Snack Industrial Solution

This food X-Ray machine is ideal for inspecting a wide range of snack products, such as cheese, crackers, chips, and other similar packaged goods. It is engineered to detect any foreign objects, ensuring the safety and quality of each product before it reaches consumers.

Introduction to Snack Industry Challenges

Diverse Product Shapes and Sizes

Snacks come in various shapes and sizes, from flat chips to round nuts, which makes consistent detection challenging. X-ray inspection systems address this by using adaptive imaging algorithms that adjust to different product shapes, ensuring thorough inspection regardless of form.

Low-Density Contaminant Detection

Snacks often encounter contaminants like plastic fragments, stones, and small glass pieces, which can be difficult to detect due to their low density. Advanced X-ray systems employ high-sensitivity sensors and dual-energy imaging to enhance detection of these low-density contaminants, providing thorough protection.

Multi-Layered and Metalized Packaging

Many snacks are packaged in multi-layered plastic or metalized film, which can obstruct traditional inspection methods. X-ray technology can penetrate complex packaging, allowing accurate detection of foreign objects even within challenging packaging materials.

Detection Consistency Across Varying Densities

Snack foods range from light, airy products to dense nut-based items, making it difficult to detect contaminants consistently. X-ray systems with dual-energy technology enable reliable detection across products of varying densities, adapting imaging settings based on density fluctuations.

Minimizing False Rejects in Irregular Products

The irregular shapes and sizes of some snacks can trigger false rejects, leading to unnecessary waste and added costs. Advanced X-ray systems use intelligent software to differentiate between actual contaminants and harmless product variations, thereby reducing false rejects and minimizing waste.

High-Speed Processing Needs

Snack production lines often operate at very high speeds, which can compromise inspection accuracy if systems aren't optimized for fast throughput. X-ray inspection systems designed for high-speed environments maintain accurate detection without slowing down the production line, ensuring both efficiency and safety.

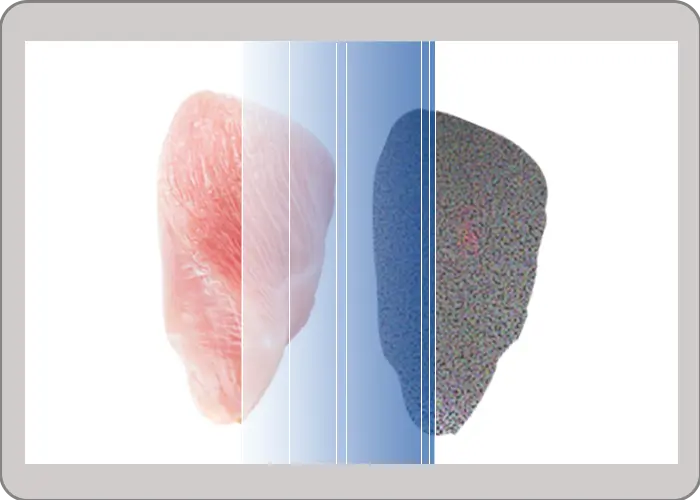

Core Technologies of Snack X-Ray Inspection Systems

FDX

Foodman employs FDX technology, which integrates industry-leading dual-energy TDI high-resolution detectors with advanced dual-energy image analysis algorithms and deep learning techniques. This combination enables Foodman systems to perform precise material analysis, identify low-density impurities, and detect morphological features with exceptional accuracy. By utilizing FDX technology, Foodman enhances the detection capabilities of its X-ray inspection systems, ensuring higher efficiency, reliability, and safety in food processing and packaging.

FIAP

Foodman utilizes FIAP, which leverages advanced AI algorithms and deep learning techniques to enhance detection performance. By analyzing a vast amount of image data, FIAP significantly improves processing speed and detection accuracy. This technology ensures that Foodman’ s X-ray inspection systems can detect even the most subtle irregularities in food products, providing faster, more reliable results while maintaining the highest standards of quality and safety in food production.

AI

Foodman incorporates advanced AI technology into its systems to optimize detection and quality control. By utilizing AI algorithms, Foodman’ s X-ray inspection systems can analyze vast amounts of data quickly and accurately. The AI-driven approach enhances the system’s ability to identify even the smallest contaminants or irregularities in food products, improving detection precision and operational efficiency. This integration of AI ensures consistent, high-quality results while reducing human error, making Foodman a trusted solution for food safety and quality assurance.

Choose the Right Detect Machine for Your Snack Line

Overview of different Foodman X-ray machines suitable for various snack types

X-Ray Inspection System For Small Sachets

This X-ray machine is ideal for inspecting a wide range of snack in small sachets. compact design and space saving.

X-Ray Inspection System For Packaged Products

This X-ray machine is ideal for inspecting snacks packaged in the majority of the bags and boxes.

X-Ray Inspection System For Large Products

This food X-Ray machine which have large aperture, works perfectly with items such in cartons or boxes.

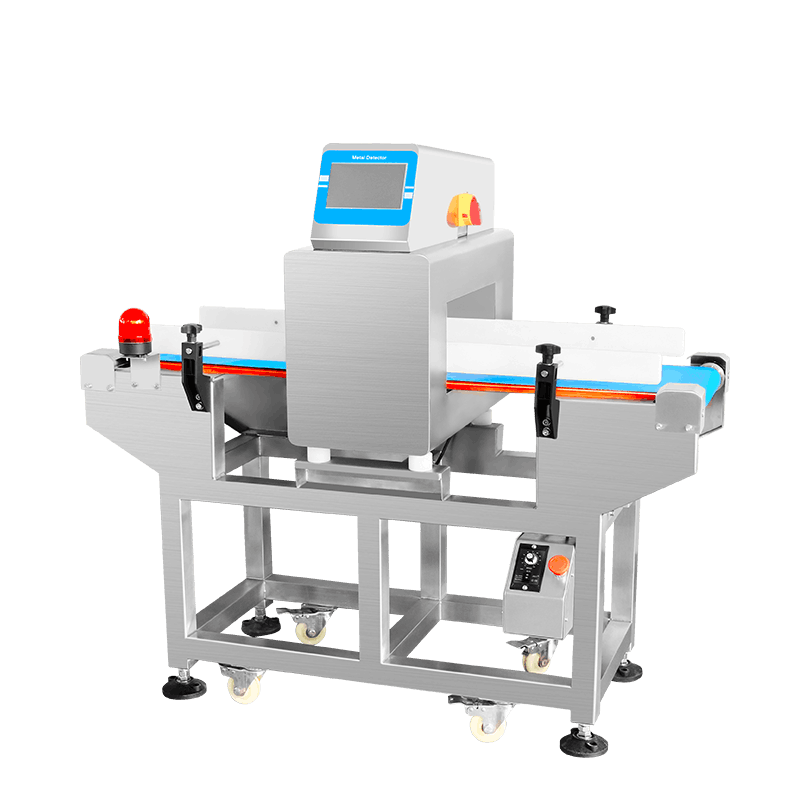

Metal Detector for Aluminum Foil Packaged Products

This machine is specially designed to detect metallic impurities or contaminants in snack foods wrapped in aluminum foil, such as coffee, candy, chocolate, cocoa powder, etc.

Foodman Amazing Clients

Ask for the Best Solutions

Please fill in the blank some basic informations we need. We give provide the best solution for your products.