Introduction: Precision and Safety in Small-Scale Food Products

Growing Demand for Contamination-Free Grains, Nuts, and Seeds in Global Markets

In today’s competitive food industry, consumers and regulators expect grains, nuts, and seeds to be completely free of foreign objects. Export markets impose strict compliance requirements, and any contamination can lead to costly recalls or trade restrictions. This has fueled a rapid increase in the adoption of food X-Ray inspection solutions, which provide processors with the ability to maintain consistent quality while meeting the highest international safety standards.

Why These Products Present Unique Inspection Challenges Compared to Other Food Categories?

Grains, nuts, and seeds are small, irregular in shape, and vary in density, which makes traditional detection methods less effective. Metal detectors, for example, can miss non-metallic contaminants like glass, stones, or hard plastics. Moreover, high-speed bulk handling can make it harder to detect small foreign objects without slowing production. This is where an advanced X-Ray inspection system proves invaluable. By using density-based imaging, X-Ray inspection equipment can detect a wide range of contaminants, regardless of their shape or material composition, even in dense product flows.

The Role of X-Ray Inspection Systems in Setting New Safety and Quality Benchmarks

Modern X-Ray inspection machines go beyond basic contaminant detection—they also help verify product uniformity, identify damaged items, and ensure correct fill levels in packaging. For grains, nuts, and seeds, these capabilities translate into fewer defects reaching consumers, improved product consistency, and a stronger reputation for safety. By integrating a high-performance food X-Ray inspection solution into their processing lines, producers not only comply with safety regulations but also set themselves apart in a highly competitive market.

Understanding the Contamination Risks in Grain, Nut, and Seed Processing

Common Foreign Objects: Stones, Glass Shards, Metal Fragments, Dense Plastics

In the processing of grains, nuts, and seeds, contamination can take many forms, each with its own challenges for detection and removal. Common threats include stones from harvesting, glass shards from broken containers, metal fragments from machinery, and dense plastics from packaging or storage equipment. Even seemingly harmless materials, such as hardened soil clumps or shell debris, can pose a risk if undetected.

These contaminants are often small yet hazardous, capable of damaging processing machinery, injuring consumers, or causing large-scale product recalls. Traditional detection methods—such as manual sorting or basic metal detectors—often fail to identify low-density and non-metallic objects. This is why food X-Ray inspection technology has become indispensable in modern facilities. A high-performance X-Ray inspection machine can scan products in real time, detecting density variations that reveal even the tiniest contaminants, ensuring the highest level of safety and compliance with both domestic and international food safety regulations.

Sources of Contamination in Harvesting, Transportation, and Processing

Contamination risks can occur at multiple stages of the supply chain, making a single-point solution insufficient. During harvesting, crops may be collected along with soil, stones, and other natural debris. In transportation, poor handling, exposure to external environments, or damaged containers can lead to additional contamination. Storage and packaging facilities may introduce new hazards, such as plastic fragments or glass particles from nearby processes.

Within processing plants, mechanical wear and tear is a frequent culprit—loose screws, broken blades, or deteriorated conveyor belts can lead to dangerous metal fragments entering the product flow. Without advanced inspection, these contaminants may go unnoticed until the final product reaches consumers. An integrated X-Ray inspection system provides a preventive safeguard by performing continuous, high-accuracy scans at critical control points. By strategically placing X-Ray inspection equipment before packaging or blending stages, manufacturers ensure that every batch leaving the facility meets the highest safety standards.

How Undetected Contaminants Can Impact Brand Trust and Export Compliance

The consequences of undetected contaminants extend far beyond immediate safety hazards. A single incident can trigger costly recalls, negative media coverage, and lasting consumer distrust. Once brand reputation is damaged, rebuilding confidence can take years and require significant investment in marketing and compliance programs.

