highlighting the need for advanced food X-Ray inspection technologies. By leveraging X-Ray inspection systems, manufacturers can detect contaminants accurately and efficiently without compromising the structural integrity of eco-friendly packaging.

Role of X-Ray Inspection Machines and Systems

Modern X-Ray inspection machines play a crucial role in maintaining quality control for eco-friendly packaging. These machines use high-energy X-rays to scan packaged products, detecting both metallic and non-metallic foreign objects. Integrated X-Ray inspection equipment can perform real-time, high-speed inspections, making them suitable for large-scale production lines while minimizing production losses.

Advanced X-Ray inspection systems often include features such as dual-energy imaging and AI-assisted analysis, which enhance detection accuracy, reduce false positives, and adapt to variations in recycled or biodegradable materials. By implementing comprehensive food X-Ray inspection protocols, manufacturers can ensure contaminant-free products, uphold regulatory compliance, and reinforce consumer trust, all while supporting sustainability goals.

Common Contaminants in Eco-Friendly Packaging

Types of Contaminants

Even as the food, beverage, and consumer goods industries increasingly adopt eco-friendly packaging, the presence of contaminants remains a significant concern. Common foreign objects found in recycled plastics, rPET, and biodegradable films include metal fragments, glass shards, stones, plastic pieces, and residues from previous production cycles. These contaminants can compromise food safety, reduce product quality, and negatively impact brand reputation if left undetected.

Traditional visual inspection or manual methods often fail to detect small or hidden contaminants, particularly in thin, multilayered, or opaque packaging. Modern X-Ray inspection machines and X-Ray inspection equipment are therefore essential for comprehensive food X-Ray inspection. By leveraging X-Ray inspection systems, manufacturers can non-destructively scan packages for both metallic and non-metallic contaminants, ensuring every product meets rigorous quality control standards.

Challenges Specific to Eco-Friendly Packaging

While eco-friendly packaging contributes to sustainability goals, it introduces unique challenges for contaminant detection:

Recycled material variability: Differences in density and composition among recycled plastics and rPET batches affect X-Ray absorption, making contaminant detection more complex. Advanced X-Ray inspection machines allow operators to adjust sensitivity and imaging settings to handle these variations.

Transparency and thinness: Biodegradable films, lightweight plastics, and compostable laminates can obscure small contaminants, requiring high-resolution X-Ray inspection equipment for reliable detection.

Multilayer or composite packaging: Laminated films and composite layers used for barrier protection can mask foreign objects. Dual-energy X-Ray inspection systems are especially effective in penetrating multiple layers while maintaining detection accuracy.

Flexible packaging challenges: Wrinkles, folds, or irregular shapes in thin or soft eco-friendly packaging can cause false positives. AI-assisted X-Ray inspection machines help differentiate actual contaminants from harmless packaging artifacts.

By combining X-Ray inspection, X-Ray inspection machines, and X-Ray inspection equipment, manufacturers can overcome these challenges and maintain consistent safety standards even with complex eco-friendly materials.

Risks of Undetected Contaminants on Consumer Safety and Brand Reputation

Undetected contaminants in eco-friendly packaging can have severe consequences:

Consumer safety risks: Foreign objects such as metal, glass, stones, or plastic fragments can cause injury or health hazards, undermining consumer trust in both the product and the brand.

Brand reputation and financial impact: Product recalls, regulatory penalties, and negative media exposure can result in significant financial losses and long-term brand damage.

Regulatory compliance: Food and beverage products, pharmaceuticals, and cosmetics packaged in recycled or biodegradable materials must adhere to strict safety regulations. Implementing robust X-Ray inspection systems ensures compliance with global safety standards.

With advanced food X-Ray inspection, X-Ray inspection machines, and industrial X-Ray inspection equipment, manufacturers can reliably detect contaminants in eco-friendly packaging, reduce false positives, and maintain high-speed production without sacrificing quality control. These technologies not only safeguard consumers but also enhance brand trust while supporting sustainable manufacturing practices.

Advantages of X-Ray Inspection for Eco-Friendly Packaging

Non-Destructive Testing Preserving Packaging Integrity

One of the most significant benefits of using X-Ray inspection machines for eco-friendly packaging is their ability to perform non-destructive testing. Unlike traditional inspection methods, X-Ray inspection equipment can scan recycled plastics, rPET bottles, and biodegradable films without damaging the packaging. This ensures that delicate or multilayered sustainable packaging remains intact while detecting foreign objects such as metal fragments, glass shards, stones, or plastic residues.

Advanced X-Ray inspection systems allow for high-resolution imaging and precise sensitivity adjustments, making it possible to perform thorough food X-Ray inspection even on thin or flexible eco-friendly packaging. By preserving packaging integrity, manufacturers can maintain both product safety and environmental sustainability without generating unnecessary waste.