For companies engaged in export, the risks multiply. International buyers and regulatory bodies enforce strict safety requirements, and even one failed inspection can result in shipment rejections, financial penalties, or blacklisting from key markets. For example, a contamination issue in a shipment of nuts could result in an entire container being destroyed, causing direct revenue loss and potential breach of supply contracts.

Deploying food X-Ray inspection solutions not only helps meet the most stringent global safety standards but also positions a brand as a leader in quality assurance. By using advanced X-Ray inspection machines capable of detecting a wide range of contaminants—metallic and non-metallic alike—producers can guarantee consistent quality, protect their reputation, and maintain full export compliance. This proactive approach sends a strong signal to buyers and consumers that safety, efficiency, and product integrity are non-negotiable priorities.

How X-Ray Inspection Works for Small-Particulate Food Products

Principles of Density-Based Detection in Bulk Flow Products

X-Ray inspection technology operates on the principle of detecting differences in density between the target food product and any foreign materials that may be present. In small-particulate products such as grains, nuts, and seeds, contaminants often have a density that differs from the surrounding food, even when they are similar in size and shape. By passing the product through an X-Ray inspection system, the equipment captures high-resolution images of the bulk flow and analyzes variations in absorption rates.

For example, a tiny stone mixed in with rice kernels or a glass shard hidden among sunflower seeds will absorb X-rays differently than the food itself. This density-based detection enables food X-Ray inspection to identify both metallic and non-metallic contaminants—something that traditional metal detectors cannot achieve. The result is a significant improvement in safety, quality, and compliance for bulk product manufacturers.

Differences Between Belt-Type and Gravity-Fed X-Ray Inspection Equipment

When choosing the right X-Ray inspection machine for small-particulate food products, the configuration matters. Belt-type systems are ideal for continuous-flow inspection, where products move steadily across a conveyor belt. This setup allows the X-Ray inspection equipment to scan evenly distributed product layers, making it suitable for nuts, dried fruits, and mixed grains where even coverage is important.

Gravity-fed systems, on the other hand, are designed for free-falling products such as seeds, powders, or small kernels. In these systems, the bulk product flows through a vertical inspection chamber, allowing contaminants to be detected mid-air before they reach packaging or blending stages. Food X-Ray inspection solutions in gravity-fed form are particularly effective in high-speed processing lines, as they maintain throughput without sacrificing detection sensitivity. Choosing between these systems depends on production layout, product type, and desired inspection points within the processing line.

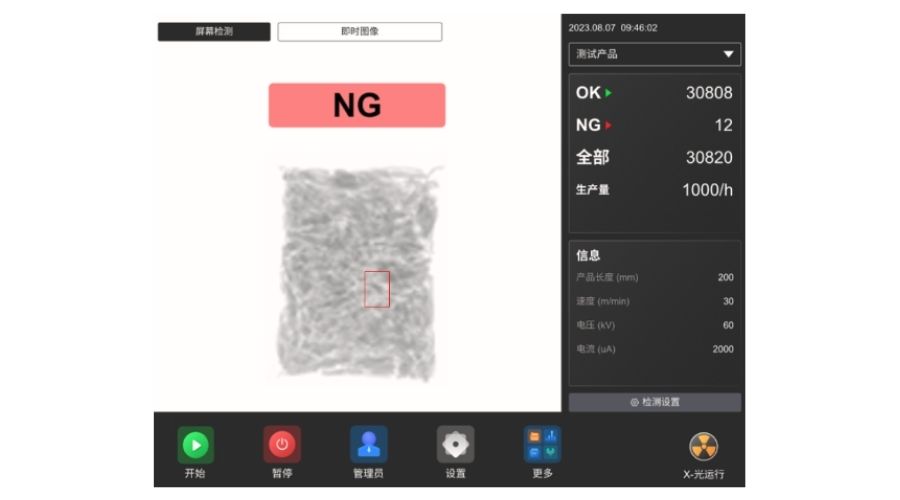

Image Processing and AI Algorithms for Identifying Irregular Particles

Modern X-Ray inspection systems rely on more than just hardware; advanced software plays a critical role in achieving high detection accuracy. Using AI-powered image processing algorithms, food X-Ray inspection machines can distinguish between harmless product variations and genuine contaminants. This minimizes false rejects while maintaining stringent quality control.

For example, an X-Ray inspection machine equipped with AI can learn to differentiate a nut shell fragment from a stone or identify a piece of dense plastic hidden among chia seeds. By analyzing shape, density distribution, and image contrast in real time, the X-Ray inspection equipment ensures contaminants are identified quickly and precisely.

In addition, image records from the inspection process can be stored for traceability, helping processors meet compliance requirements and investigate quality incidents. As AI technology continues to advance, the capabilities of X-Ray inspection for small-particulate food products will only become more powerful, offering processors a reliable way to maintain safety, efficiency, and brand integrity in competitive markets.

Integration into Modern Processing Lines

Matching Throughput Speeds Without Production Delays

In high-volume grain, nut, and seed processing facilities, maintaining line speed is just as important as maintaining quality. Modern X-Ray inspection systems are engineered to match the throughput of fast-moving production lines without creating bottlenecks. Whether processing several tons of raw materials per hour or handling high-speed packaging operations, an X-Ray inspection machine can operate continuously without slowing production.

This capability is critical in competitive markets, where even a short downtime can result in significant losses. Food X-Ray inspection technology uses high-speed image capture and real-time analysis to ensure that every batch is inspected instantly. As a result, processors can achieve both maximum productivity and uncompromised safety.

Configurations for Raw Material Intake, Pre-Cleaning, and Final Packaging Stages

One of the strengths of X-Ray inspection equipment is its flexibility in installation points across the production line. At the raw material intake stage, an X-Ray inspection system can act as the first safeguard, detecting large contaminants before they enter storage or pre-cleaning processes. This prevents downstream machinery damage and reduces the risk of cross-contamination.

During pre-cleaning, food X-Ray inspection ensures that partially processed grains, nuts, or seeds are free from stones, glass, and metal fragments, complementing traditional sieving and air classification systems. At the final packaging stage, X-Ray inspection machines perform a last quality check, identifying any contaminants that may have slipped through earlier stages. This multi-point integration approach provides comprehensive protection for both domestic and export markets.

Combining X-Ray Inspection with Other Sorting Technologies for Maximum Efficiency

While X-Ray inspection excels at detecting density-based contaminants, combining it with other sorting technologies can further enhance product quality. For instance, optical sorters can identify and remove discolored or defective items, while metal detectors can serve as an additional safety net for certain metallic hazards.

Integrating X-Ray inspection equipment with such systems creates a multi-layered defense strategy. In a grain or nut processing plant, for example, optical sorting might remove visibly damaged kernels, while the X-Ray inspection machine identifies hidden foreign objects invisible to the naked eye. This synergy ensures that only safe, high-quality products reach consumers, helping manufacturers build trust and maintain compliance with stringent international standards.

Key Features That Make the Difference

High-Resolution Imaging for Small or Low-Density Contaminants

One of the defining advantages of modern X-Ray inspection systems is their ability to detect even the smallest or most challenging contaminants in grains, nuts, and seeds. High-resolution imaging technology, combined with advanced detectors, allows an X-Ray inspection machine to identify low-density materials such as thin plastic films, small bone fragments, or lightweight stones that would pass unnoticed by traditional metal detection.

In food X-Ray inspection, precision is critical—especially when dealing with products that are small, irregular in shape, and often packed in bulk. By leveraging high-resolution sensors and sophisticated image processing algorithms, X-Ray inspection equipment ensures that even sub-millimeter foreign objects are detected before products reach consumers. This capability is vital for meeting both local and international safety requirements.