High-Speed Inspection Suitable for Modern Production Lines

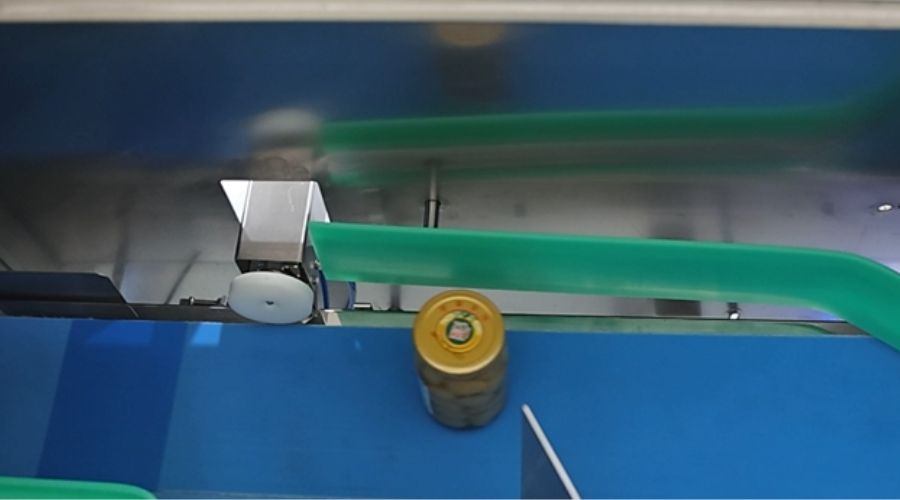

Modern production lines demand both speed and accuracy, and X-Ray inspection machines are designed to meet these requirements. High-speed X-Ray inspection equipment can inspect thousands of products per hour, including rPET bottles, recycled plastic containers, and biodegradable snack bags.

Integrated X-Ray inspection systems provide real-time imaging and automated analysis, allowing manufacturers to maintain throughput without sacrificing quality control. Implementing food X-Ray inspection at high-speed production lines ensures that contaminants are identified promptly while supporting efficiency and operational scalability in large-scale eco-friendly packaging operations.

Ability to Detect Metallic and Non-Metallic Contaminants

A key advantage of X-Ray inspection over traditional detection methods is its ability to identify both metallic and non-metallic contaminants. X-Ray inspection machines can detect a wide range of foreign objects, including metals, stones, glass, hard plastics, and dense residues that might be hidden in multilayer or opaque eco-friendly packaging.

Using dual-energy X-Ray inspection equipment and AI-assisted X-Ray inspection systems, manufacturers can differentiate between harmless packaging variations and true contaminants. This capability enhances food X-Ray inspection effectiveness, reducing false positives while ensuring that every packaged product leaving the production line meets strict safety and quality control standards.

Integration with Automated Rejection Systems for Efficiency

Many modern X-Ray inspection systems are equipped with automated rejection mechanisms. Once a contaminant is detected, the X-Ray inspection machine can automatically remove the affected eco-friendly packaged product from the production line. This minimizes human intervention, reduces inspection errors, and maintains continuous high-speed production.

The combination of X-Ray inspection equipment, automated rejection systems, and AI-assisted food X-Ray inspection allows manufacturers to optimize both safety and efficiency. This ensures that eco-friendly packaging is not only contaminant-free but also produced in a cost-effective, high-throughput, and sustainable manner.

Challenges in Inspecting Eco-Friendly Packaging

Variability in Recycled or Biodegradable Material Density

A major challenge in eco-friendly packaging inspection stems from the variability in material density. Recycled plastics, rPET bottles, and biodegradable packaging films often come from diverse sources, resulting in inconsistent thickness, internal structure, and X-Ray absorption properties. These variations make it more difficult for traditional inspection methods to reliably identify foreign objects or contaminants.

To address this, modern X-Ray inspection machines and X-Ray inspection equipment allow precise calibration for different material densities. Advanced X-Ray inspection systems can detect subtle differences between harmless packaging variations and actual contaminants, ensuring consistent food safety and quality control. Incorporating AI-assisted food X-Ray inspection further enhances accuracy, enabling manufacturers to manage variability in recycled or biodegradable materials effectively.

Multilayer or Opaque Packaging Complicating X-Ray Absorption

Eco-friendly packaging often utilizes multilayer films, laminated biodegradable materials, or colored plastics to enhance durability and barrier properties. While these innovations improve shelf life and reduce environmental impact, they also complicate contaminant detection. Multiple layers or opaque films can obscure small metal, glass, or stone fragments, challenging even high-end X-Ray inspection systems.

To overcome these issues, X-Ray inspection machines equipped with dual-energy imaging and real-time analysis can penetrate multiple layers without damaging the packaging. This allows for reliable food X-Ray inspection of rPET bottles, recycled plastics, and other sustainable packaging formats. Integrating X-Ray inspection equipment with automated rejection systems ensures that every contaminated product is removed while maintaining production efficiency and minimizing waste.

Minimizing False Positives and Avoiding Unnecessary Waste

False positives are another common challenge in inspecting eco-friendly packaging. Wrinkles, folds, multilayer overlaps, or thin biodegradable films can sometimes be misinterpreted as contaminants by less sophisticated inspection methods. Excessive false alarms can lead to unnecessary product rejection, increased material waste, and reduced production throughput.

High-precision X-Ray inspection systems with AI-assisted imaging algorithms can distinguish harmless packaging artifacts from actual foreign objects. Advanced X-Ray inspection machines and industrial X-Ray inspection equipment improve accuracy in detecting both metallic and non-metallic contaminants. This not only ensures food safety but also supports quality control, optimizes production efficiency, and reduces operational costs. Manufacturers can maintain high-speed inspection on modern production lines while achieving stringent regulatory compliance and sustainable manufacturing goals.

Best Practices for Effective X-Ray Inspection of Eco-Friendly Packaging

Calibrating X-Ray Inspection Machines for Different Eco-Friendly Materials

Effective X-Ray inspection begins with proper calibration of X-Ray inspection machines to account for the wide variety of eco-friendly packaging materials. Recycled plastics, rPET bottles, biodegradable films, and multilayer sustainable packaging can have different densities, thicknesses, and X-Ray absorption characteristics. Without precise calibration, even advanced X-Ray inspection equipment may misidentify harmless material variations as contaminants or miss small foreign objects entirely.

To ensure accurate food X-Ray inspection, manufacturers should implement material-specific calibration routines for every production batch. Advanced X-Ray inspection systems with dual-energy imaging and adjustable sensitivity can reliably detect metal, glass, stone, or plastic fragments while maintaining packaging integrity. By combining calibration with high-resolution imaging, producers can enhance quality control, reduce false positives, and optimize production efficiency on high-speed lines.

Regular Verification and Maintenance of X-Ray Inspection Systems

Maintaining consistent X-Ray inspection performance requires routine verification and maintenance of X-Ray inspection systems. Conveyor alignment, detector calibration, imaging software updates, and mechanical inspection of X-Ray inspection machines and X-Ray inspection equipment are all essential to ensure reliable contaminant detection.

Regular maintenance reduces downtime, prevents misreads, and maintains the accuracy of food X-Ray inspection, particularly when handling complex eco-friendly packaging such as multilayer films or laminated biodegradable materials. Scheduled verification ensures that the system continues to meet regulatory compliance standards, supports sustainable production practices, and protects consumer safety by preventing contaminated products from reaching the market.

Using AI-Assisted Detection to Distinguish Contaminants from Packaging Artifacts

Integrating AI-assisted detection into X-Ray inspection machines and X-Ray inspection systems is a best practice that significantly improves the accuracy of food X-Ray inspection. AI algorithms can differentiate between true contaminants and harmless packaging artifacts such as wrinkles, folds, or multilayer overlaps in eco-friendly packaging.

By combining AI with high-speed X-Ray inspection equipment, manufacturers can reduce false positives, minimize unnecessary product waste, and maintain high production efficiency. This approach ensures that both metallic and non-metallic contaminants are reliably detected while protecting the structural integrity of recycled plastics, rPET bottles, and biodegradable packaging. Advanced AI-assisted X-Ray inspection systems also support continuous monitoring, regulatory compliance, and consistent quality control, enabling sustainable packaging production that is both safe and efficient.

Industry Applications and Case Studies

Eco-Friendly Beverage Bottles (rPET)

The beverage industry has increasingly adopted eco-friendly packaging in the form of rPET bottles to reduce plastic waste and promote sustainable production practices. While recycled PET offers environmental benefits, the variability in material density and potential for hidden foreign objects make X-Ray inspection essential.

Using advanced X-Ray inspection machines and X-Ray inspection equipment, beverage manufacturers can perform food X-Ray inspection to detect metal fragments, glass shards, or other contaminants without damaging the bottles. Integrated X-Ray inspection systems ensure high-speed detection across production lines, maintaining quality control and regulatory compliance. Case studies show that implementing these systems has led to reduced recalls, improved product safety, and enhanced consumer trust in sustainable beverage packaging.

Biodegradable Snack and Food Packaging

In the snack and food industry, biodegradable packaging is becoming a preferred choice for eco-conscious brands. Thin films and multilayer biodegradable bags, while environmentally friendly, can make contaminant detection challenging.

High-precision X-Ray inspection machines and X-Ray inspection systems are used to inspect these lightweight, multilayer packages. Food X-Ray inspection ensures that both metallic and non-metallic contaminants are detected before the product reaches consumers. By integrating automated rejection and AI-assisted analysis, manufacturers maintain production efficiency and reduce false positives, supporting quality control while upholding sustainable packaging standards. Case studies demonstrate significant reductions in product recalls and increased operational efficiency in high-speed snack production lines.