Multi-Product Adaptability for Seasonal or Mixed-Line Production

Grain, nut, and seed processors often handle different products depending on seasonal availability or market demand. A key benefit of advanced X-Ray inspection machines is their adaptability. With customizable settings and automatic calibration, a single X-Ray inspection system can be quickly adjusted to handle various product types—whether large nuts, fine seeds, or mixed batches—without sacrificing accuracy.

This flexibility makes food X-Ray inspection ideal for facilities running mixed production lines or switching products frequently. X-Ray inspection equipment can store inspection profiles for different products, allowing for fast changeovers and reducing downtime. This means processors can maintain efficiency while ensuring each product type receives the same level of contamination control.

Real-Time Rejection Systems That Minimize Product Waste

An effective X-Ray inspection system does more than detect contaminants—it also removes them with minimal impact on good product. Integrated real-time rejection systems can isolate and eject only the affected portion, rather than discarding an entire batch. This targeted removal is especially valuable in bulk processing, where product waste can significantly affect profit margins.

Modern X-Ray inspection machines feature high-speed reject mechanisms synchronized with detection results, ensuring contaminants are removed instantly without slowing production. By combining precision detection with efficient rejection, food X-Ray inspection helps manufacturers protect both their bottom line and their brand reputation. With this approach, safety and sustainability go hand in hand, delivering high-quality products while reducing unnecessary waste.

Benefits Beyond Contaminant Detection

Monitoring Product Shape, Uniformity, and Size Grading

Modern X-Ray inspection systems are no longer limited to detecting foreign objects—they have evolved into multifunctional quality control tools. In grain, nut, and seed processing, maintaining consistent product size and shape is essential for both visual appeal and downstream processing efficiency. With advanced imaging capabilities, an X-Ray inspection machine can monitor product uniformity in real time, identifying undersized, oversized, or irregularly shaped items.

This allows processors to use X-Ray inspection equipment not only for safety but also for grading and sorting purposes. For instance, premium export nuts can be separated from broken or uneven ones, ensuring consistent quality across shipments. This integrated approach makes food X-Ray inspection a valuable asset for producers aiming to meet strict quality standards in both domestic and international markets.

Reducing Customer Complaints and Returns

Product recalls, customer complaints, and returns can be costly—not just financially, but also in terms of brand reputation. By using an advanced X-Ray inspection system, manufacturers can significantly reduce the chances of defective products reaching the market. Whether it’s removing a foreign object or ensuring product consistency, the preventative role of food X-Ray inspection directly translates into fewer consumer issues and higher satisfaction rates.

An X-Ray inspection machine also helps businesses avoid the hidden costs associated with processing customer claims, handling replacements, and managing damage control. Over time, this proactive quality assurance builds consumer trust and reinforces a brand’s commitment to delivering safe, reliable products.

Supporting Traceability with Automated Image and Data Records

In today’s global food industry, traceability is a key factor in meeting regulatory compliance and maintaining transparency. Modern X-Ray inspection equipment is equipped with automated image capture and data logging features. Every product scan can be archived, creating a verifiable record of inspection results.

This data can be used for internal quality control reviews, audits, or as proof of compliance for export regulations. For processors of grains, nuts, and seeds, this level of documentation is invaluable—especially when dealing with high-value products or navigating international trade requirements. By integrating food X-Ray inspection into the production line, companies can ensure that every batch meets stringent safety and quality criteria, while also having the records to back it up.

ROI and Competitive Advantage

Cost Savings from Reduced Recalls and Improved Yield

Investing in a modern X-Ray inspection system delivers measurable financial benefits for producers of grains, nuts, and seeds. Contamination incidents can lead to costly recalls, product waste, and production downtime. By integrating food X-Ray inspection into the production line, companies can identify foreign objects and quality inconsistencies in real time, preventing defective batches from progressing further.

An advanced X-Ray inspection machine not only reduces the risk of recalls but also minimizes product losses caused by improper sorting or undetected defects. With high-speed detection and automated rejection, X-Ray inspection equipment ensures that only compliant products reach packaging and distribution. Over time, these efficiencies translate into significant cost savings, improving overall yield and maximizing return on investment.