Pharmaceutical or Cosmetic Packaging with Sustainable Materials

The pharmaceutical and cosmetic sectors have also embraced sustainable packaging solutions, including rPET containers, recycled plastics, and biodegradable films. Product safety in these industries is critical, as contaminants could pose severe risks to consumers.

Advanced X-Ray inspection equipment and X-Ray inspection systems provide non-destructive scanning of eco-friendly containers, enabling reliable contaminant detection and food X-Ray inspection for ingestible or topical products. AI-assisted X-Ray inspection machines allow high-speed monitoring of complex packaging shapes, multilayer materials, and opaque containers. Successful implementations have improved quality control, ensured regulatory compliance, and strengthened consumer confidence in brands adopting eco-friendly packaging.

Success Stories Showing Reduced Recalls and Improved Quality Control

Across multiple industries, from beverages to snacks to pharmaceuticals, the integration of X-Ray inspection systems and X-Ray inspection equipment has demonstrated measurable benefits. Companies report significant reductions in product recalls, improved contaminant detection, and enhanced food safety compliance.

For instance, beverage brands using X-Ray inspection machines for rPET bottles have reduced recall incidents by up to 30%, while snack manufacturers using food X-Ray inspection systems for biodegradable packaging have seen a 25% reduction in production waste. In the pharmaceutical sector, AI-assisted X-Ray inspection equipment has allowed high-speed inspection of sustainable packaging without compromising quality control. These case studies highlight the crucial role of X-Ray inspection in maintaining safety, efficiency, and sustainability in modern packaging operations.

Conclusion

Recap of Why X-Ray Inspection is Essential for Eco-Friendly Packaging Safety

In today’s manufacturing landscape, ensuring the safety and integrity of eco-friendly packaging is more critical than ever. Recycled plastics, rPET bottles, biodegradable films, and multilayer sustainable packaging all present unique challenges for contaminant detection. Advanced X-Ray inspection machines, X-Ray inspection systems, and X-Ray inspection equipment provide reliable, non-destructive scanning that can identify both metallic and non-metallic foreign objects.

Implementing food X-Ray inspection ensures that every product, whether it’s a beverage, snack, pharmaceutical, or cosmetic item, meets stringent quality control and food safety standards. By detecting contaminants early, manufacturers reduce the risk of recalls, protect brand reputation, and safeguard consumers. The combination of high-resolution X-Ray inspection, real-time monitoring, and automated rejection systems makes it possible to maintain production efficiency while guaranteeing contaminant-free sustainable packaging.

Emphasize the Role of Advanced Technology in Ensuring Efficiency, Regulatory Compliance, and Sustainability

Beyond safety, advanced technology plays a pivotal role in optimizing eco-friendly packaging production. AI-assisted X-Ray inspection systems allow manufacturers to differentiate subtle packaging variations from actual foreign objects, minimizing false positives and reducing material waste. High-speed X-Ray inspection machines integrated into modern production lines enhance production efficiency while maintaining rigorous regulatory compliance.

The adoption of X-Ray inspection equipment is also crucial for meeting global sustainability goals. By ensuring that rPET, recycled plastics, and biodegradable packaging are free from contaminants, manufacturers support sustainable packaging initiatives while delivering safe, high-quality products to the market. These technologies bridge the gap between environmental responsibility and consumer safety, proving that advanced X-Ray inspection is indispensable in modern packaging operations.

In conclusion, combining X-Ray inspection, AI-assisted detection, and high-speed inspection systems ensures that eco-friendly packaging not only meets food safety and quality control standards but also aligns with sustainability goals, reduces waste, and strengthens regulatory compliance. Advanced X-Ray inspection systems empower manufacturers to achieve the perfect balance of safety, efficiency, and environmental responsibility, making them an essential component of modern eco-friendly packaging production.

FAQ

Q1: Why is X-Ray inspection important for eco-friendly packaging?

A1: X-Ray inspection detects metallic and non-metallic contaminants in recycled plastics, rPET bottles, and biodegradable films, ensuring food safety, regulatory compliance, and product quality without damaging packaging.

Q2: Can X-Ray inspection machines detect contaminants in multilayer or opaque eco-friendly packaging?

A2: Yes. Modern X-Ray inspection equipment and systems, especially with dual-energy imaging, penetrate multilayer or opaque packaging to identify hidden foreign objects efficiently.

Q3: How does AI-assisted X-Ray inspection improve contaminant detection?

A3: AI algorithms distinguish between true contaminants and harmless packaging artifacts, reducing false positives, minimizing waste, and enhancing high-speed production line efficiency.