Building Stronger Relationships with Retailers and Importers

Retailers and importers increasingly demand strict compliance with safety and quality standards. Demonstrating the use of advanced X-Ray inspection systems provides concrete evidence of a producer’s commitment to food safety. Food X-Ray inspection helps manufacturers meet stringent regulations, avoid shipment rejections, and consistently deliver high-quality products.

This reliability fosters stronger relationships with buyers, enhancing trust and increasing the likelihood of long-term contracts or preferential terms. Companies that implement X-Ray inspection machines as part of their quality control protocol differentiate themselves in the supply chain, showcasing transparency, accountability, and a proactive approach to risk management.

Positioning as a Premium, Safety-Focused Brand

In competitive markets, safety and quality are critical brand differentiators. Incorporating X-Ray inspection equipment into processing lines positions a company as a premium, safety-focused brand. Consumers increasingly seek assurance that their food is free from contaminants, and food X-Ray inspection offers visible, verifiable protection.

By promoting the use of X-Ray inspection systems in marketing and product labeling, producers can highlight their investment in advanced technology and unwavering commitment to quality. This positioning not only appeals to safety-conscious customers but also strengthens brand loyalty, enhances market share, and provides a competitive edge over companies relying solely on traditional inspection methods.

Conclusion

Reinforcing the Importance of X-Ray Inspection in Meeting Industry Demands

In the processing of grains, nuts, and seeds, maintaining product safety, quality, and consistency is paramount. Food X-Ray inspection has proven to be a vital technology for addressing these challenges. By using an advanced X-Ray inspection system, manufacturers can detect a wide range of contaminants—including stones, glass shards, metal fragments, and dense plastics—at every stage of production. X-Ray inspection machines provide non-destructive, real-time monitoring, ensuring that even small or low-density foreign objects are identified and removed efficiently. The integration of X-Ray inspection equipment into processing lines not only enhances safety but also supports compliance with international food safety standards, helping businesses meet both regulatory requirements and consumer expectations.

Encouraging Early Adoption to Future-Proof Processing Operations

Adopting X-Ray inspection systems early in the production line offers a significant competitive advantage. Modern X-Ray inspection machines equipped with AI algorithms, high-resolution imaging, and real-time rejection systems allow processors to future-proof their operations. Early adoption ensures that quality control measures can scale with increasing production volumes, seasonal variations, or new product types. By leveraging advanced X-Ray inspection equipment, manufacturers can stay ahead of emerging contamination risks, optimize throughput, and minimize downtime, making their operations more resilient and adaptable in the evolving food industry.

Final Call-to-Action for Upgrading to Advanced Inspection Systems

For processors looking to elevate safety, efficiency, and product quality, upgrading to state-of-the-art food X-Ray inspection technology is essential. Investing in modern X-Ray inspection machines or integrated X-Ray inspection systems ensures accurate detection of foreign objects, supports regulatory compliance, and enhances brand trust among consumers and trading partners. By implementing advanced X-Ray inspection equipment, grain, nut, and seed processors can achieve higher yields, reduce recalls, and maintain consistent quality across all production batches. The time to act is now—embrace cutting-edge X-Ray inspection solutions to secure safer, smarter, and more efficient processing operations.

FAQ

Q: Why are grains, nuts, and seeds more challenging to inspect compared to other food products?

A: Their small, irregular shapes and density variations make traditional detection methods less effective, especially for non-metallic contaminants like glass or stones.

Q: What types of contaminants can X-Ray inspection systems detect in bulk grain, nut, and seed processing?

A: They can detect stones, glass shards, metal fragments, dense plastics, and even low-density foreign materials that other systems miss.

Q: Can X-Ray inspection systems adapt to different product types in seasonal or mixed-line production?

A: Yes, modern systems feature multi-product adaptability with customizable profiles, enabling fast changeovers without sacrificing accuracy.